Winding film pre-tightening and automatic film taking-up device of winding packaging machine

A technology of stretch film and film device, which is applied in the field of packaging, can solve problems affecting the quality of wrapping packaging, and achieve the effect of improving the quality of wrapping packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

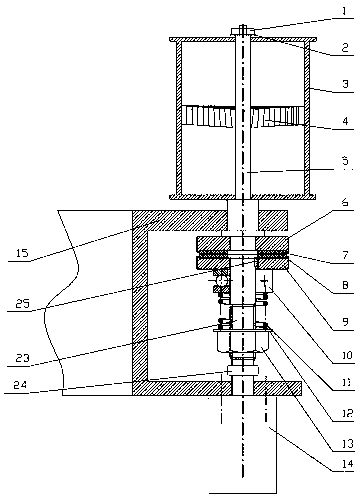

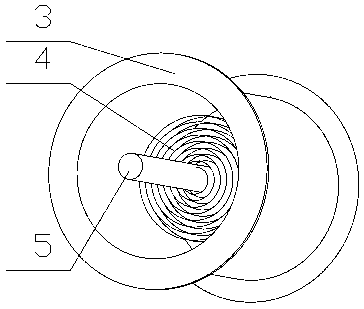

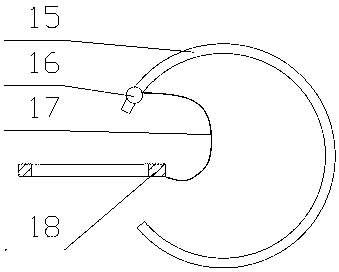

[0014] like figure 1 — Figure 5 , when the ring-shaped package 18 is vertically positioned and clamped by the ring-shaped package vertical positioning clamping device 20, the ring-shaped package 18 is positioned on the drive shaft of the incomplete gear positioning clamping ring mechanism of the ring-shaped package vertical positioning clamping device 20 Under the action of friction, the principle and process of circular low-speed rotation, vertical positioning clamping and circular low-speed rotation can be found in another patent authorized by our research team. 201720000242x), at the same time, the C ring 15 drives the wrapping film 17 to pass through the ring package 18 to rotate and wrap it. Every time the C ring 15 rotates once, the ring package 18 rotates on the ring package vertical positioning clamping device 20 The arc length is about half of the film width of the stretch film 8, so as to ensure that the stretch film 17 can overlap layer by layer and wrap reliably....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com