Patents

Literature

53results about How to "Stable and reliable force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

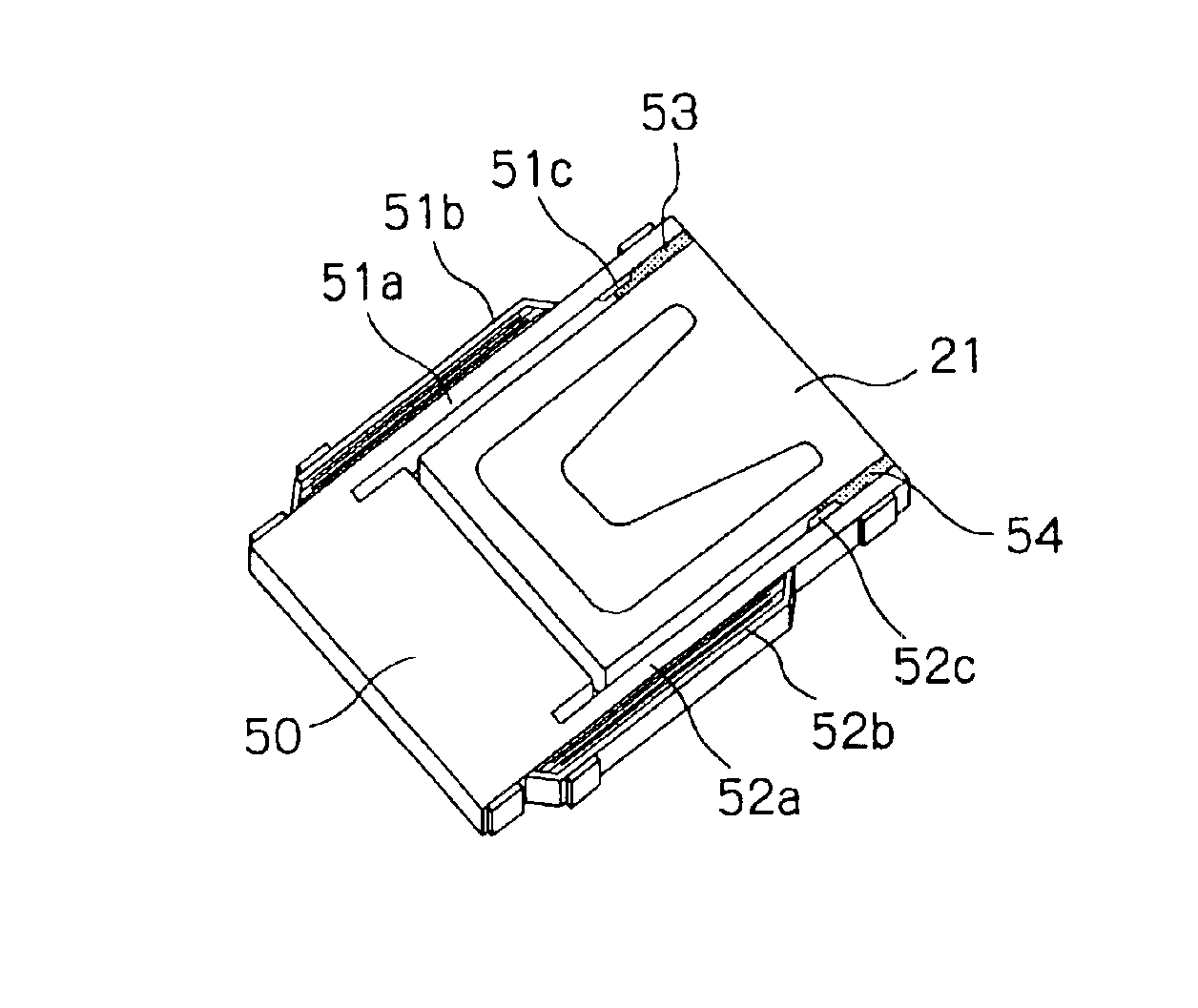

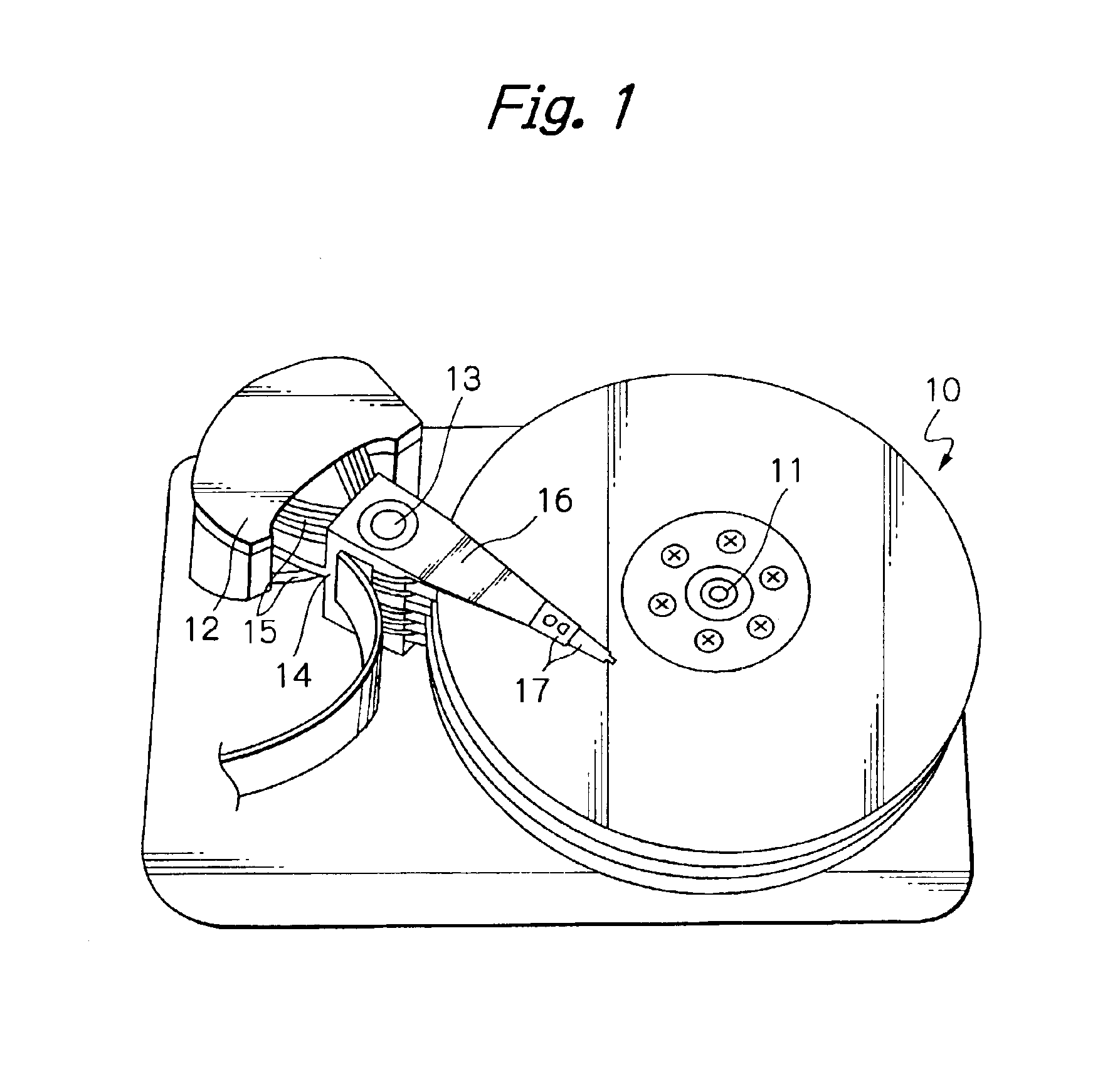

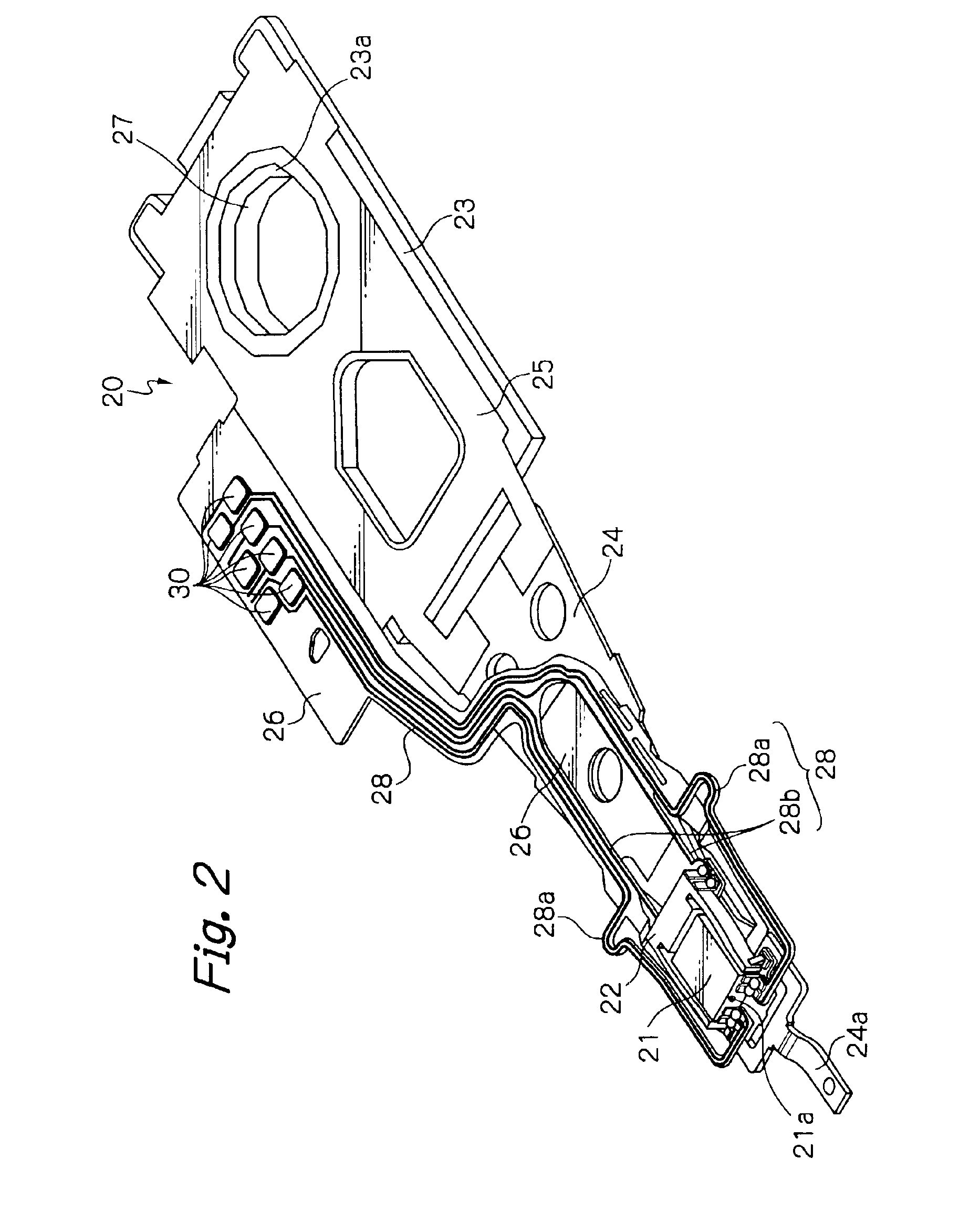

Precise positioning actuator for head element, head gimbal assembly with the actuator and disk drive apparatus with the head gimbal assembly

InactiveUS6934127B2Improve seismic performanceStable and reliable adhesionTrack finding/aligningRecord information storageEngineeringActuator

A precise positioning actuator for precisely positioning at least one head element is provided with a base and a pair of movable arms capable of displacing in response to a drive signal applied to the actuator. The pair of movable arms extend from the base for catching a head slider with at least one head element in a space between the pair of movable arms. Each of the pair of movable arms includes an arm member made of an elastic sintered ceramic and having substantially the same cross sectional shape from a root thereof to a top end thereof, a piezoelectric element formed on a side surface of the arm member and a protrusion additionally formed on an inside surface of the arm member near its top end section. The protrusion has tapered surfaces. Side surfaces of the head slider are adhered to the inside surfaces of the arm members at the protrusions and within regions between the protrusions and top ends of the arm members.

Owner:SAE MAGNETICS (HK) LTD

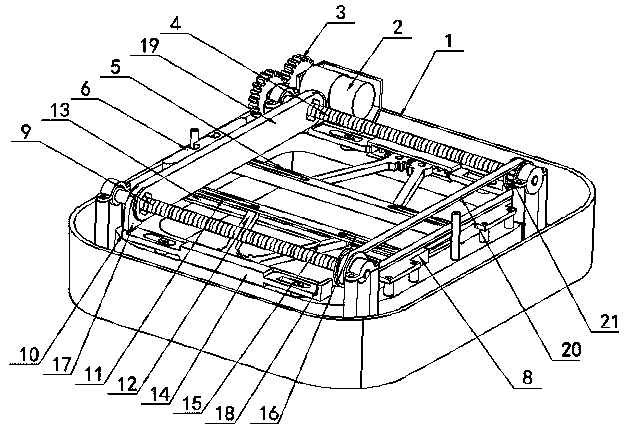

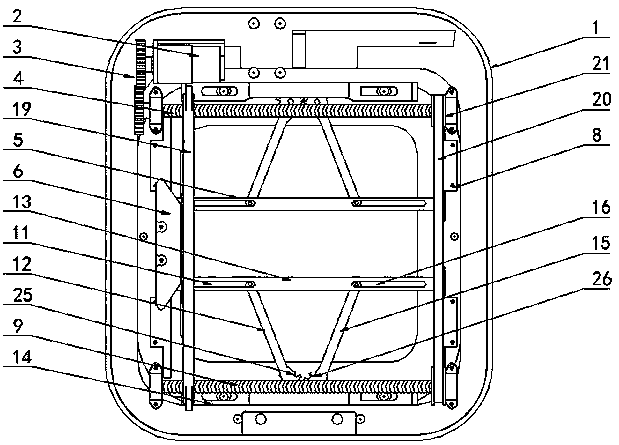

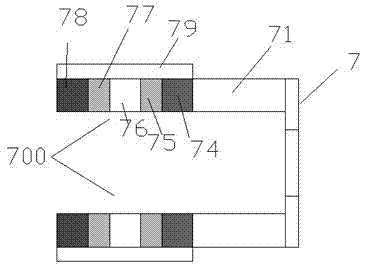

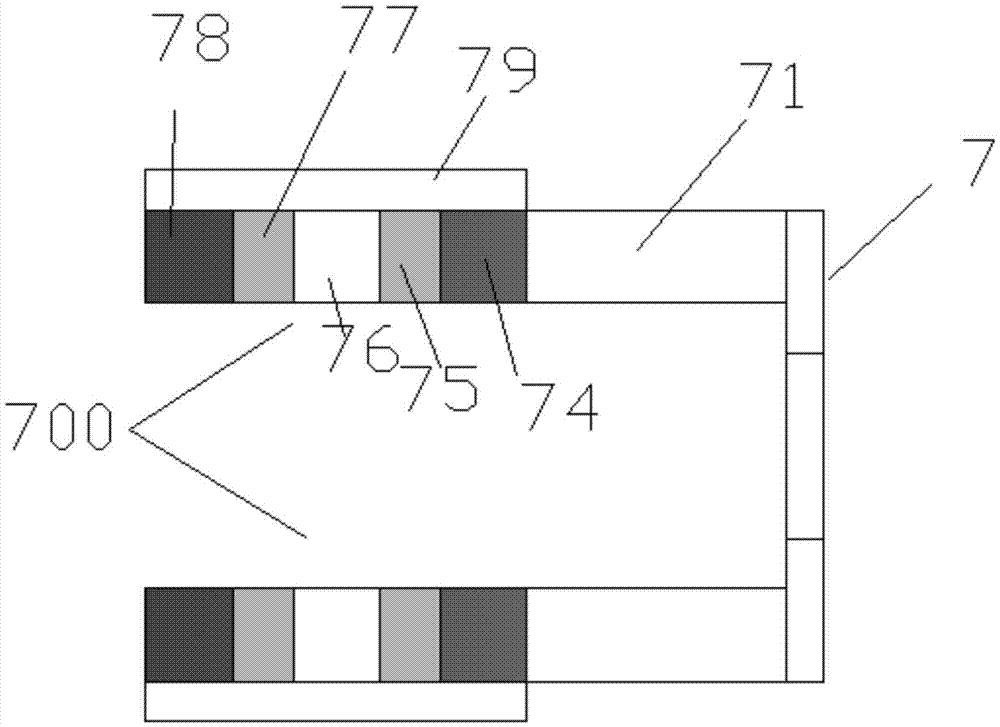

Gear drive type garbage bag side-edge sealing device

InactiveCN109573384AStable and reliable forceSolve the continuous meltingRefuse receptaclesEngineeringFast speed

