Plug in rotary connection

A technology of rotating connection and plug, applied in the direction of connection, connecting device parts, contact parts, etc., can solve the problems of the plug falling off, the plug and the socket not being fully combined, and affecting the user's daily office.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

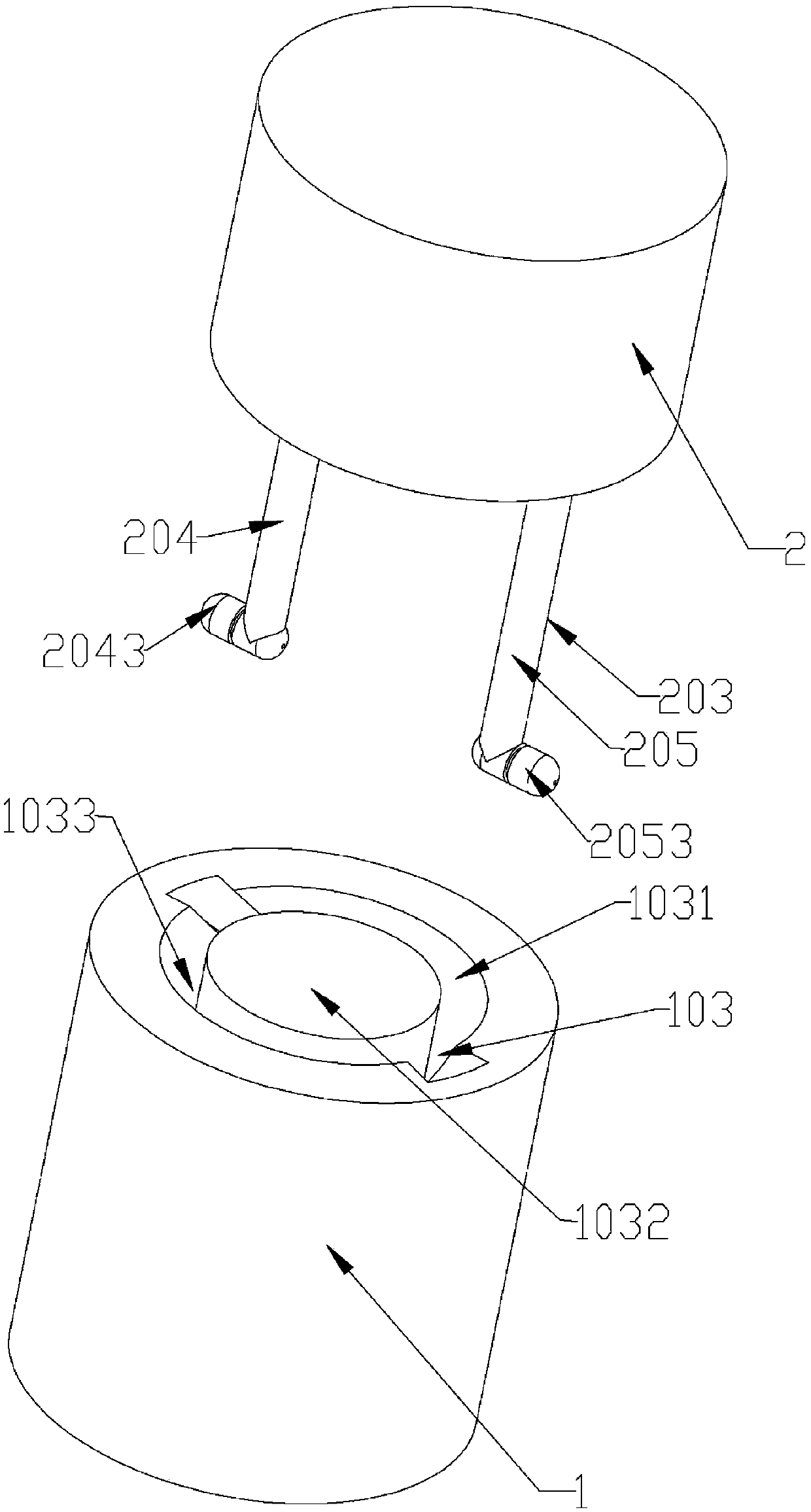

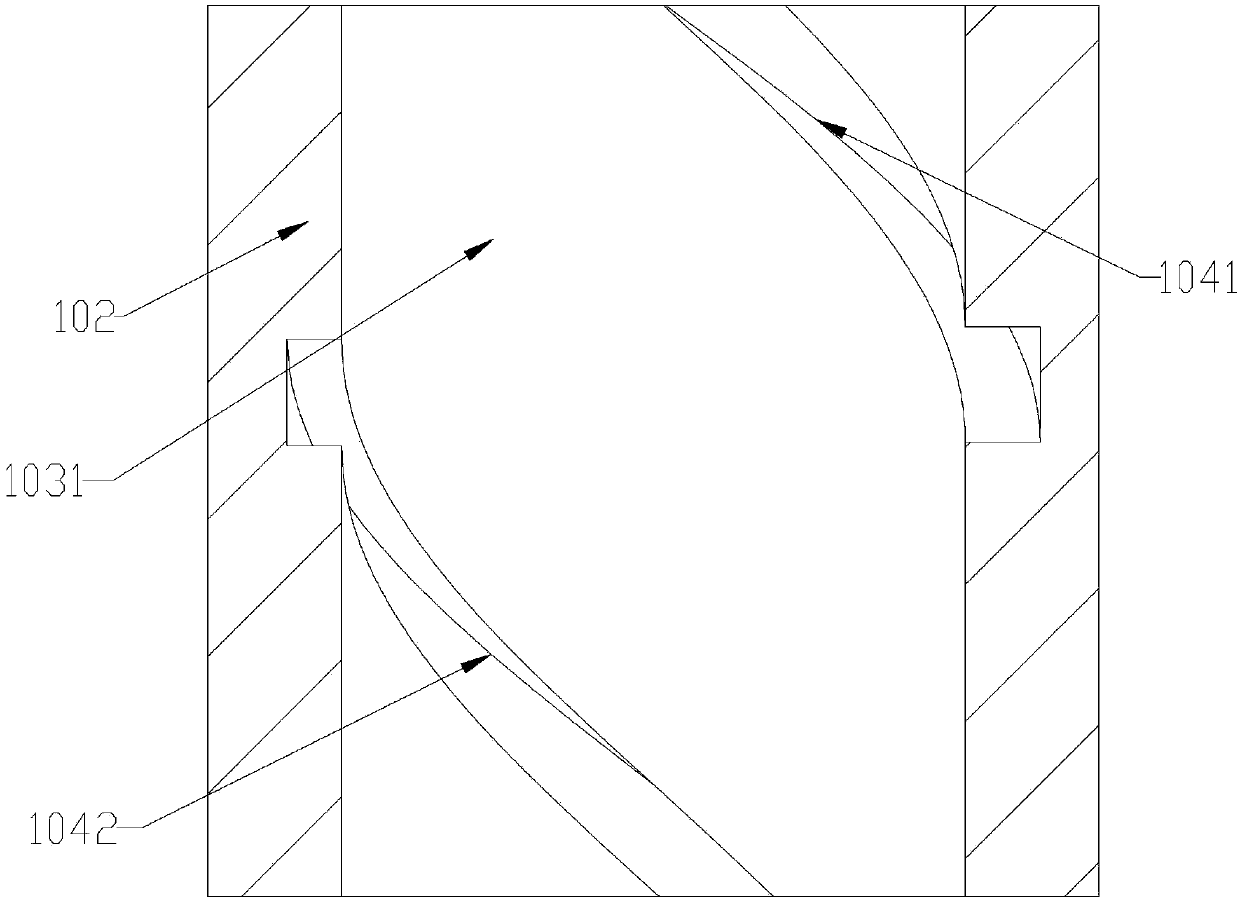

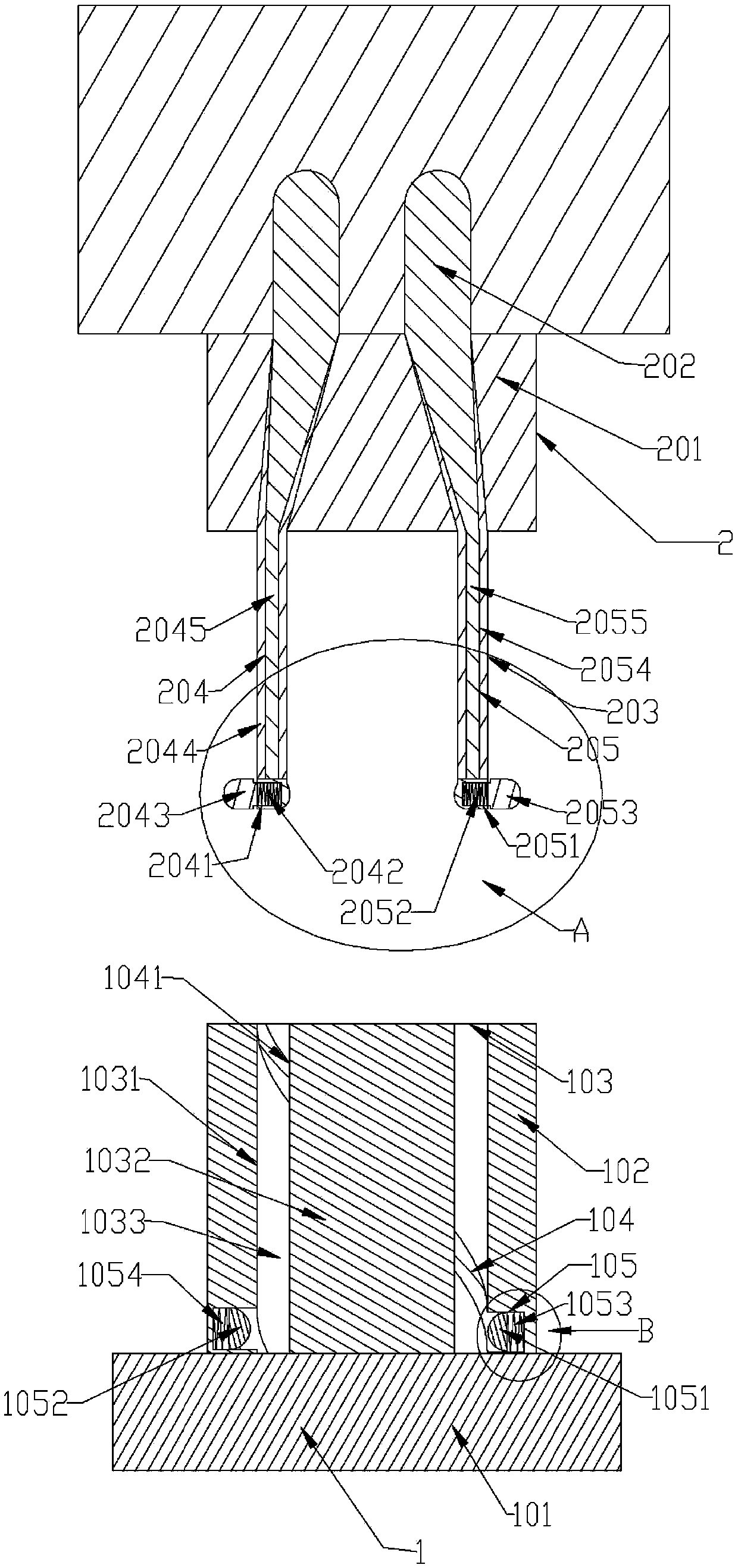

[0020] Example 1: see figure 1 , figure 2 , image 3 In the rotary socket set in this technical solution, after the plug-in part of the plug is inserted into the socket on one end of the outer side wall of the cylindrical socket, the plug needs to be rotated so that the plug-in part on the plug is on the inner edge of the socket The threaded groove structure slides in the thread direction. When the lower end of the plug-in part rotates to the lower end of the threaded groove structure, the lower end of the threaded groove structure will clamp the lower end of the plug-in part through a clamping structure; this technical solution The plug-in part in the middle includes a positive conductive tube and a negative conductive tube. The positive conductive tube includes a first insulating tube and a positive conductive sheet embedded in the first insulating tube. The negative conductive tube includes a second insulating tube and is embedded in the first insulating tube. The design of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com