Building formwork easy to dismount

A technology that is easy to disassemble and formwork is applied in construction, building construction, formwork/formwork/work frame, etc. It can solve the problems of poor grasp of the direction of force, difficulty in formwork maintenance, and damage to the side ribs of the formwork, etc. problem, to achieve the effect of simple and practical structure, saving storage space, easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

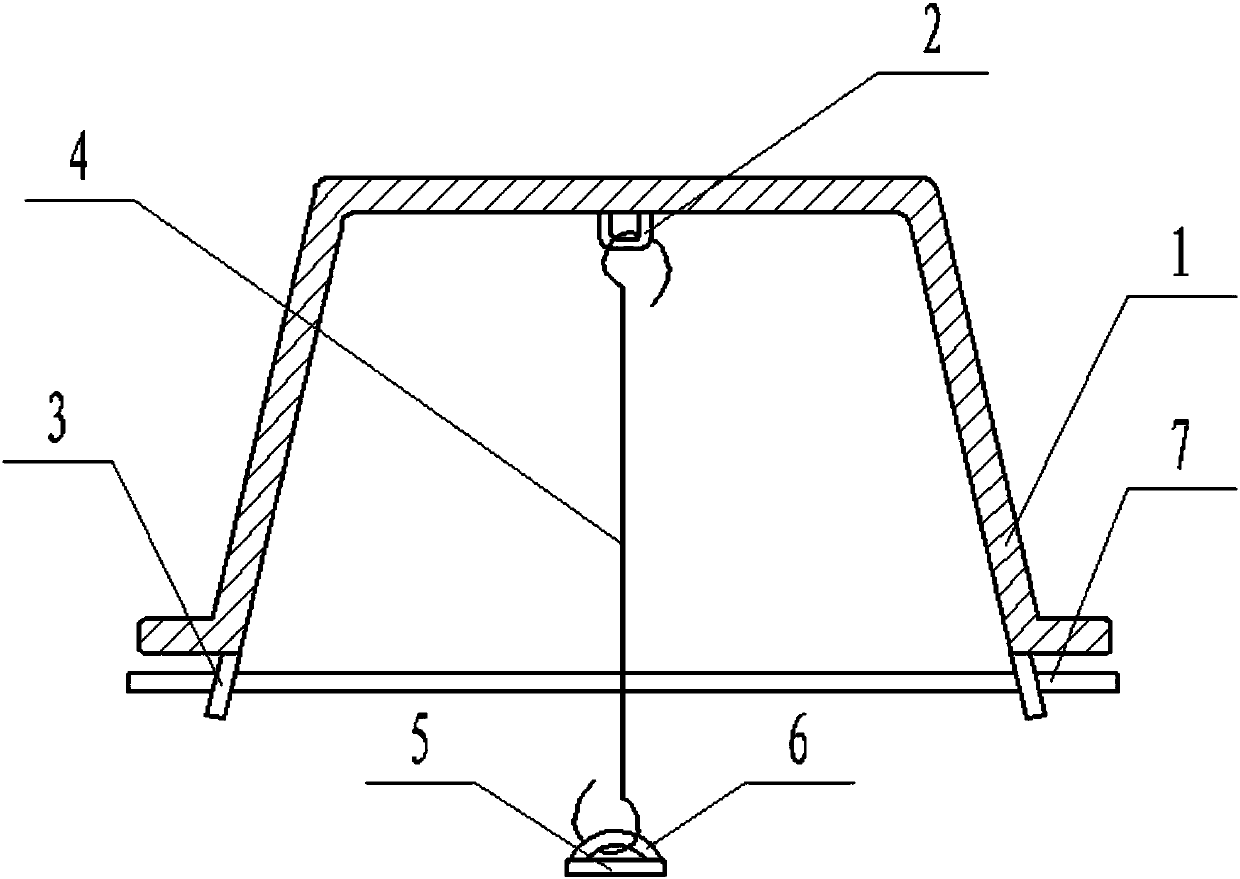

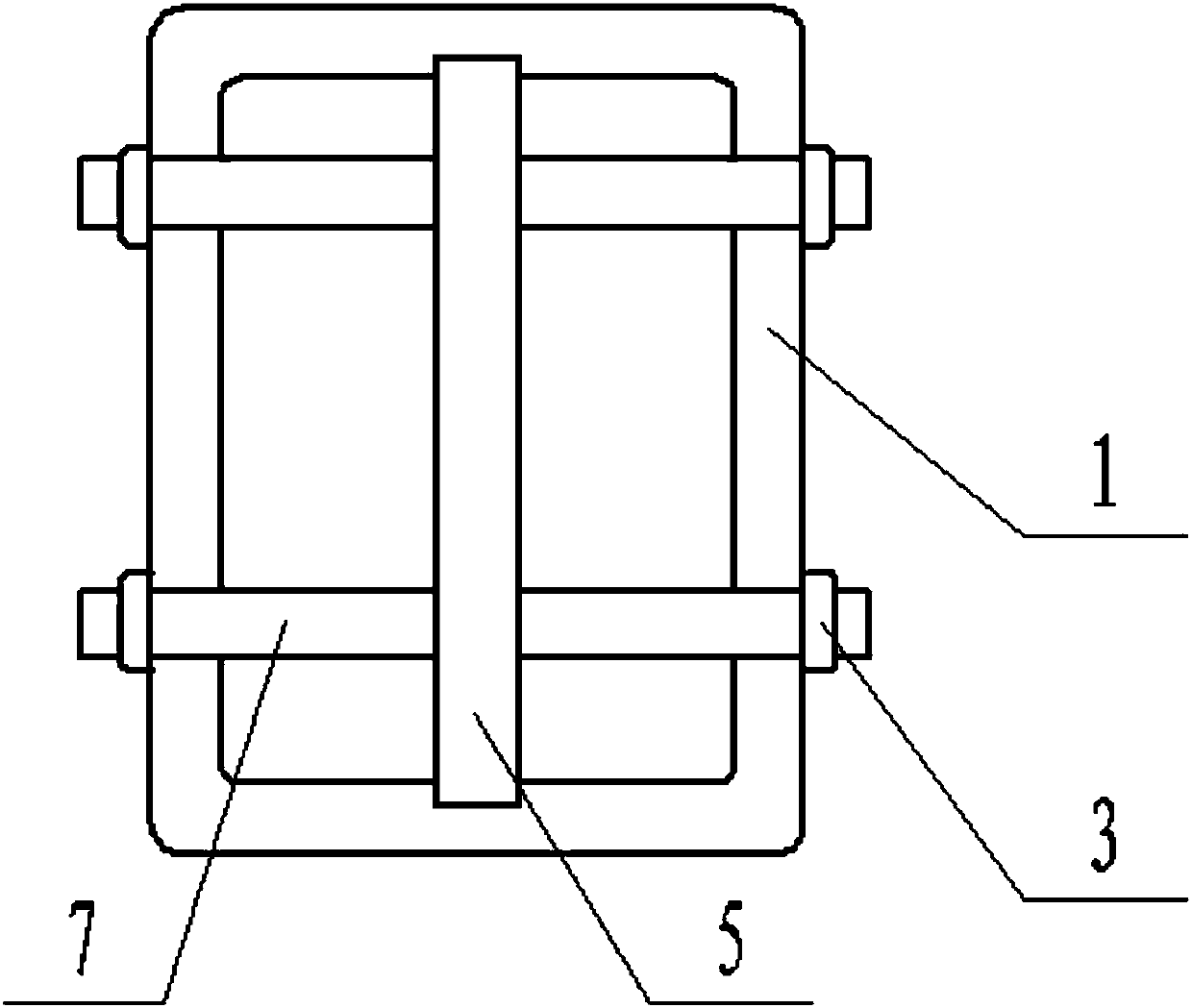

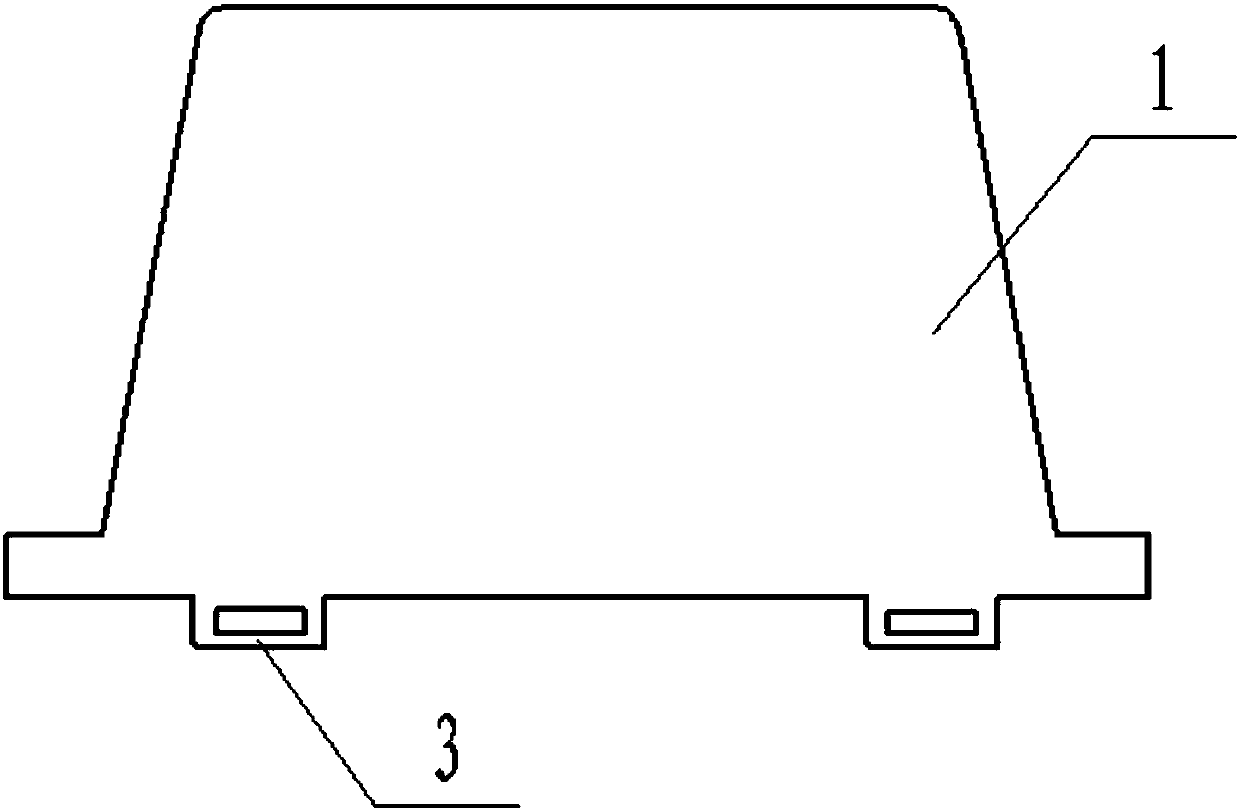

[0016] An easily disassembled building formwork, comprising a formwork main body 1, a shell top hanging ring 2, a shell side hanging ring 3, a hook 4, a stressed long plate 5, a stressed plate hanging ring 6, a stressed short plate 7, and a shell side The