Method for operating a chain drive and assembly having a chain drive

A technology of chain transmission and facilities, which is applied in the direction of transmission, transportation and packaging, mechanical equipment, etc., can solve problems such as inaccuracy, and achieve the effects of reducing wear, avoiding operational failures, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

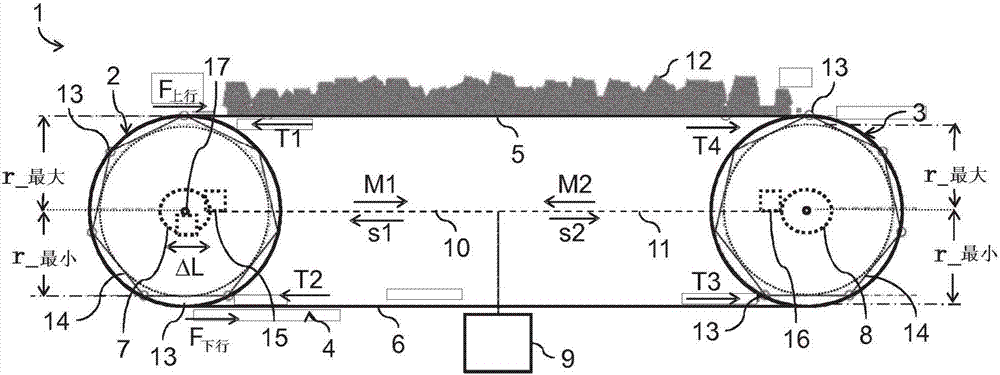

[0048] figure 1 A chain drive 1 is shown as an example in the form of a chain conveyor with two sprockets 2 , 3 and a conveyor belt 4 driven by them with an upper run 5 and a lower run 6 . The drive element 7 is arranged as main drive element on the sprocket 2 , schematically drawn on the left, in order to drive this sprocket. A further drive 8 is arranged as an auxiliary drive on the other sprocket 3 in order to drive the other sprocket.

[0049] The control device 9 serves to control the drives 7 , 8 . By way of example, the control device 9 is connected to the drives 7 , 8 via lines 10 , 11 , wherein other transmission systems, in particular, can also be used for the measurement and control signals. In particular, control signals s1 , s2 for actuating the drives 7 , 8 can be transmitted from the control device 9 to the drives 7 , 8 . The conveyor belt 4 , which can be driven by means of the drives 7 , 8 , is used for transporting the conveyed material 12 , for example pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com