Clamping device for nail driving

A clamping device and nail technology, which is applied in distribution devices, nail distributors, packaging, etc., can solve the problems of improper force control, low work efficiency, inconsistent nail depths, etc., and achieve the effect of consistent depth and convenient portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

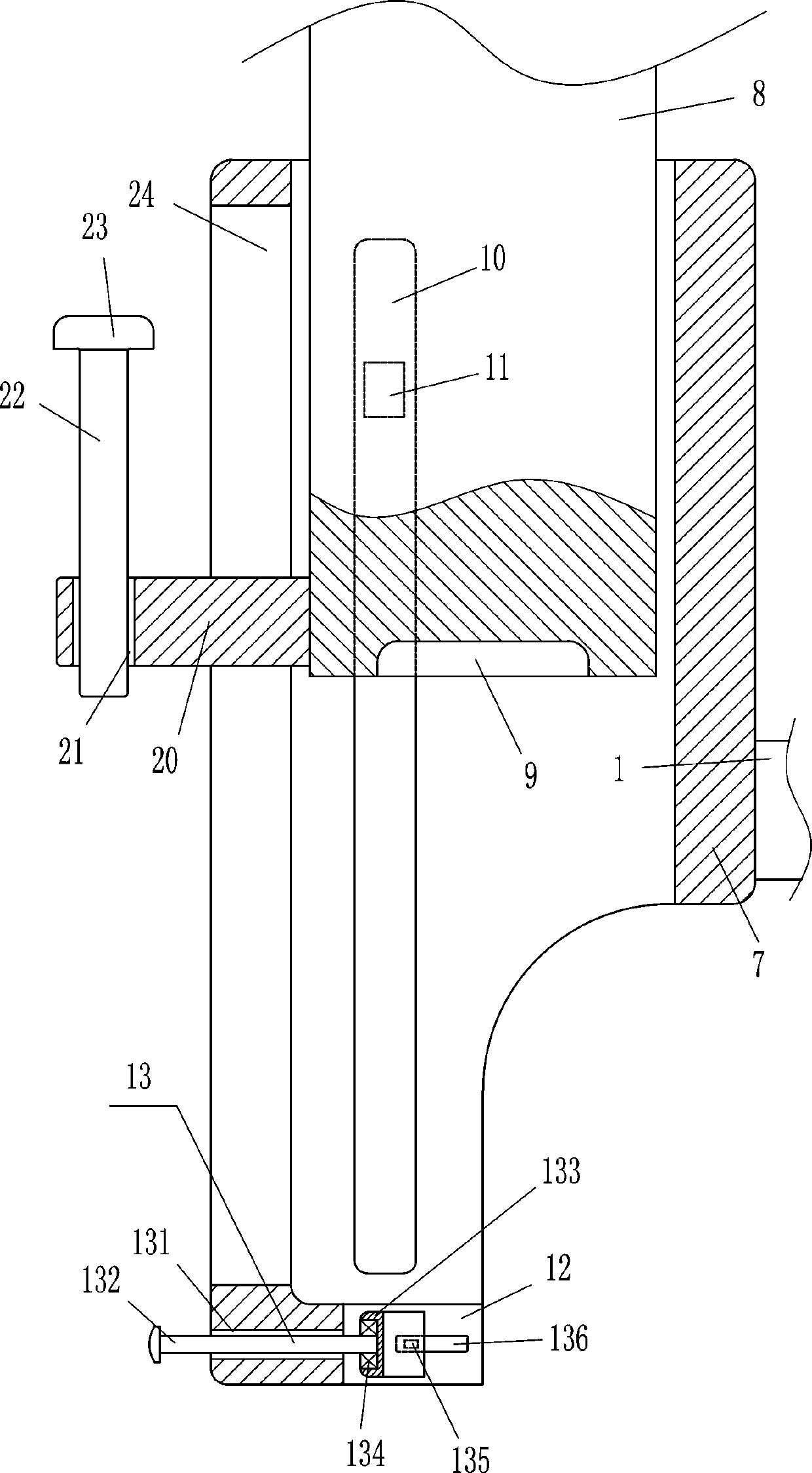

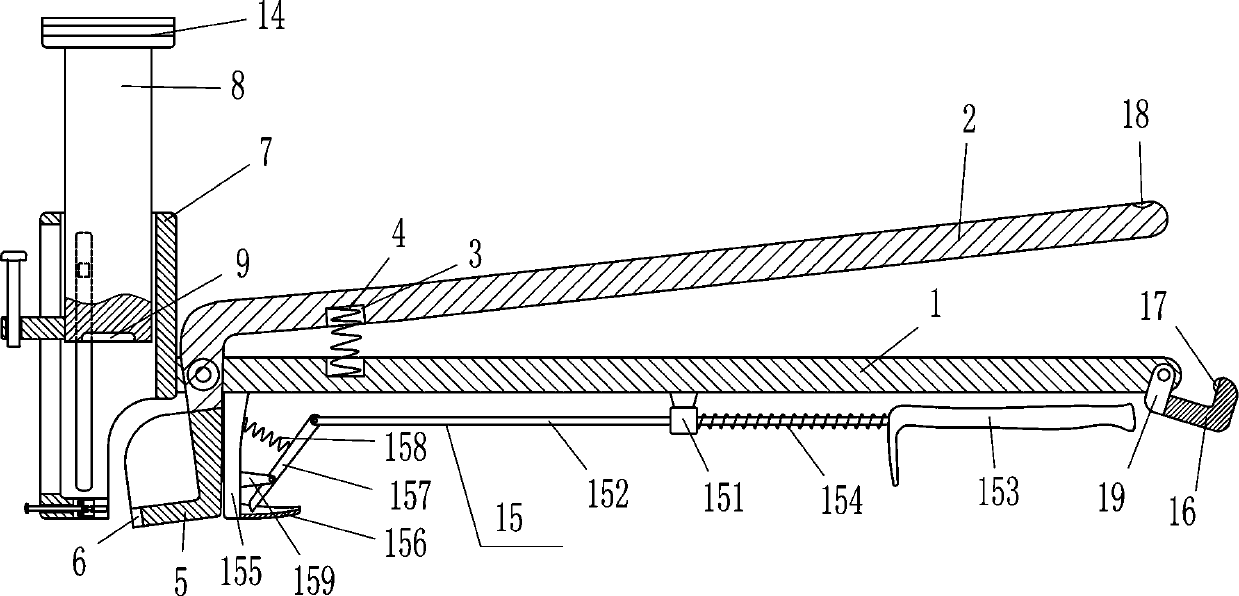

[0015] A clamping device for nailing, such as Figure 1-2 As shown, it includes a grip bar 1, a swing bar 2, a first spring 4, an L-shaped frame 5, a sleeve 7, a cylinder 8, a vertical slider 11, an adjustment device 13 and a rubber block 14, and the front side of the grip bar 1 The left side is hinged with a swing rod 2, the left side of the top of the swing rod 2 and the top left side of the grip rod 1 are provided with a first groove 3, and the bottom of the first groove 3 below is connected to the top of the first groove 3 above. The first spring 4, the L-shaped frame 5 that can be clamped by nails is installed on the bottom end of the swing rod 2, the L-shaped frame 5 is connected with the swing rod 2 through bolt connection, and the left side of the L-shaped frame 5 has a card slot 6 , the sleeve 7 is installed on the left end of the grip rod 1, the sleeve 7 is connected with the grip rod 1 by welding, the right side of the sleeve 7 is open, the sleeve 7 cooperates with ...

Embodiment 2

[0017] A clamping device for nailing, such as Figure 1-2 As shown, it includes a grip bar 1, a swing bar 2, a first spring 4, an L-shaped frame 5, a sleeve 7, a cylinder 8, a vertical slider 11, an adjustment device 13 and a rubber block 14, and the front side of the grip bar 1 The left side