Gear drive type garbage bag side-edge sealing device

A sealing device and gear transmission technology, applied in the field of gear transmission type garbage bag side sealing device, can solve the problems of inability to pull, high production cost, long sealing time, etc., and achieve stable and reliable force, low production cost, and sealing short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

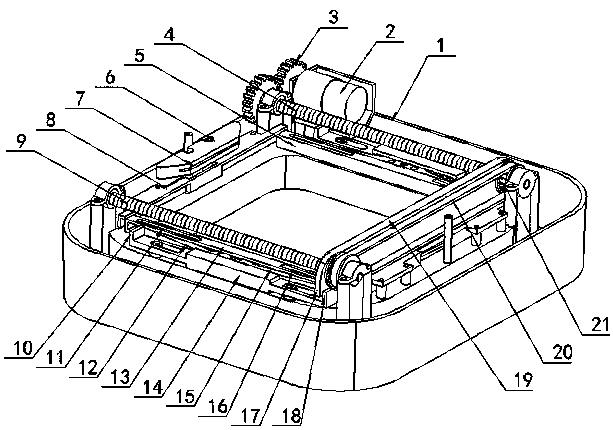

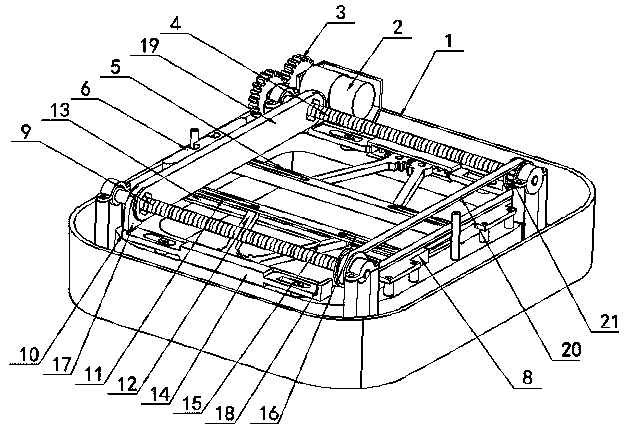

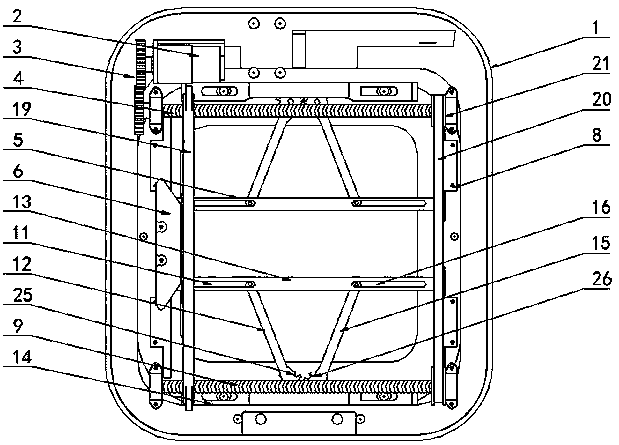

[0018] Figure 1 to Figure 4 As shown, the present invention creates a specific embodiment of a gear-driven garbage bag side sealing device, which is installed on the bucket cover 1 and is located below the garbage delivery port 23 of the bucket cover 1. The bucket cover 1 is provided with Place the garbage bag annular storage tank 22 of the pull-out garbage bag, and the garbage bag stretches in the garbage can from the garbage delivery port 23. The sealing device includes a driving mechanism, a draw-in clamping mechanism, and a hot-melt mechanism, and the described hot-melt mechanism is fixed in the middle of the front side of the garbage delivery port 23, and the described draw-in clamping mechanism includes left and right screw rods 9, 4, pressing plates 19, left and right Depression rod 13,5, front and rear push rod 12,15, rack moving rod 14, left and right screw rods 9,4 can rotate synchronously and be arranged on the both sides of garbage delivery port 23, and the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com