The invention discloses a gear drive type garbage bag side-edge sealing device which comprises a drive mechanism, a converging and clamping mechanism and a hot melting mechanism. The converging and clamping mechanism comprises a left screw rod, a right screw rod, a pressing plate, a left pressing rod, a right pressing rod, a front push rod, a back push rod and rack moving rods; the left screw rodand the right screw rod are arranged on two sides of a garbage throwing port; the pressing plate is arranged on the left screw rod and the right screw rod; the rack moving rods are arranged on the left side and the right side of the garbage throwing port; the front push rod and the back push rod are arranged on the left side and the right side of the garbage throwing port through a drive gear anda driven gear meshing with each other; the other ends of the front push rod and the back push rod are slidably arranged on the left pressing rod and the right pressing rod; the drive gear meshes withstraight tooth grooves on the rack moving rods; and during work, the left screw rod and the right screw rod drives the pressing plate, the pressing plate drives the left pressing rod and the right pressing rod to push a garbage bag to converge and press tightly through the front push rod and the back push rod. By adopting the structure, the gear drive type garbage bag side-edge sealing device hasthe advantages of simple and reasonable structure, stability and reliability in converging and pressing the garbage bag, good sealing quality, fast speed and the like.

Owner:陈政

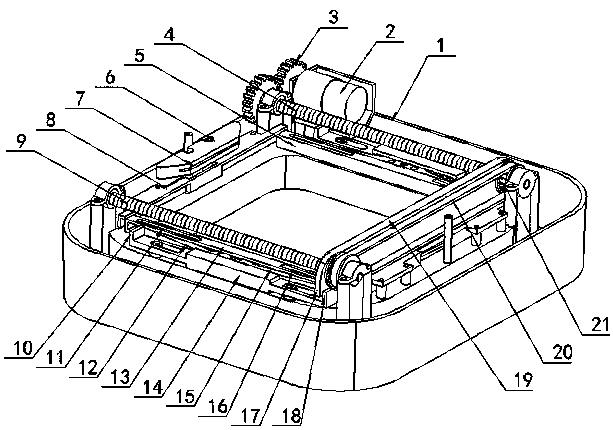

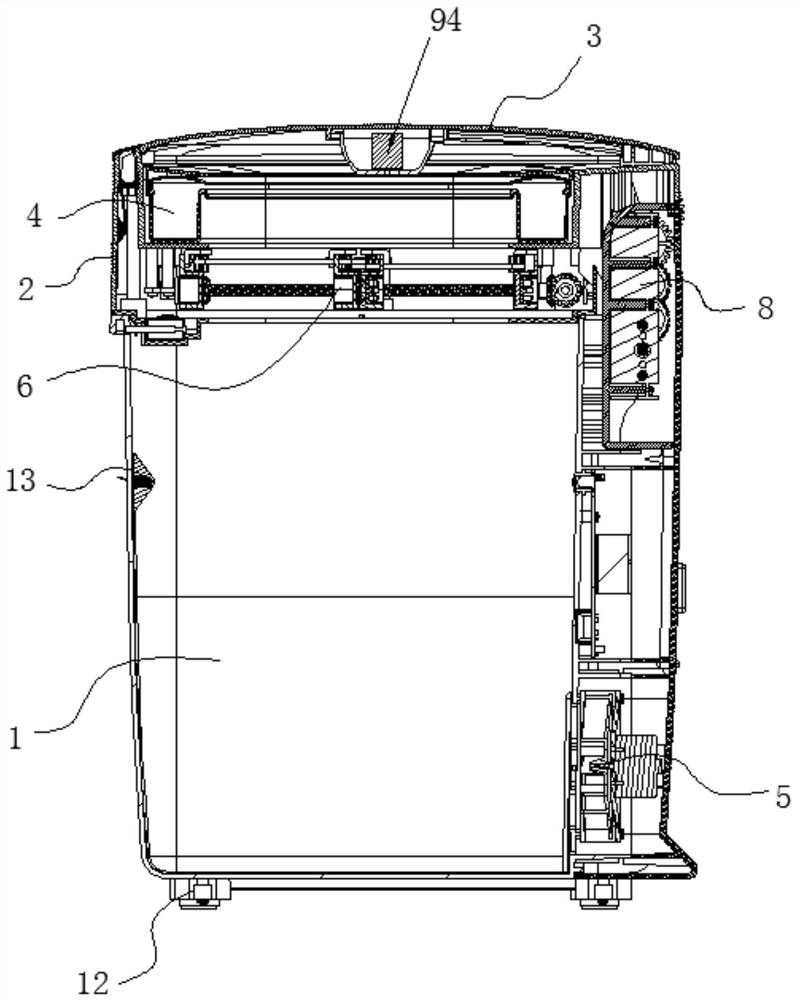

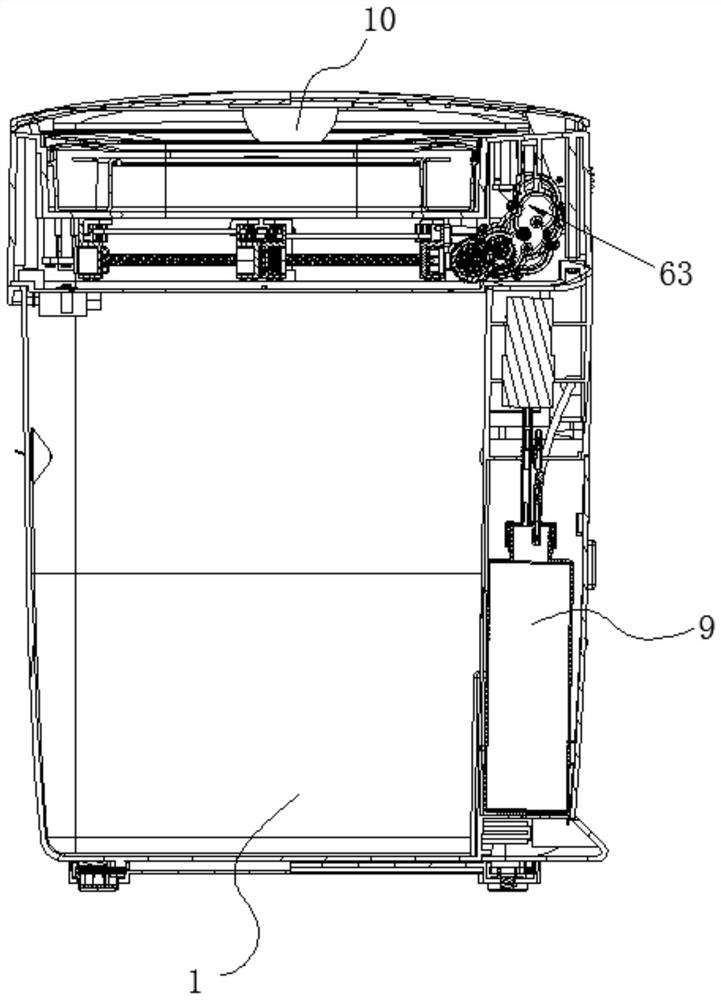

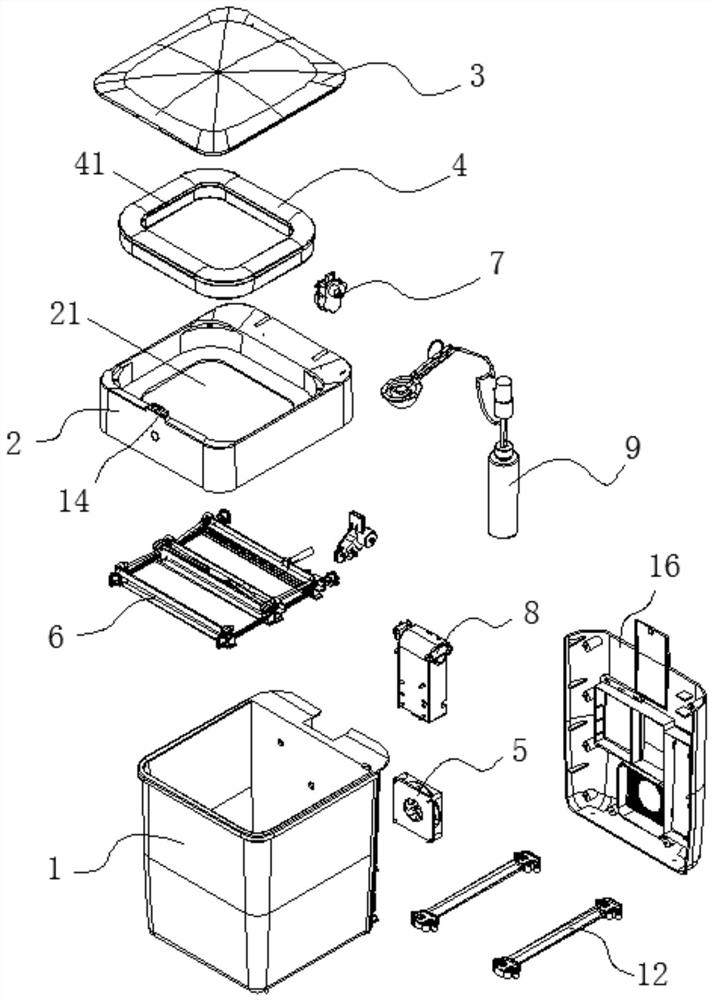

Novel automatic packaging intelligent garbage can

ActiveCN114194667AAchieve a well-proportioned finishEvenly around the doseWaste collection and transferRefuse receptaclesPlastic packagingEngineering

The novel automatic packaging intelligent garbage can comprises a can body, a middle cover, a top cover and a garbage bag box, an exhaust fan is arranged at the lower end of the can body, and an automatic closing thermal plastic sealing cutting mechanism is arranged in the middle cover; the automatic closing-up thermal plastic sealing cutting mechanism comprises a first lead screw, a second lead screw, a lead screw driving device, a folding rod set used for forcing a garbage bag opening to be folded inwards left and right, and a thermal plastic sealing bag cutting device used for conducting thermal plastic sealing on the garbage bag and cutting off the garbage bag. The cold pressing end device is used for being matched with the thermal plastic packaging bag cutting device to tightly press a garbage bag opening front and back, and the folding rod set comprises a first folding rod, a second folding rod, a third folding rod and a fourth folding rod. According to the garbage can, automatic packaging and sealing operation of the garbage bag can be achieved, the automatic closing-up thermal plastic sealing cutting mechanism is simple in structure, stable in sealing quality and high in speed, uniform closing-up of the garbage bag can be achieved, a uniform and flat packaging and sealing face is formed on the opening of the garbage bag, and the using amount of the periphery of the garbage bag is uniform.