hanging ring 3 is arranged on the longer two sides of the formwork main body 1, the shell side hanging ring 3 is in contact with the stressed short plate 7, the shell top hanging ring 2 is arranged on the inner top surface of the formwork main body 1, and the shell top hanging ring 2 The hook 4 is connected with the force-bearing plate hanging ring 6, and the force-bearing plate hanging ring 6 is arranged at both ends of the force-bearing long plate 5 . The inner surface of the shell side hanging ring 3 is coplanar with the inner surface of the formwork main body 1 . The overall length of the hook 4 is greater than the height of the formwork main body 1 .

Embodiment 2

[0018] When the present invention is demoulding, one end of the hook 4 is hooked on the shell top hanging ring 2, the other end is hooked on the stressed plate hanging ring 6 at one end of the stressed long plate 5, and the stressed plate hanging ring 6 at the other end of the stressed long plate 5 Hook one end of the second hook 4, hook the other end of the second hook 4 to the second shell top hanging ring 2, insert the stressed short plate 7 into the opposite set of shell side hanging rings 3, and the second The short force plate 7 is inserted into the second set of opposite shell-side hanging rings 3, the long force plate 5 is perpendicular to the two short force plates 7, and the long force plate 5 is located at the lower end of the short force plate 7, and the worker beats it with a tool The stressed long plate 5, the stressed short plate 7, and the formwork main body 1 are successfully demolded under the combined force. After one formwork is demoulded, the force plate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com