A scrapped car dismantling line

A scrapped vehicle and assembly line technology, which is applied in the direction of vehicle scrapped recycling, motor vehicle, solid waste removal, etc., can solve the problems affecting the efficiency and safety of dismantling, pressing and processing difficult scrapped parts, time-consuming and laborious, etc. It is convenient to take and follow-up production, reduce the difficulty of work, and improve the effect of dismantling and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

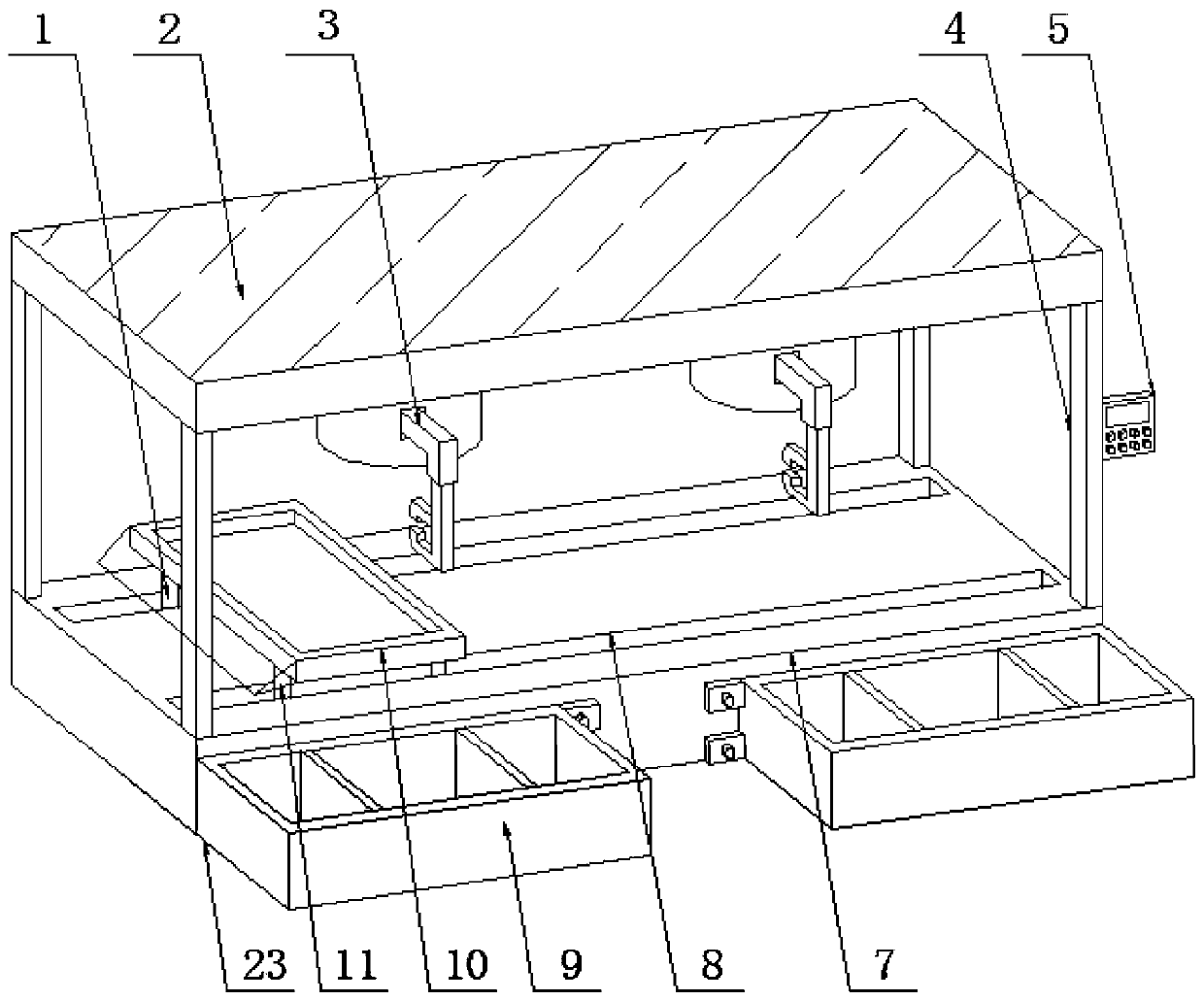

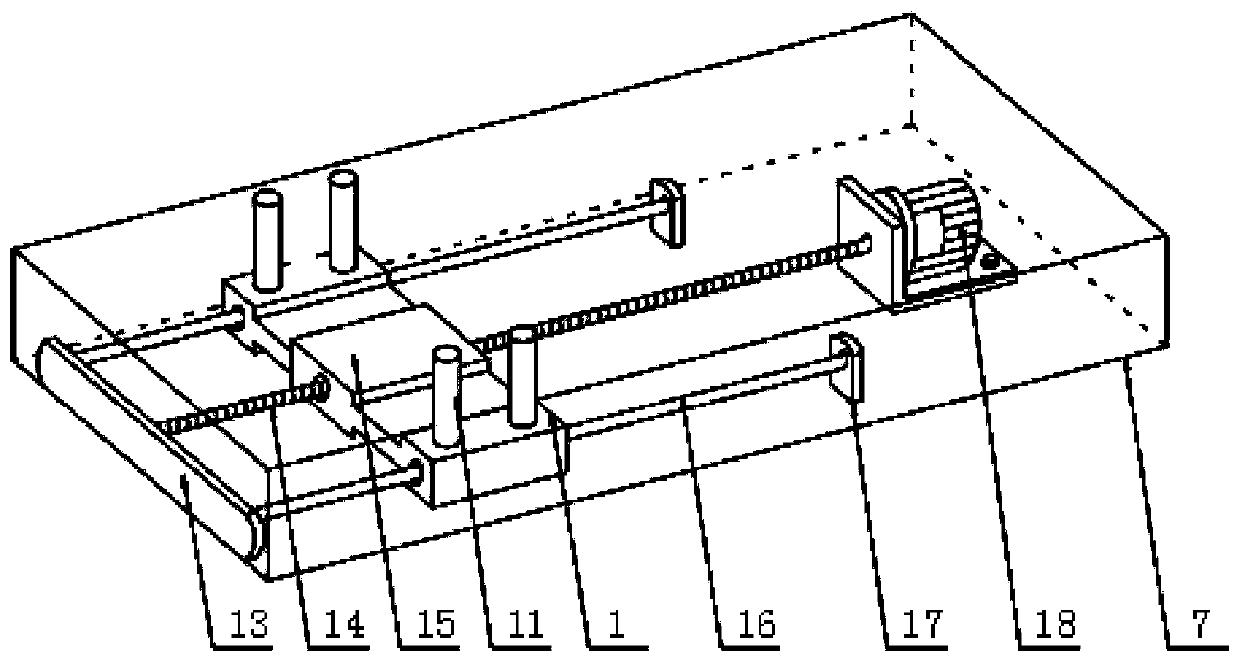

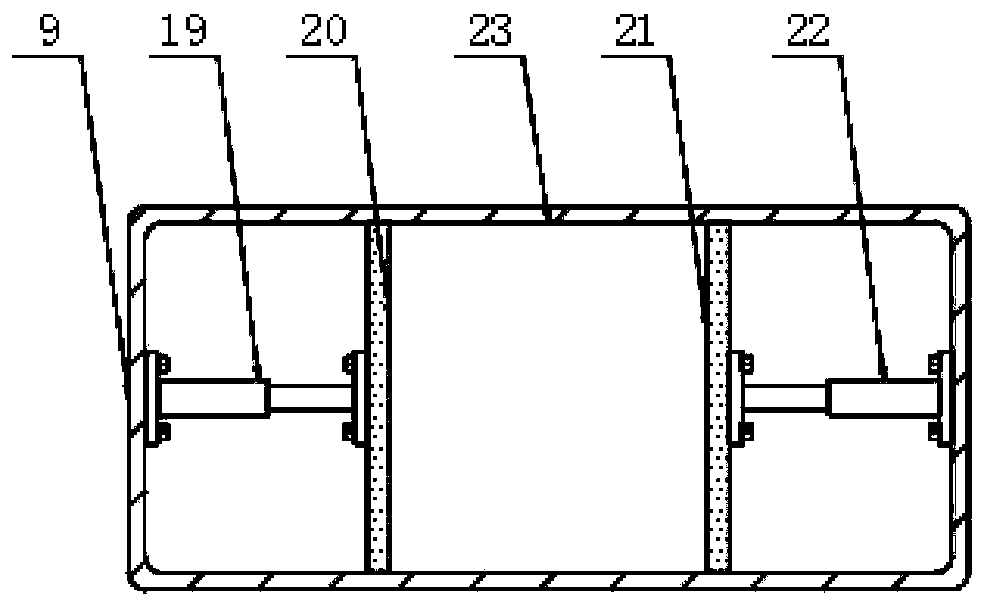

[0034] see Figure 1-7 , in an embodiment of the present invention, a scrapped automobile dismantling line, including a pretreatment station 01, a sheet metal dismantling station 02, and a powertrain dismantling station 03, which are arranged in sequence, wherein the pretreatment The top of the station is provided with a flushing pan 00 and an oil suction pan, wherein the flushing pan 00 is provided with a flushing head 05; the oil suction pan is provided with a suction nozzle, and the flushing head can wrap around Central vertical axis rotation;

[0035] One side of the sheet metal dismantling station 02 is provided with a flattening assembly for crushing and recycling the disassembled automobile sheet metal parts and a sheet metal manipulator 3 for clamping the automobile sheet metal parts; The power assembly dismantling station 03 is provided with a recovery box for recovering the dismantled power assembly parts, the recovery box is set on one side of the power assembly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com