Owner:邹志刚

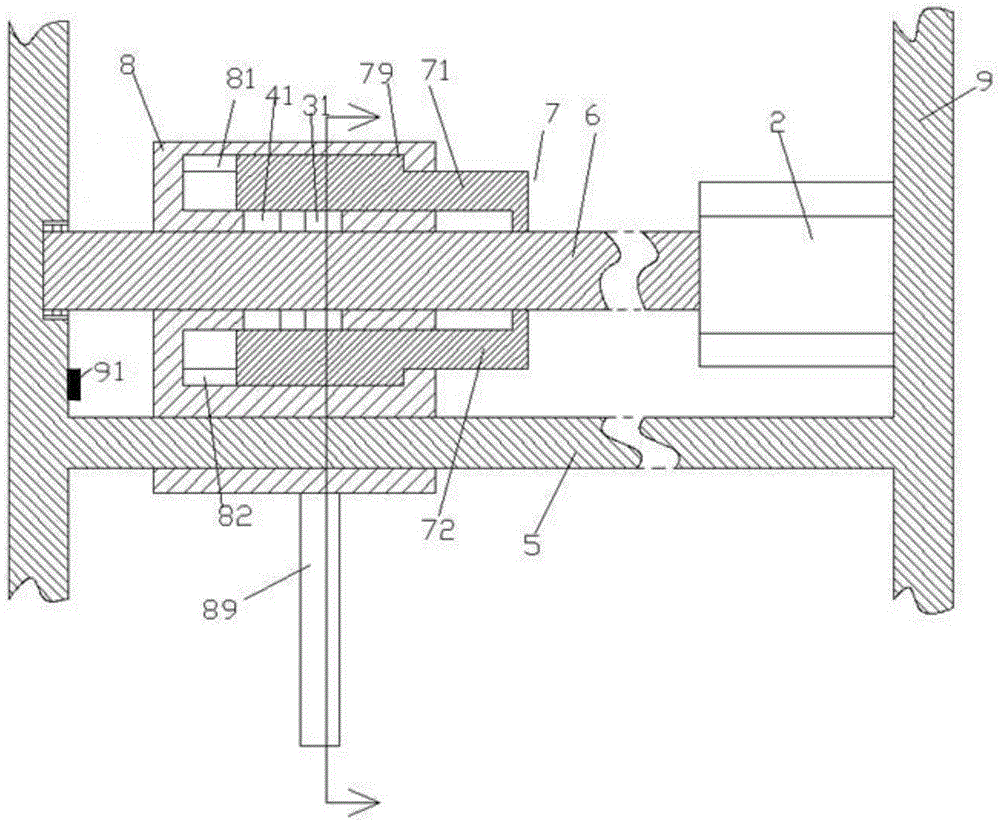

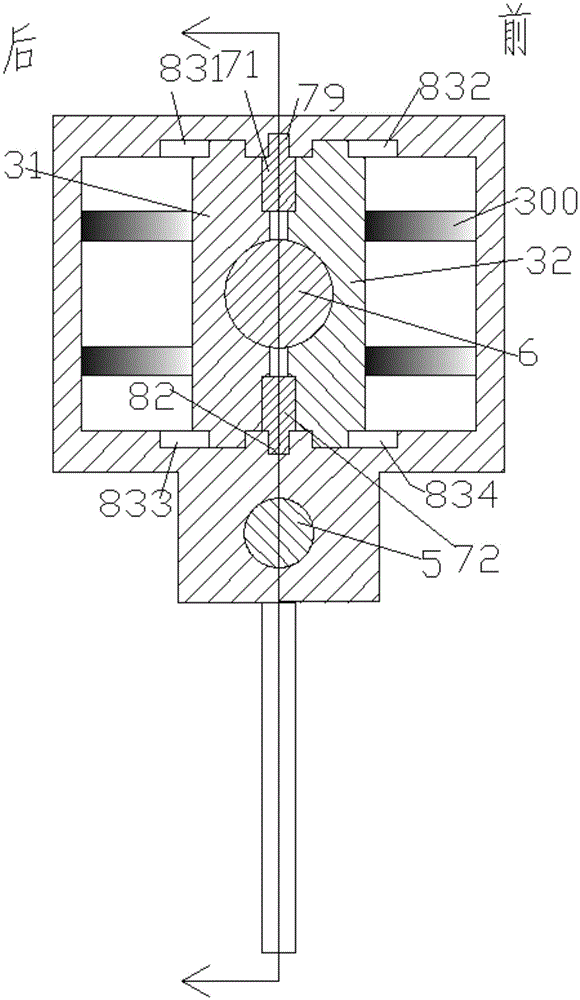

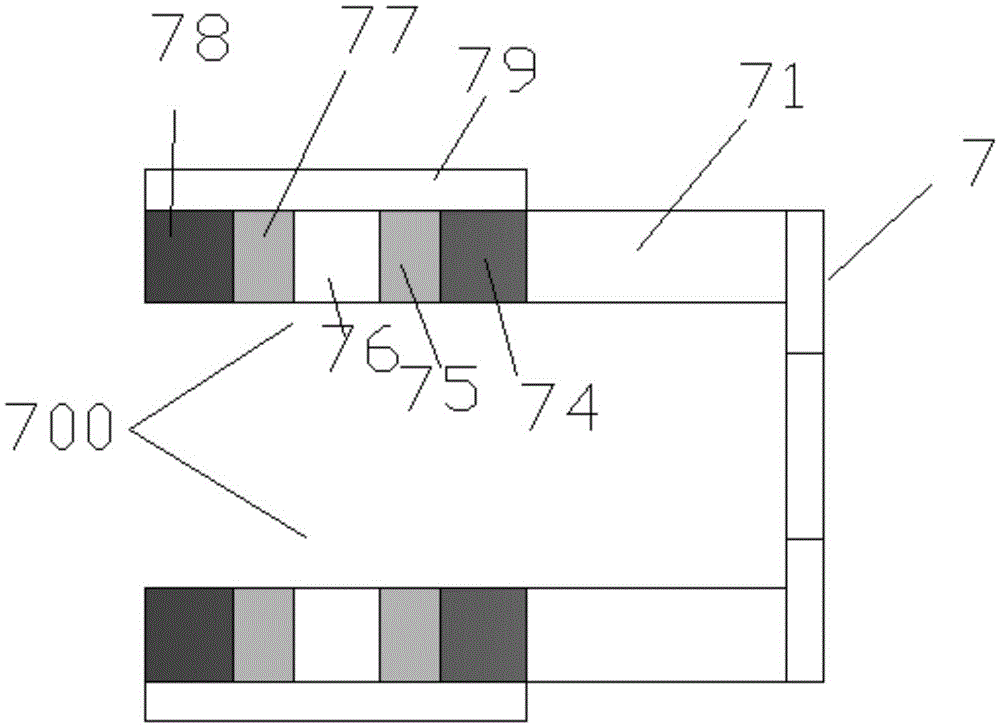

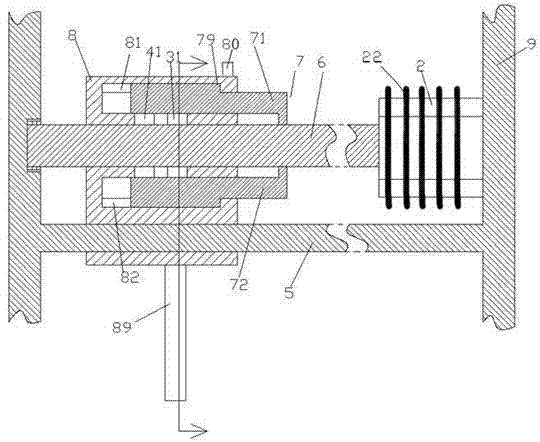

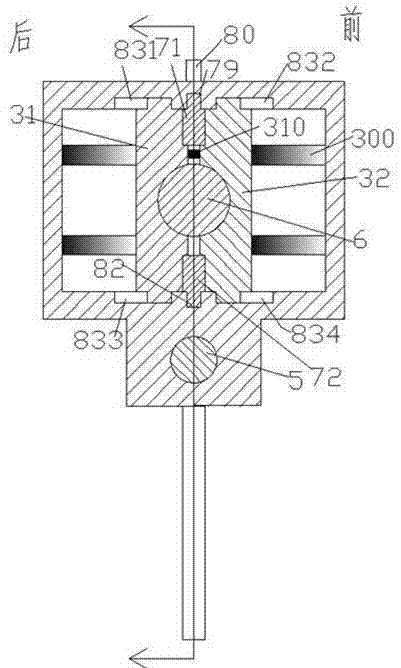

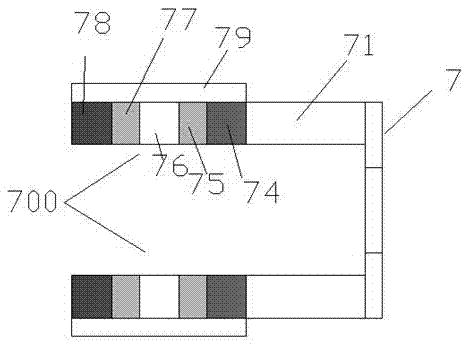

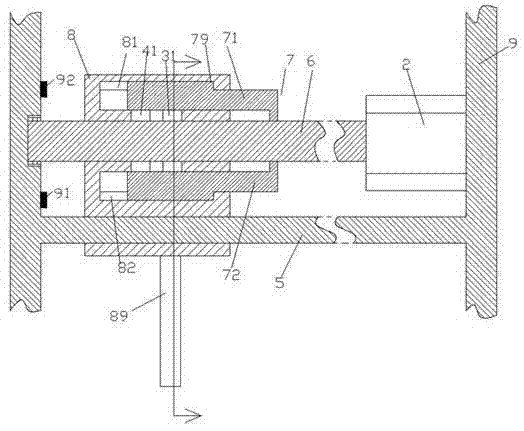

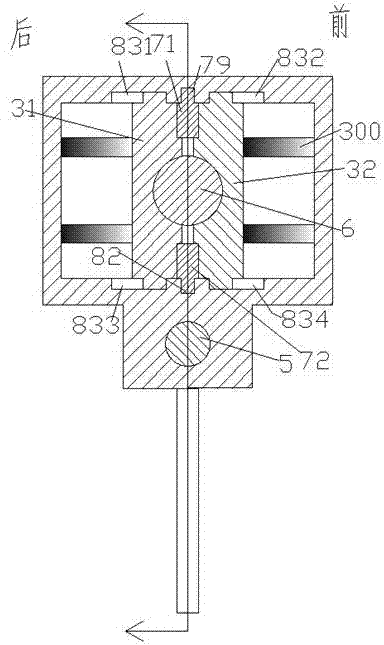

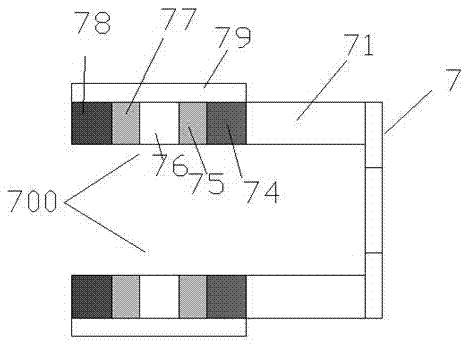

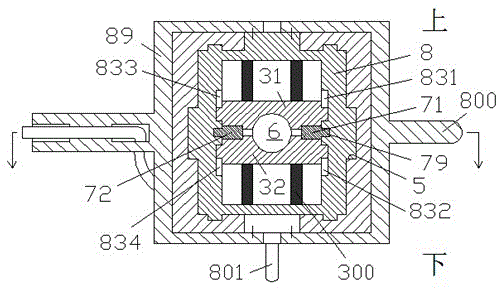

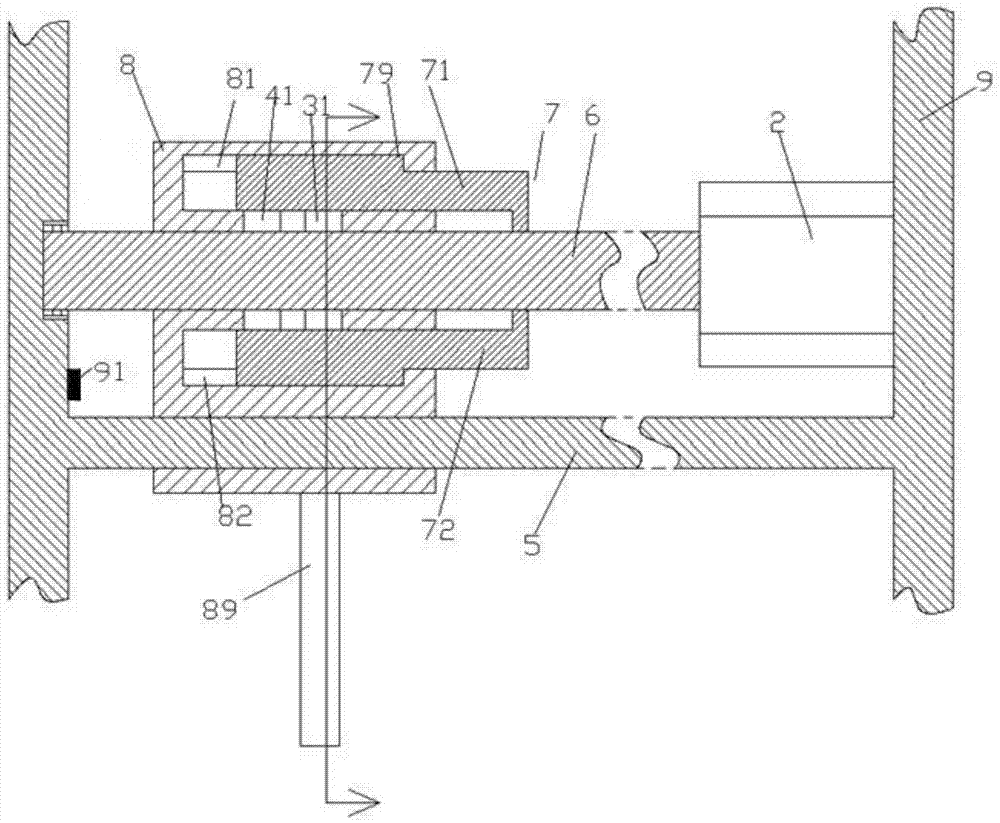

Limitable welding gun traveling mechanism for welding machine

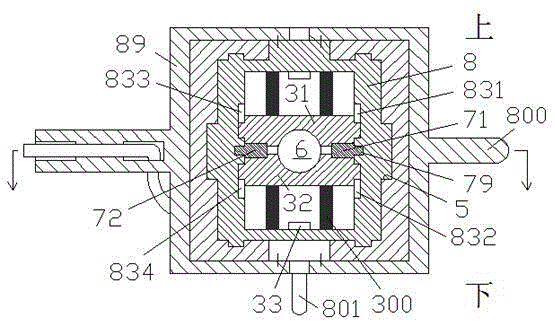

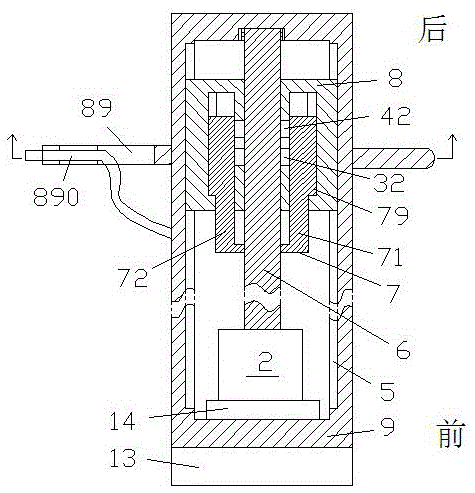

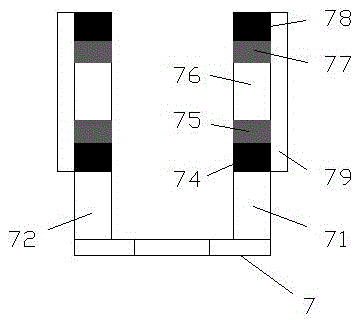

InactiveCN105414829AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesElastic componentThreaded rod