is hinged with a swing rod 2, the left side of the top of the swing rod 2 and the top left side of the grip rod 1 are provided with a first groove 3, and the bottom of the first groove 3 below is connected to the top of the first groove 3 above. The first spring 4, the L-shaped frame 5 that can clamp nails is installed on the bottom end of the swing rod 2, the left side of the L-shaped frame 5 has a card slot 6, the sleeve 7 is installed on the left end of the grip bar 1, and the sleeve 7 is on the right The side is open, and the sleeve 7 cooperates with the L-shaped frame 5. There is a through groove 12 on the right side of the lower part of the sleeve 7, and an adjustment device 13 is a...

Embodiment 3

[0020] A clamping device for nailing, such as Figure 1-2 As shown, it includes a grip bar 1, a swing bar 2, a first spring 4, an L-shaped frame 5, a sleeve 7, a cylinder 8, a vertical slider 11, an adjustment device 13 and a rubber block 14, and the front side of the grip bar 1 The left side is hinged with a swing rod 2, the left side of the top of the swing rod 2 and the top left side of the grip rod 1 are provided with a first groove 3, and the bottom of the first groove 3 below is connected to the top of the first groove 3 above. The first spring 4, the L-shaped frame 5 that can clamp nails is installed on the bottom end of the swing rod 2, the left side of the L-shaped frame 5 has a card slot 6, the sleeve 7 is installed on the left end of the grip bar 1, and the sleeve 7 is on the right The side is open, and the sleeve 7 cooperates with the L-shaped frame 5. There is a through groove 12 on the right side of the lower part of the sleeve 7, and an adjustment device 13 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com