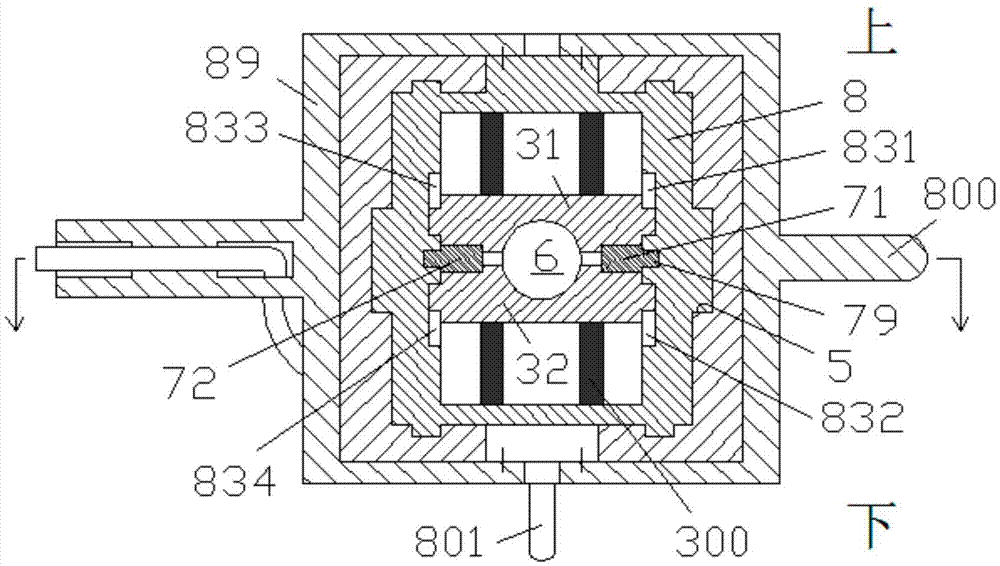

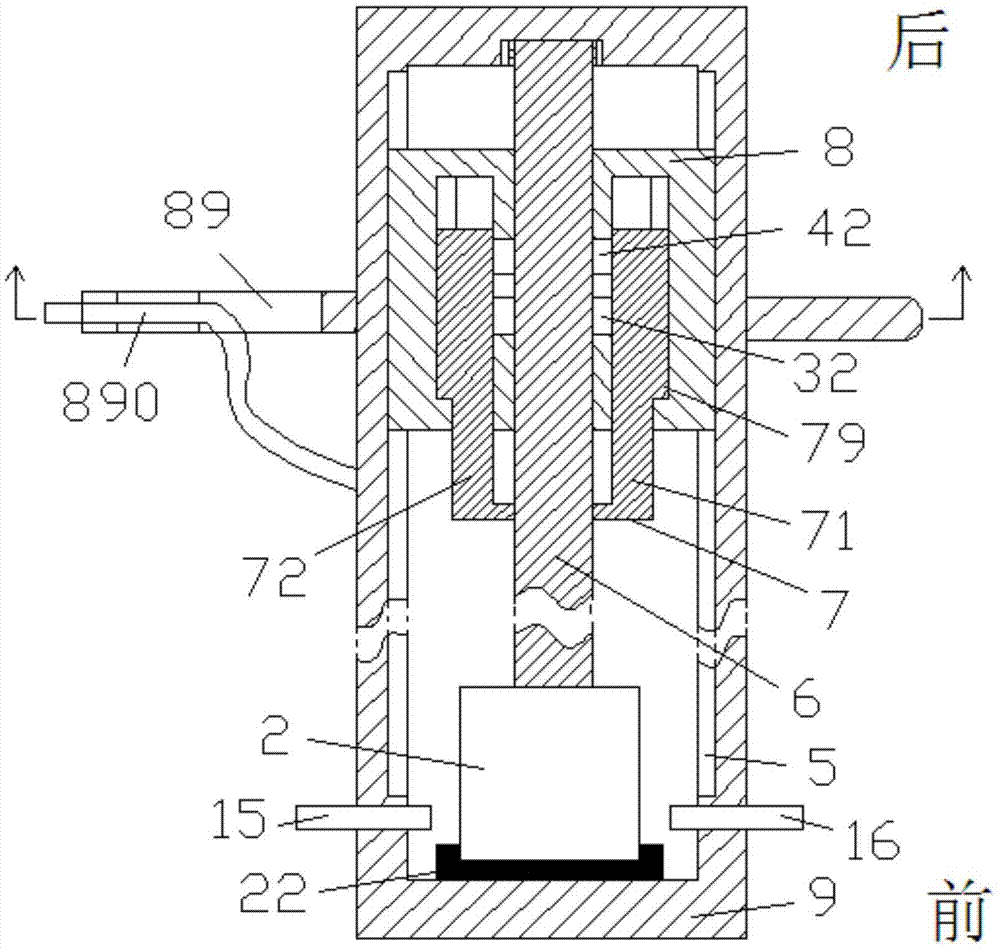

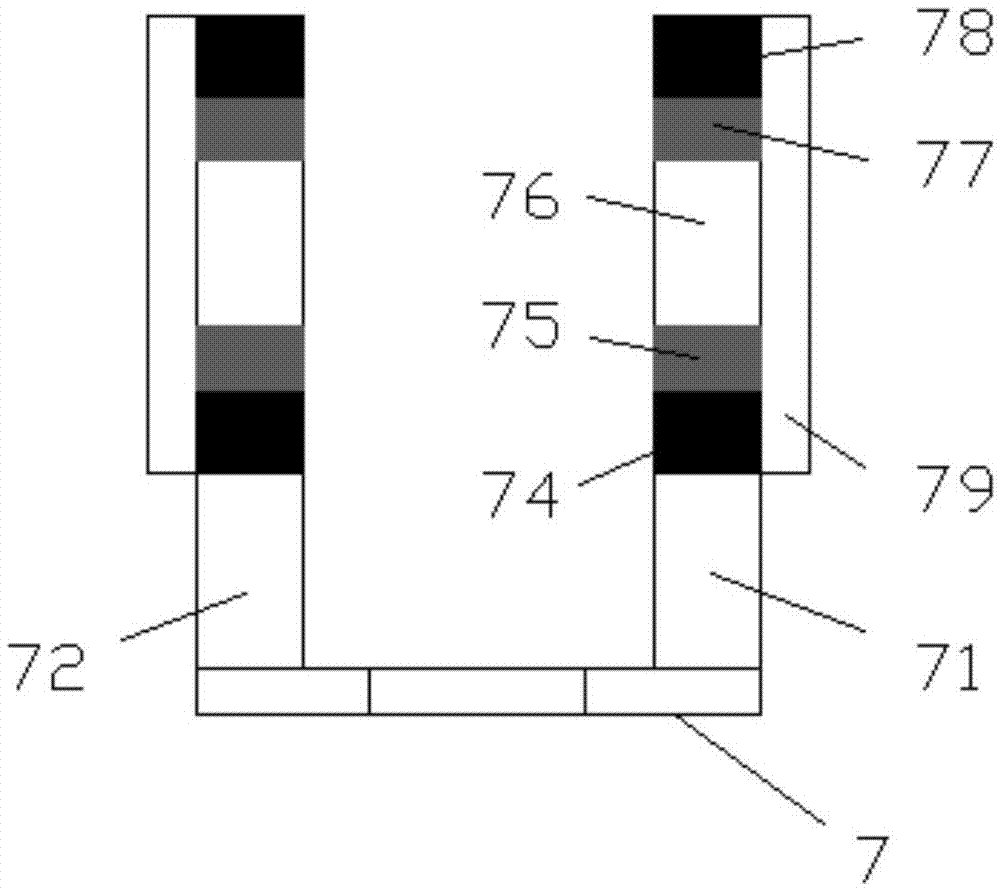

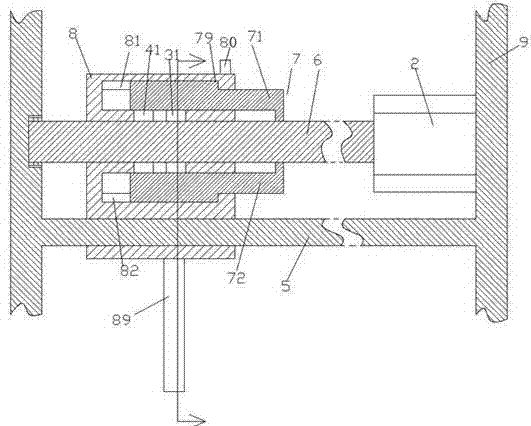

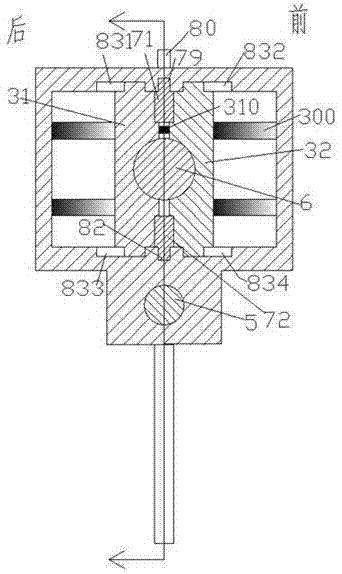

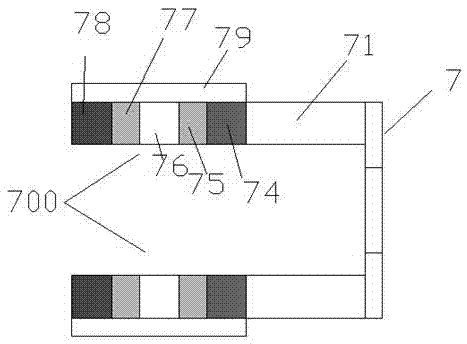

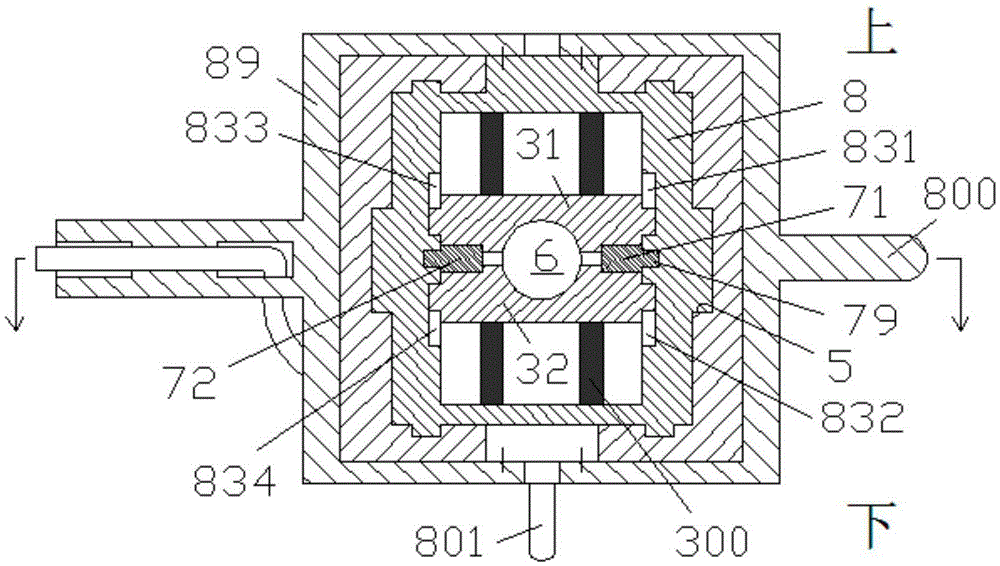

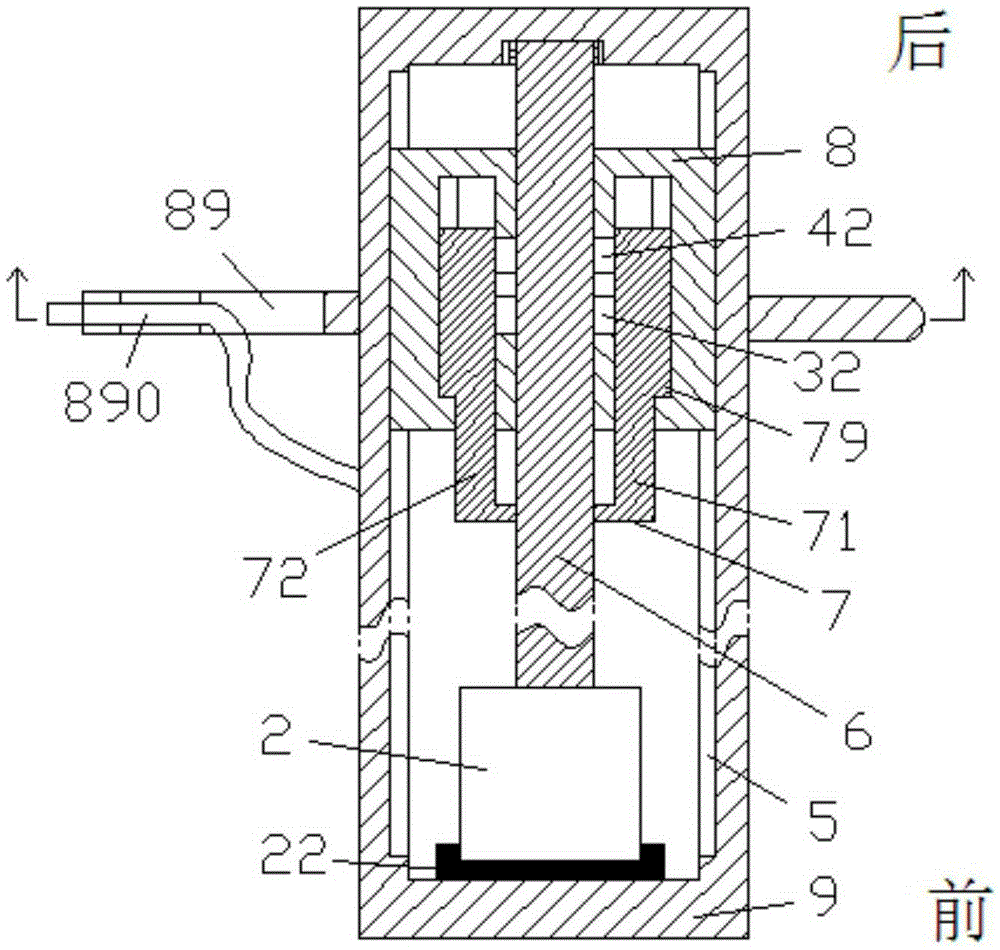

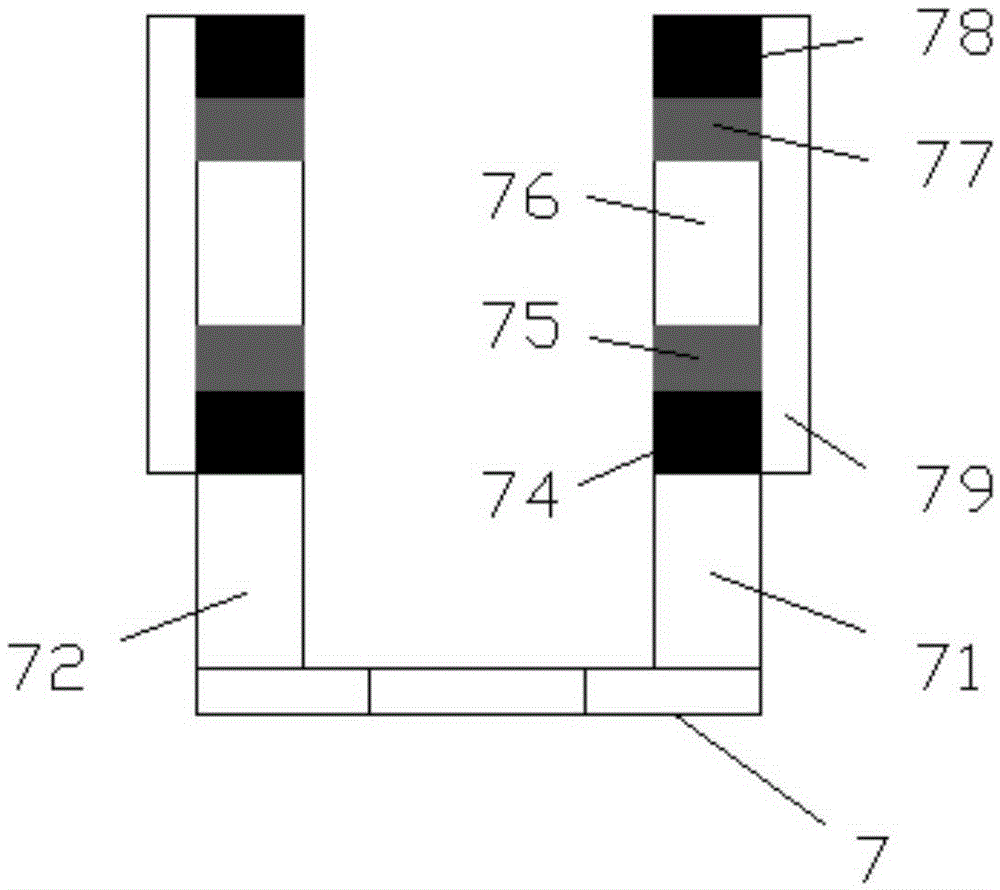

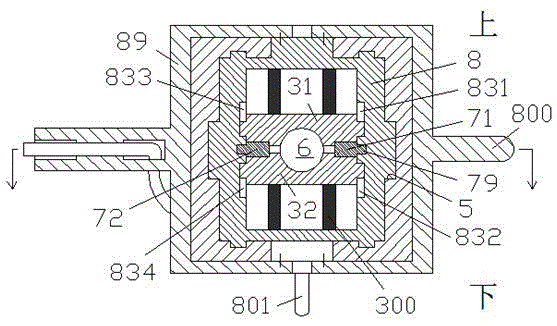

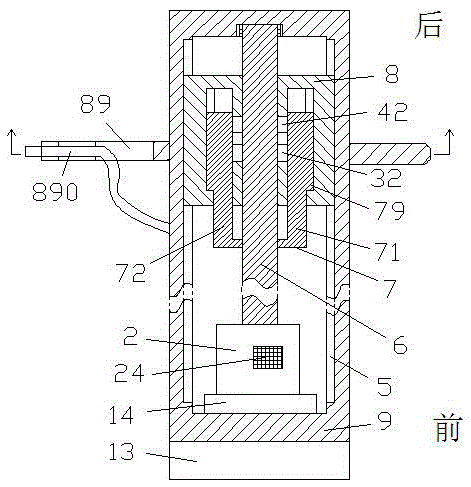

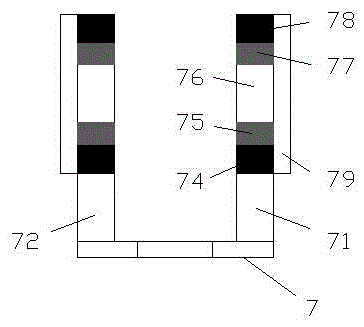

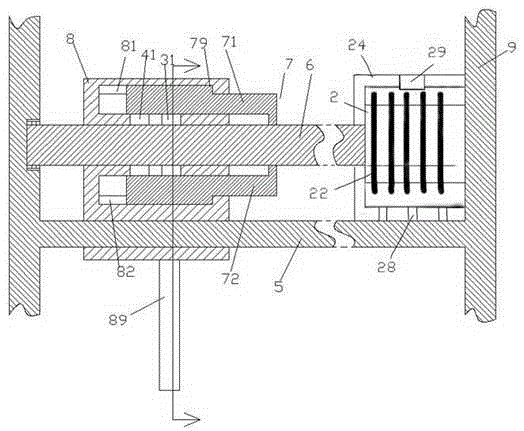

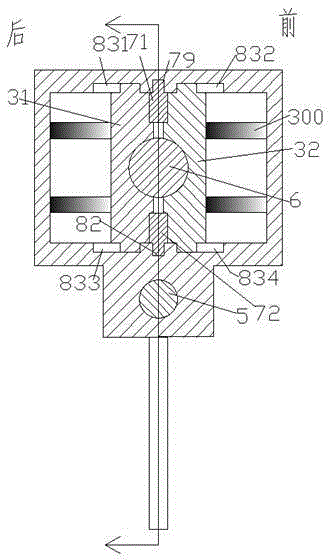

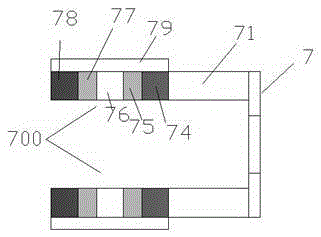

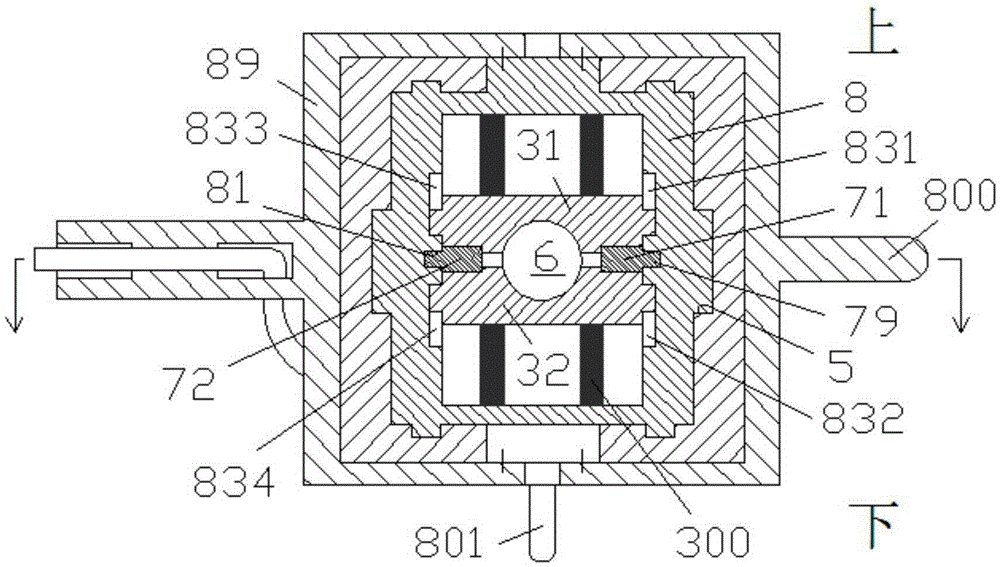

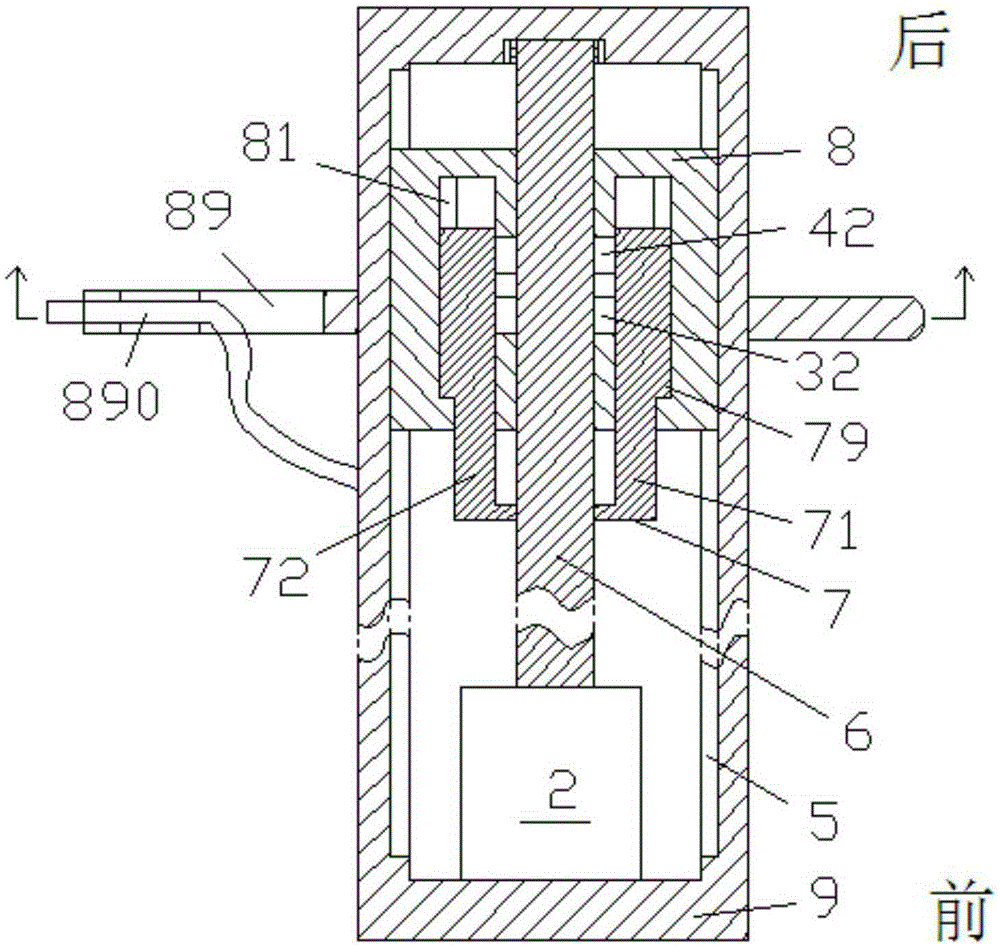

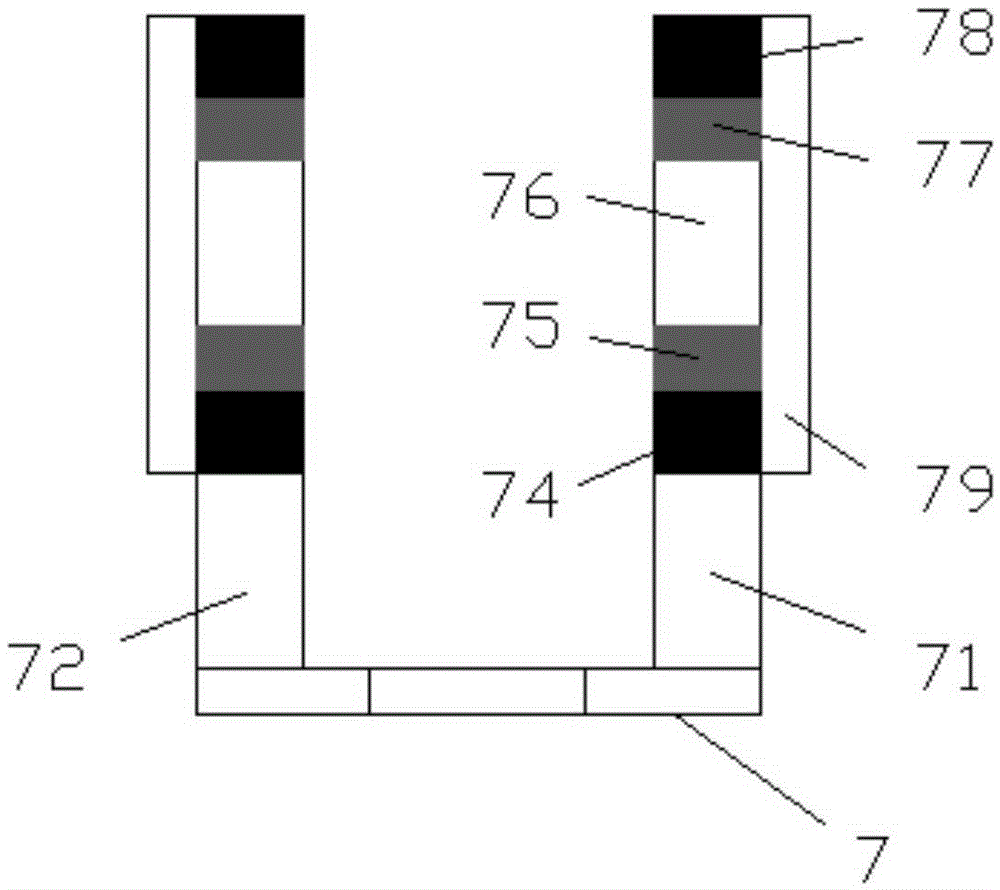

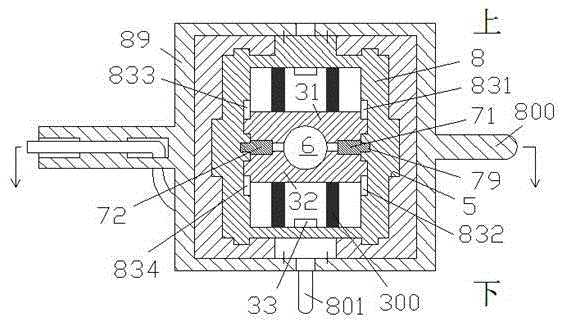

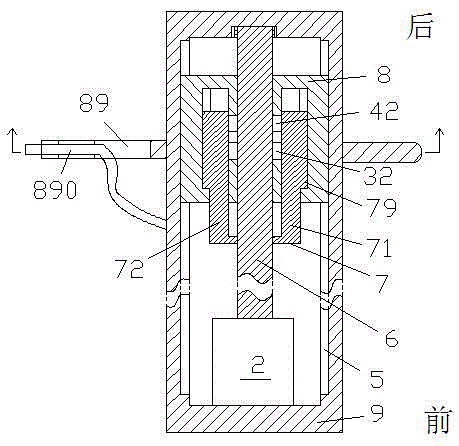

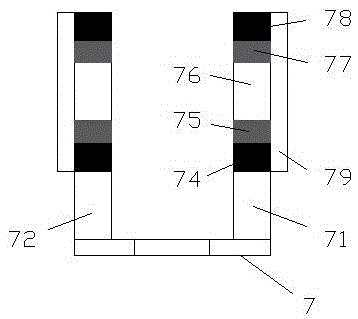

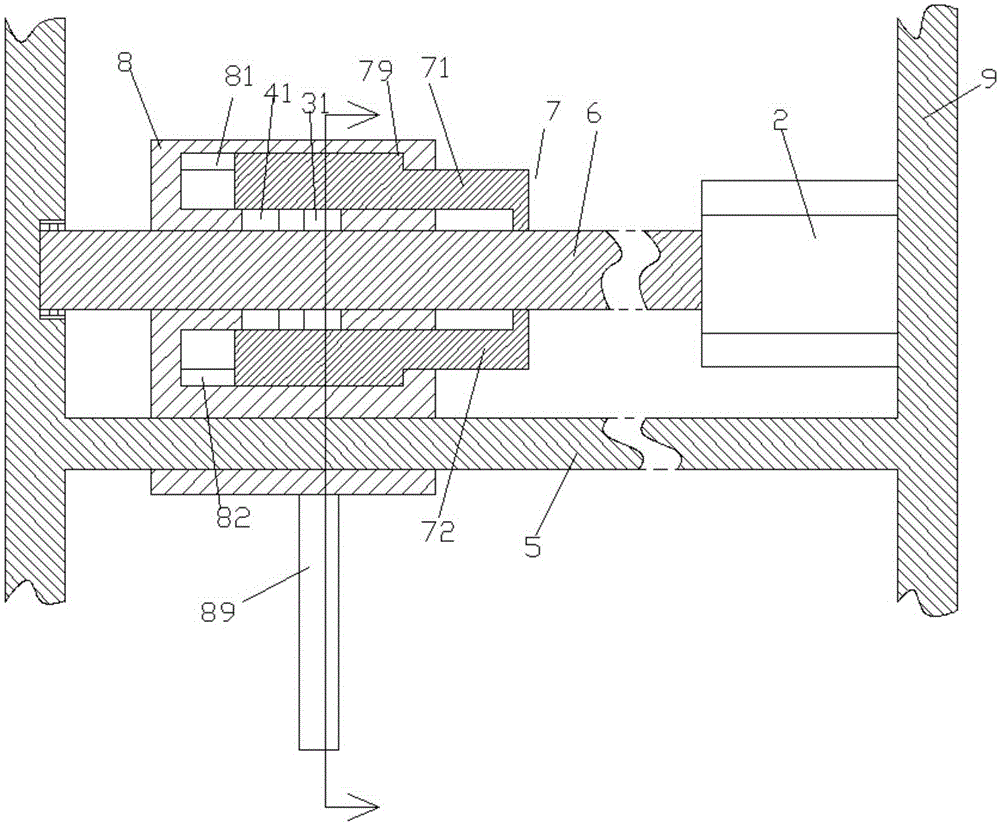

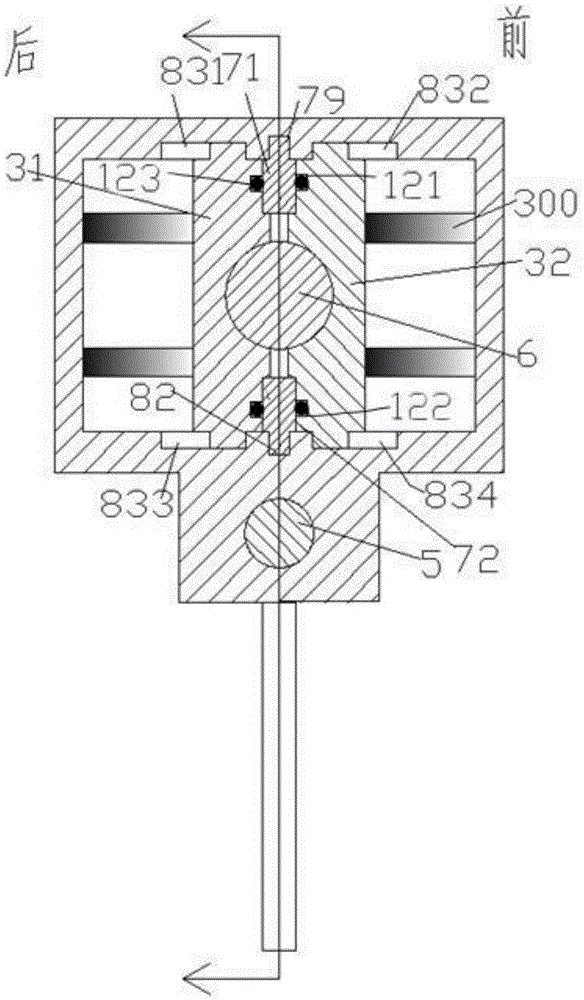

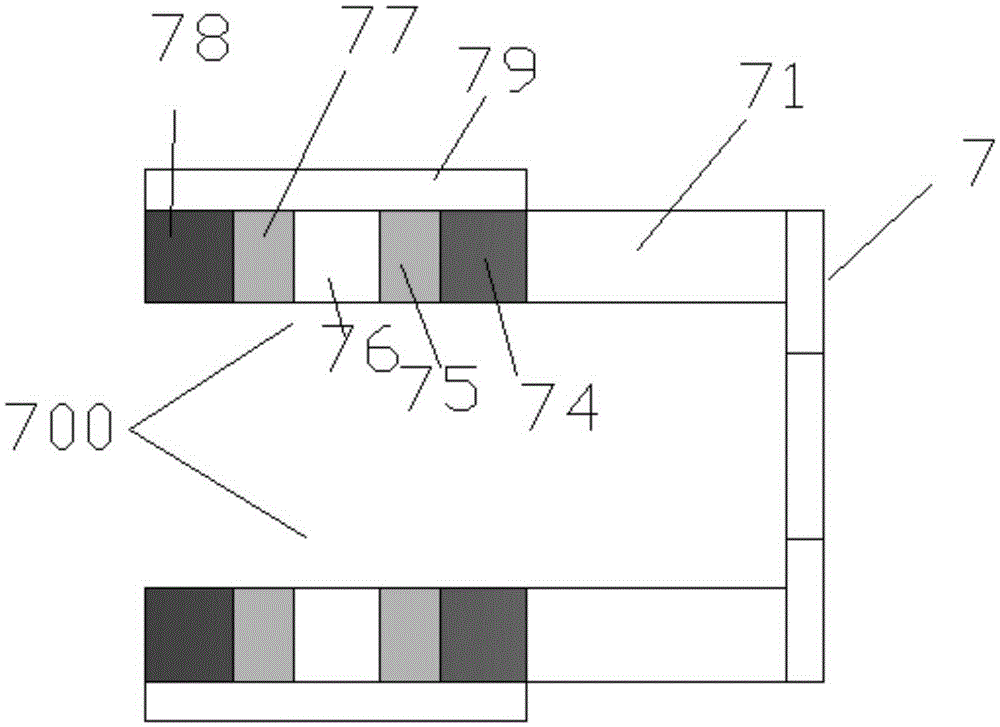

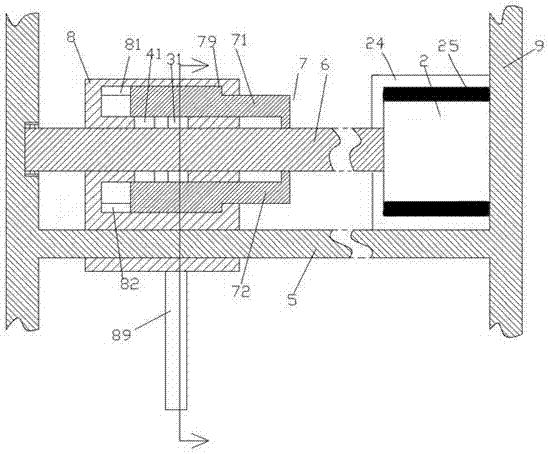

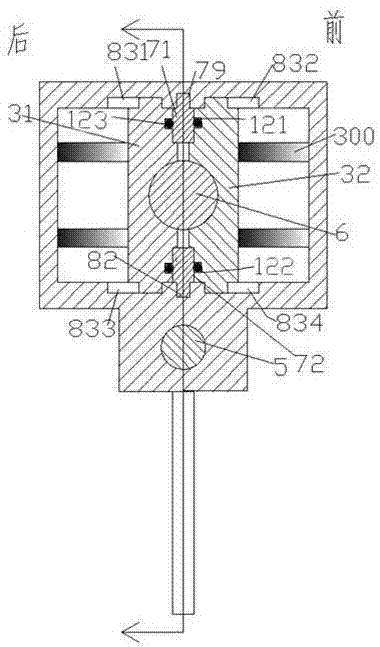

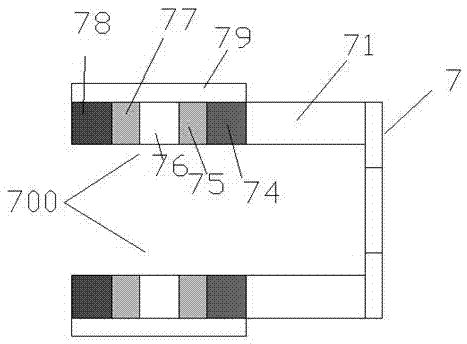

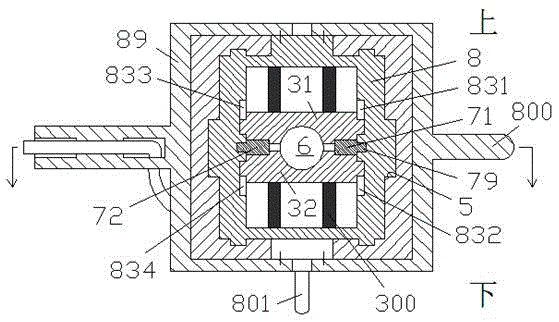

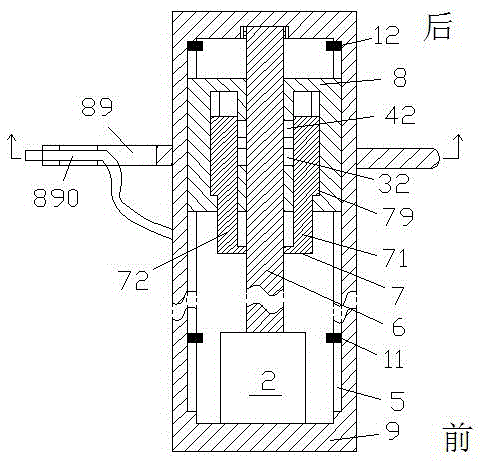

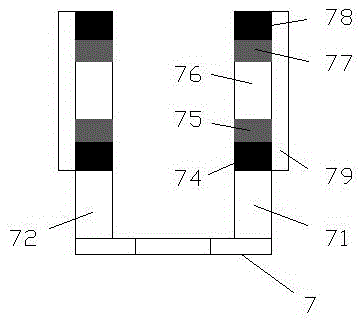

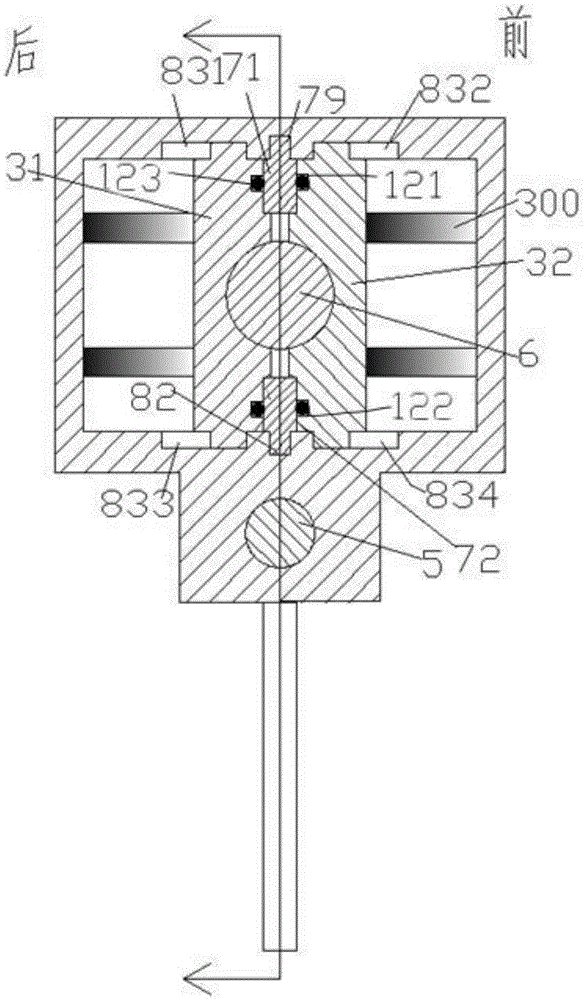

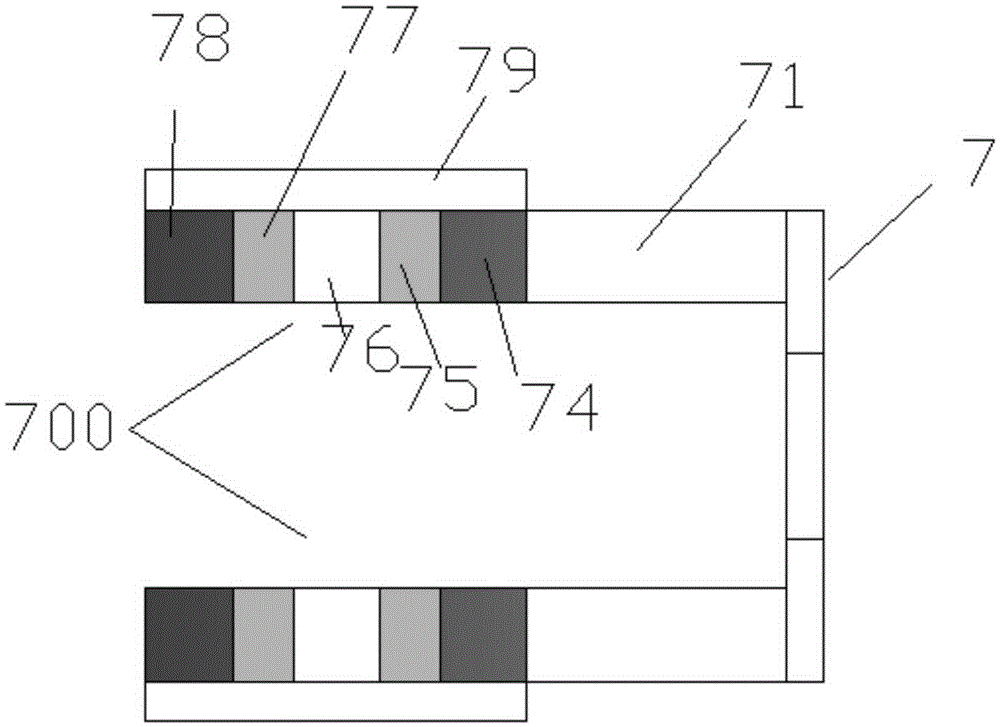

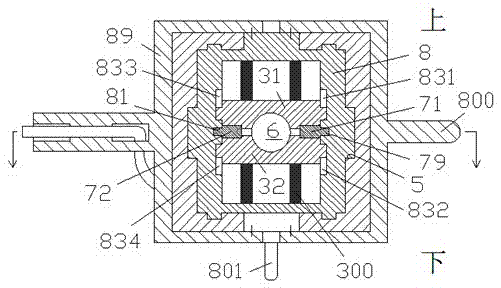

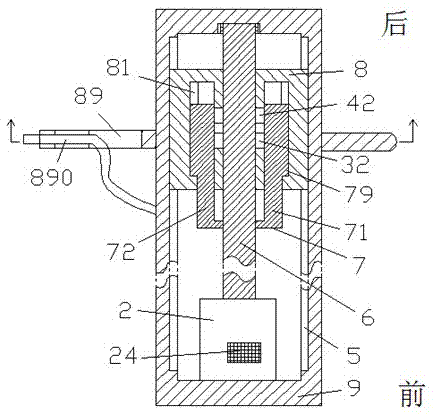

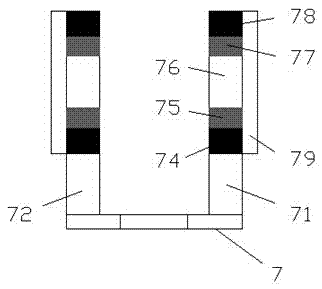

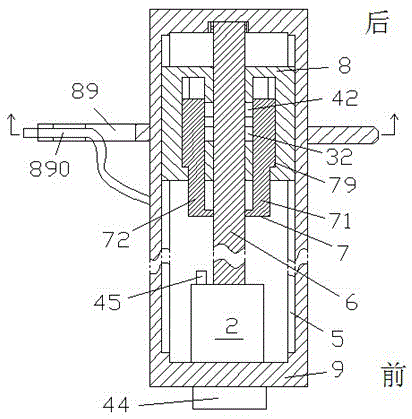

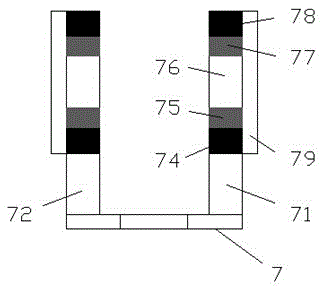

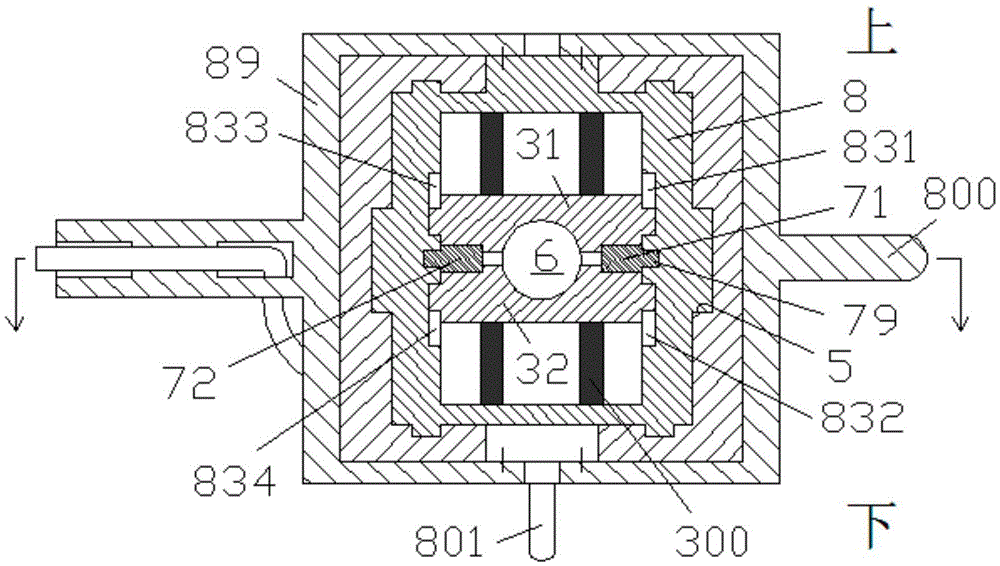

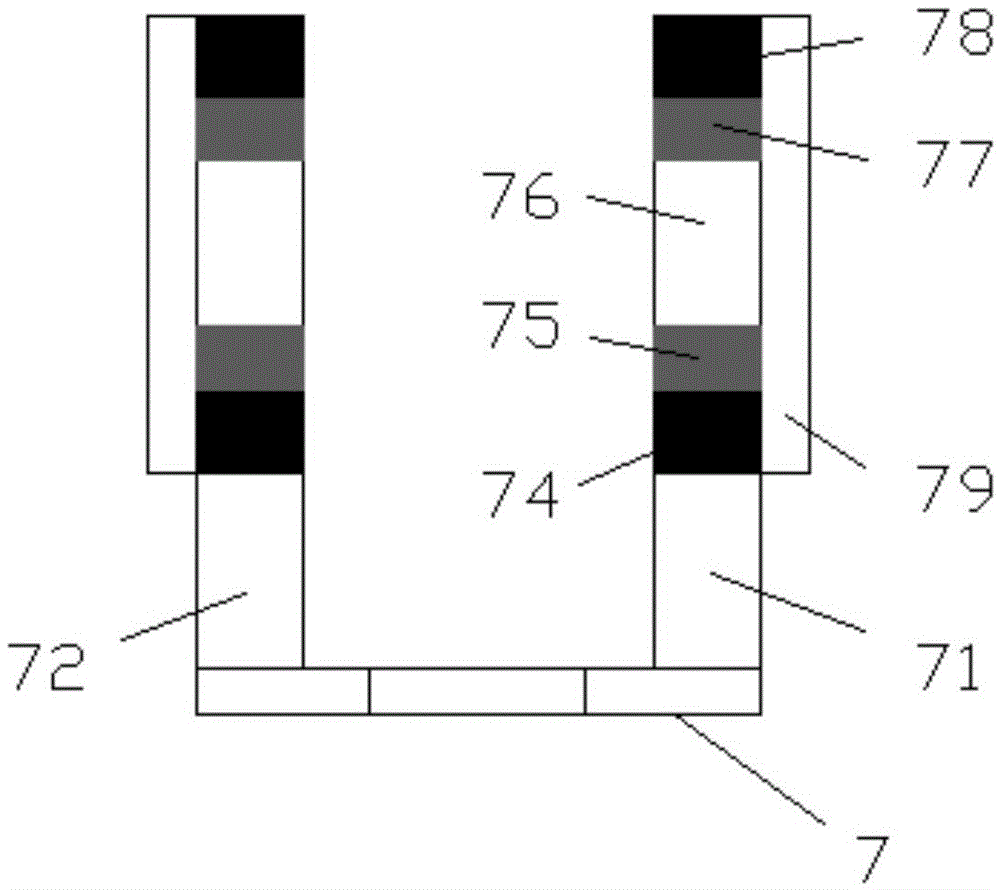

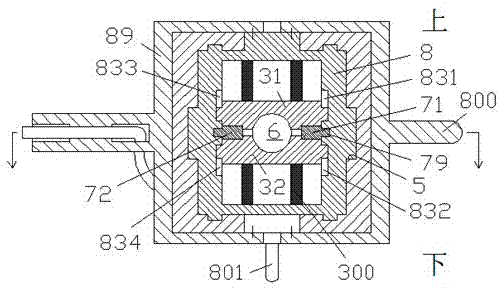

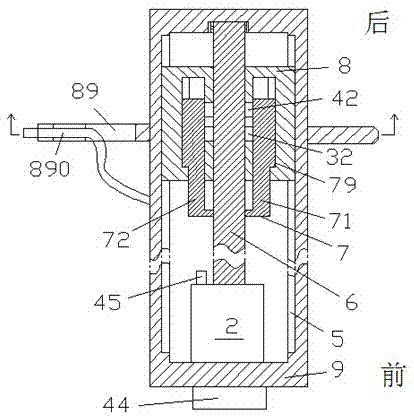

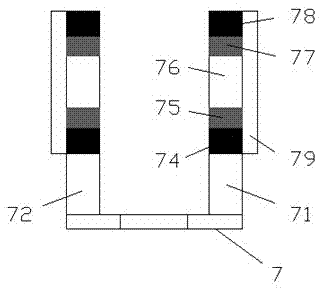

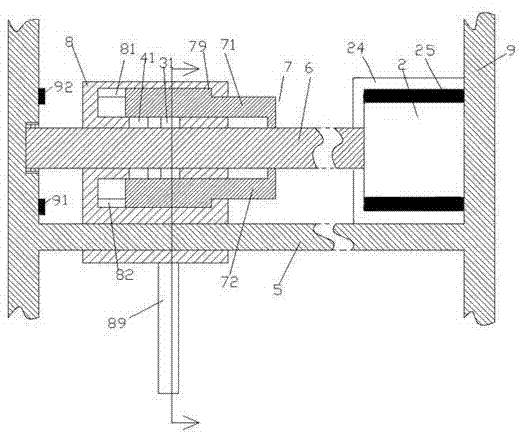

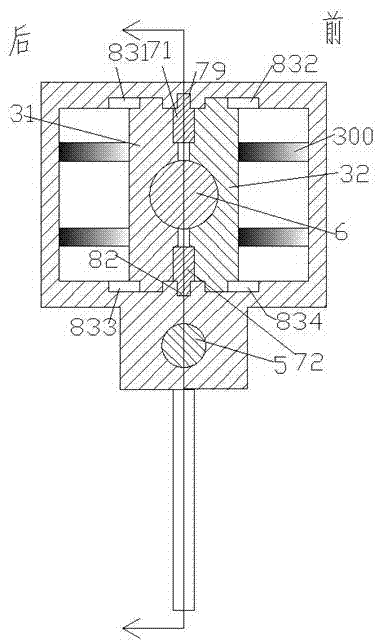

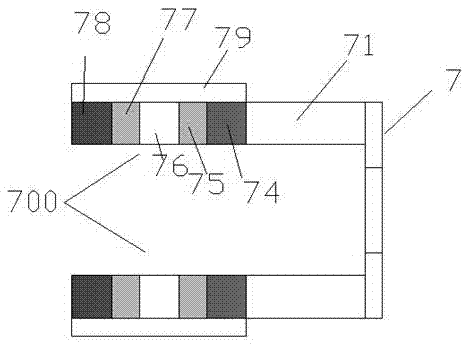

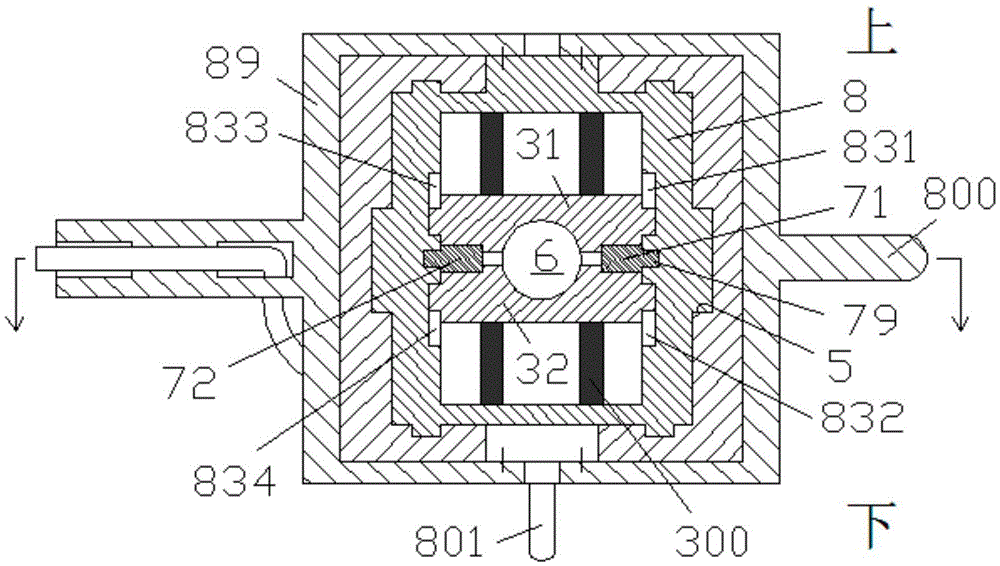

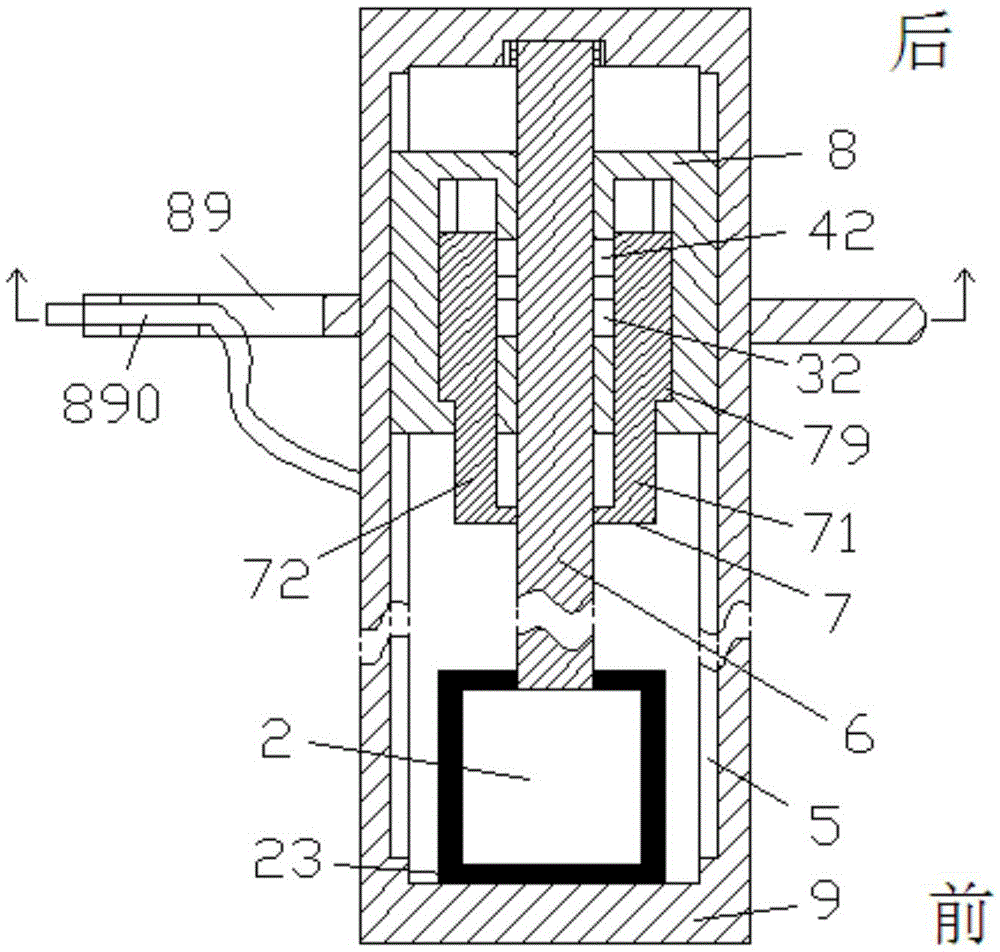

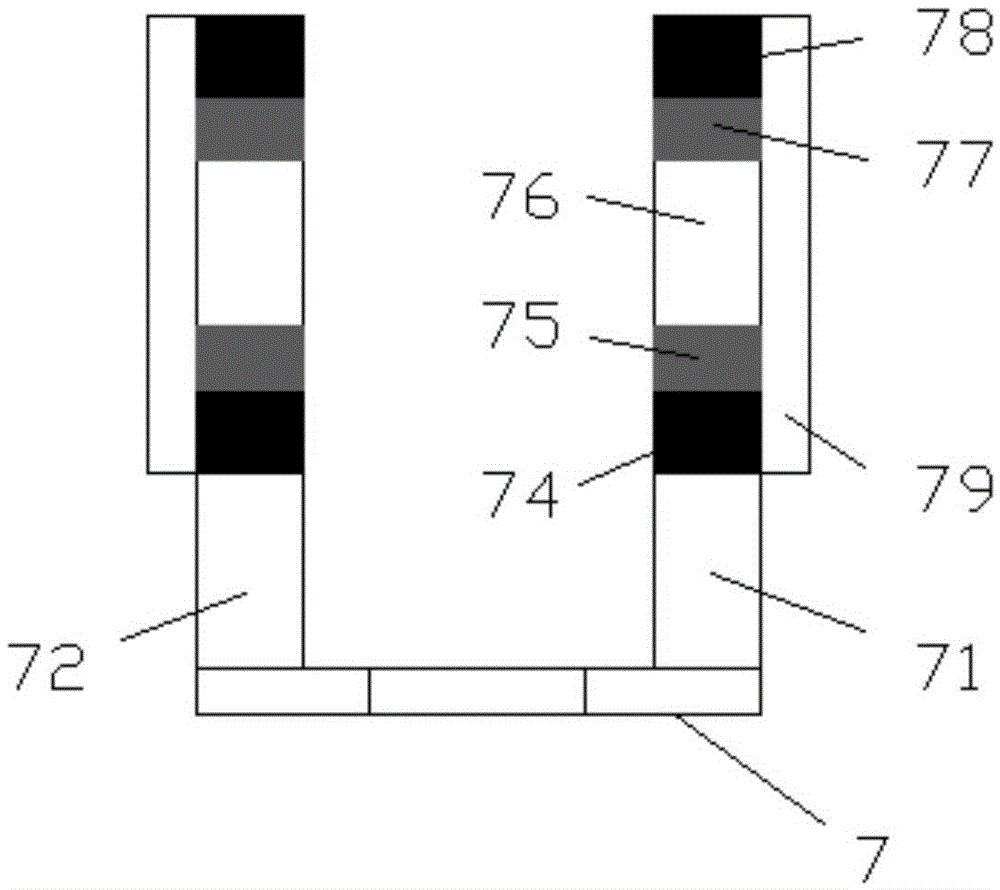

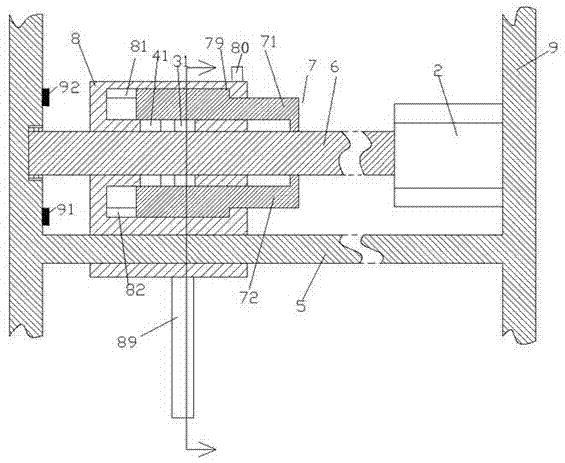

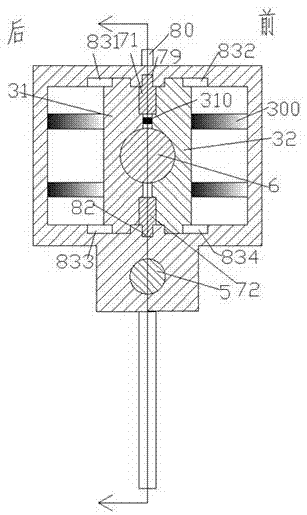

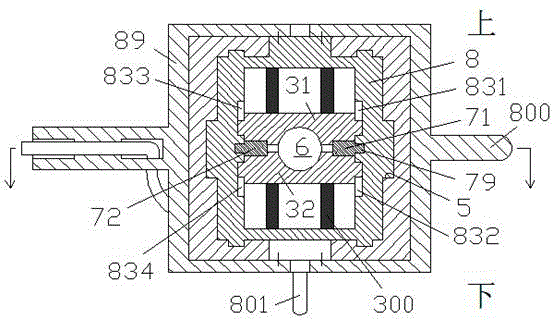

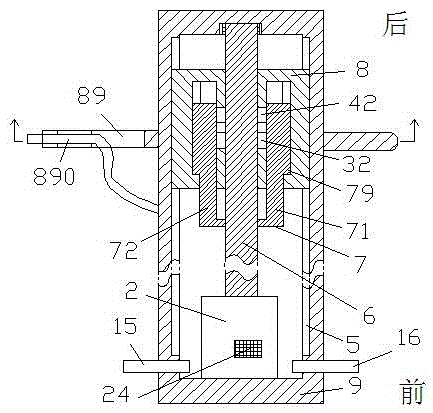

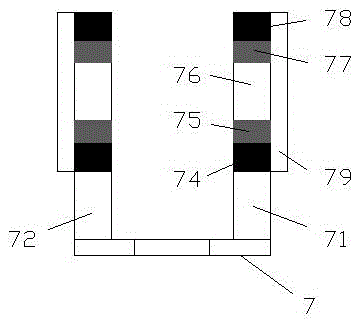

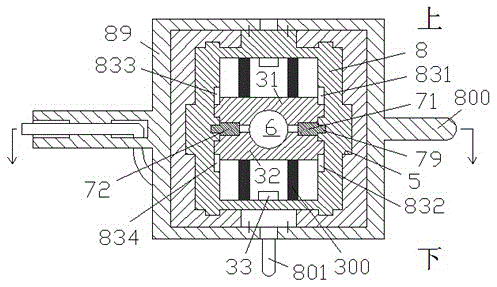

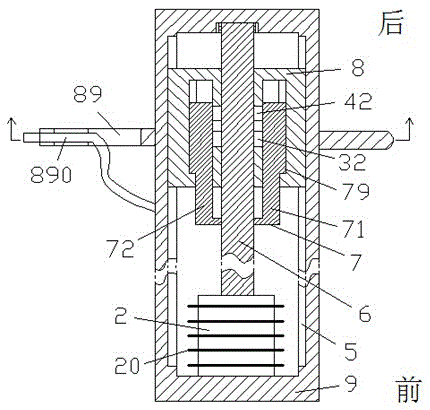

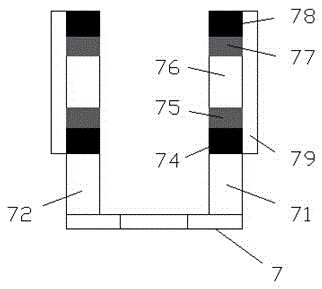

The invention discloses a limitable welding gun traveling mechanism for a welding machine and used for operating a welding gun to move in the welding process. The mechanism comprises a support frame (9), a traveling stand shell (8) and a welding gun connection portion (89) which is fixed to the lower side of the traveling stand shell (8) and used for being connected with the welding gun, wherein a threaded rod (6) which is driven by a motor (2) and rotatably installed on the support frame (9) and extends in the left-right direction penetrates through the upper portion of the traveling stand shell (8), a sliding guide rod (5) which is fixedly connected with the support frame (9) and extends in the left-right direction penetrates through the lower portion of the traveling stand shell (8), the traveling stand shell (8) is internally provided with a threaded clamping block pair and a siding clamping block pair, and the threaded clamping block pair comprises a front threaded block (32) and a rear threaded block (31) and can make a threaded concave portion be clamped and fitted to a threaded rod (6) under the action of a jacking and pressing elastic component (300).

Owner:韦红生

Executing method for plate spraying process for using damping cushion block to reduce vibration and using gas transmission system to exhaust heat

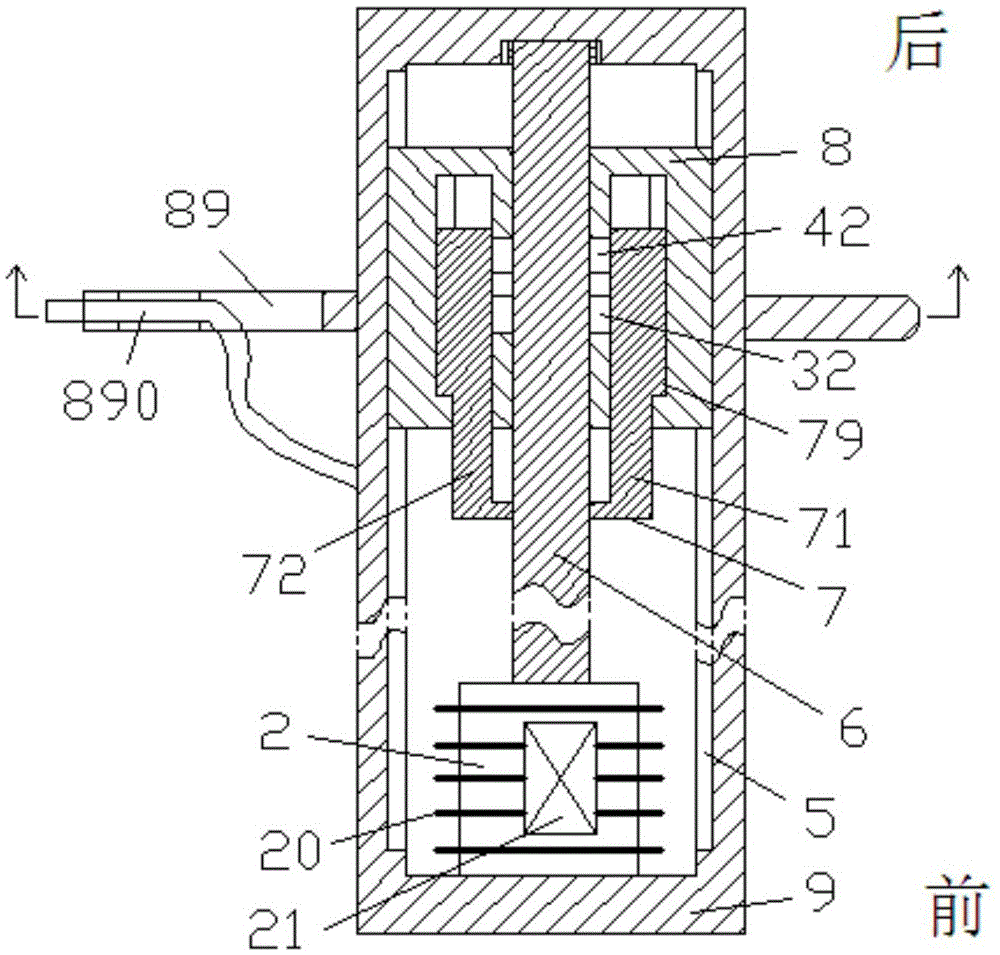

The invention relates to an executing method for a plate spraying process for using a damping cushion block to reduce vibration and using a gas transmission system to exhaust heat. The executing method uses a plate spraying device, and the plate spraying device is used for driving a spray head (890) for spraying to move in the spraying process. The plate spraying device comprises a support frame (9), a walking bracket (8) and a spray head bearing part (89), wherein the spray head bearing part (89) is fixed on the upper side and lower side of the walking bracket (8) and is used for clamping the spray head (890) for spraying; a threaded rod (6) which is driven by a motor (2), can be rotationally mounted on the support frame (9) and extends front and back penetrates through the walking bracket (8), and the walking bracket (8) can move front and back under the guidance of a guide track groove extending front and back in the support frame (9).

Owner:梁群清

Welding gun walking mechanism applied to welding machine and capable of indicating

InactiveCN105436777AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding gun walking mechanism applied to a welding machine and capable of indicating; and the welding gun walking mechanism is used for operating movement of a welding gun in the welding process. The welding gun walking mechanism comprises a support frame (9), a walking bracket shell (8), and a welding gun connecting part (89) fixed on the lower side of the walking bracket shell (8) and used for connecting with the welding gun, wherein a screw rod (6) driven by a motor (2) and rotationally mounted on the support frame (9) and extending left and right penetrates through the upper part of the walking bracket shell (8); a slide guide rod (5) fixedly connected with the support frame (9) and extending left and right penetrates through the lower part of the walking bracket shell (8); a thread clamping block pair and a slide clamping block pair are respectively arranged in the walking bracket shell (8); and the thread clamping block pair includes a front thread block (32) and a back thread block (31), and can enable a thread concave part to be tightly clamped and matched on the screw rod (6) under the effect of a jacking elastic element (300).

Owner:张帆

Execution method of plate spraying technology for reducing vibration by using cushion block

InactiveCN105413925AAffects slidingAvoid power consumptionSpraying apparatusEngineeringMechanical engineering

The invention discloses an execution method of a plate spraying technology for reducing vibration by using a cushion block. A plate spraying device is adopted and used for driving a spray head (890) for spraying to move in the spraying process and comprises a supporting frame (9), a walking bracket (8) and a spray head bearing portion (89) fixed from the upper side and the lower side of the walking bracket (8) and used for clamping the spray head (890) for spraying. A screw rod (6) which is driven by a motor (2) and rotationally installed on the supporting frame (9) and extends front and back penetrates through the walking bracket (8). The walking bracket (8) can move front and back under the guide of a guide rail groove (5) extending front and back in the supporting frame (9).

Owner:韦红生

Execution method of plate spraying process adopting solar panel for power generation and using electronic control device

InactiveCN105665243AAffects slidingAvoid power consumptionLiquid surface applicatorsCoatingsEngineeringSupport plane

A method for executing a plate spraying process using solar panels to generate electricity and using an electronic control device, which uses a plate spraying device, the plate spraying device is used to drive the spraying nozzle (890) to move during the spraying process, and includes: a support Frame (9), walking bracket (8) and the nozzle bearing part (89) fixed from the upper and lower sides of the walking bracket (8) and used to clamp the nozzle (890) for spraying, wherein, the motor (2) Driven and rotatably installed on the support frame (9) the screw rod (6) extending forward and backward passes through the walking bracket (8), and the walking bracket (8) can be positioned on the support frame (9) ) to move forward and backward under the guidance of the guide rail groove (5) extending forward and backward.

Owner:舒海球

Rapid heat-dissipation type welding gun walking mechanism

InactiveCN105397359AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

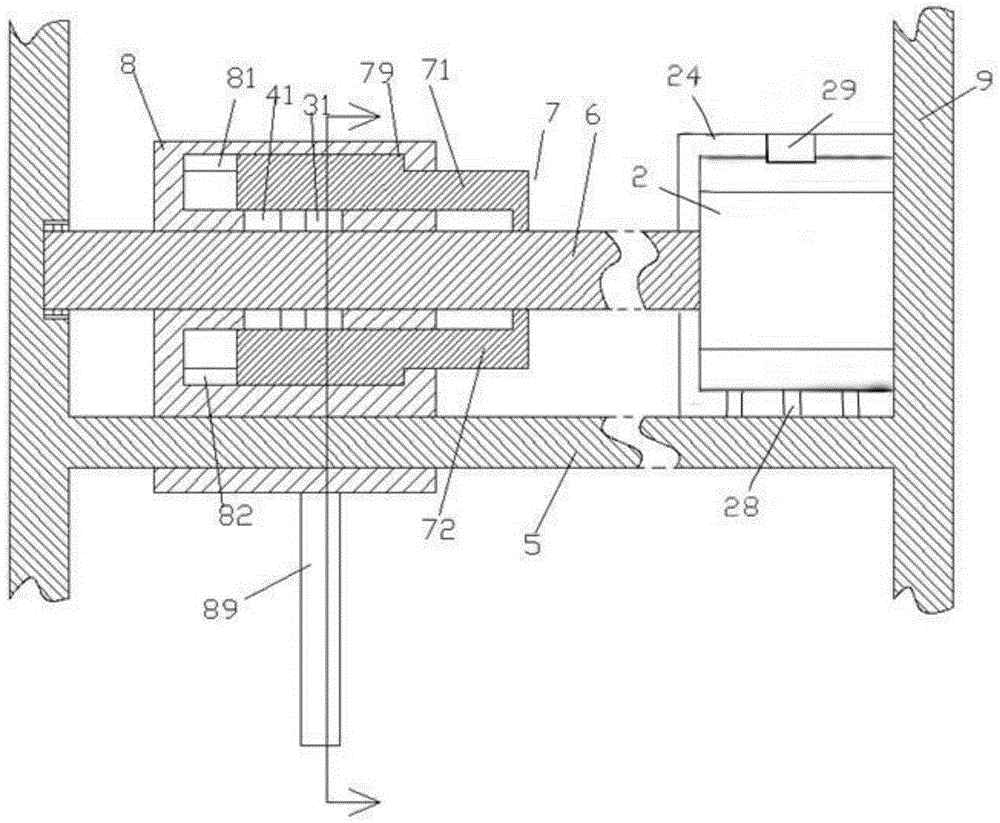

The invention provides a rapid heat-dissipation type welding gun walking mechanism. The rapid heat-dissipation type welding gun walking mechanism is used for controlling a welding gun to move during the welding process. The shockproof welding gun walking mechanism comprises a support frame (9), a walking bracket shell (8) and a welding gun connection part (89) fixedly arranged at the lower part of the walking bracket shell (8) and used for being connected with the welding gun. The inner side of the right end of the support frame (9) is fixedly provided with a protective housing (24). A motor (2) is arranged in the protective housing (24). A laterally extending screw (6) driven by the motor and rotatably arranged on the support frame (9) passes through the upper part of the walking bracket shell (8). A laterally extending sliding guide rod (5) and fixedly connected with the support frame (9) passes through the lower part of the walking bracket shell (8). The walking bracket shell (8) is internally and respectively provided with a threaded fixture block pair and a sliding fixture block pair. The threaded fixture block pair is composed of a front threaded block (32) and a rear threaded block (31). By means of the threaded fixture block pair, a threaded recess can be clamped and matched onto the screw (6) under the effect of an up-pressing elastic element (300).

Owner:桐乡市远邦传感器有限公司

Executing method of panel spraying process guided by ribbed guide groove

InactiveCN105413926AAffects slidingAvoid power consumptionLiquid surface applicatorsCoatingsSpray nozzleEngineering

Provided is an executing method of the panel spraying process guided by a ribbed guide groove. A panel spraying device is used for driving spraying nozzles (890) to move in the spraying process, and comprises a supporting frame (9), a walking bracket (8) and nozzle bearing parts (89) fixed to the upper side and the lower side of the walking bracket (8) and used for clamping the spraying nozzles (890), wherein a screw (6) driven by a motor (2), installed on the supporting frame (9) in a rotatable mode and extending forwards and backwards penetrates through the walking bracket (8), and the walking bracket (8) can move forwards and backwards under the guidance of the guide rail groove (5) capable of extending forwards and backwards in the supporting frame (9), and a thread clamping block set and a slide clamping block set are arranged in the walking bracket (8).

Owner:韦红生

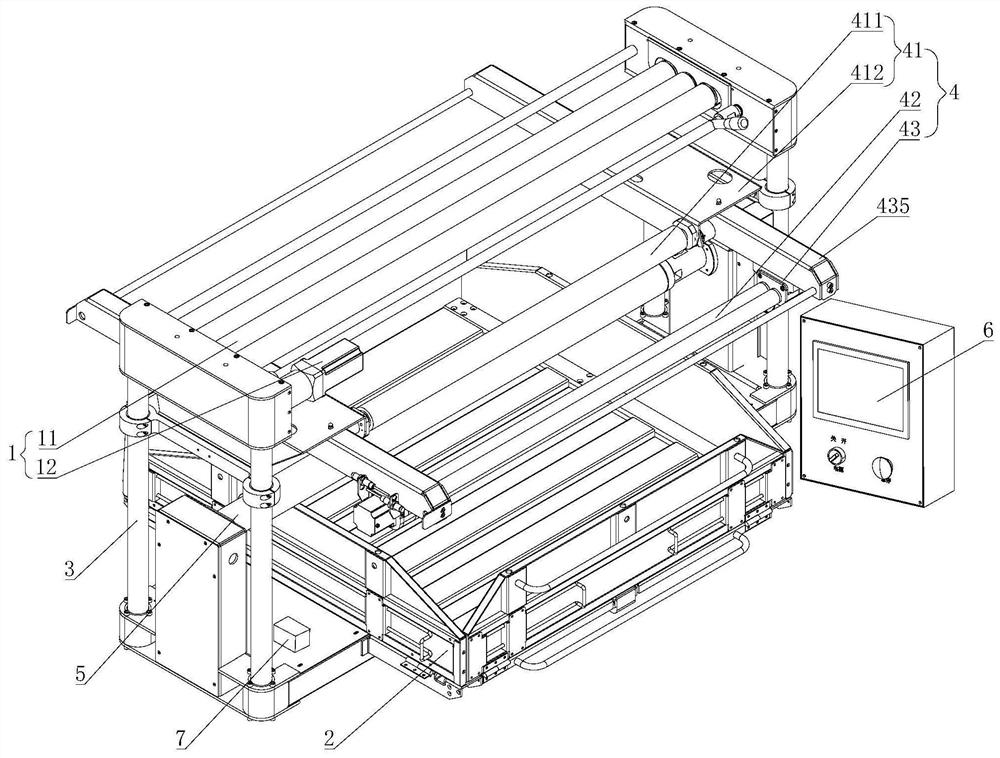

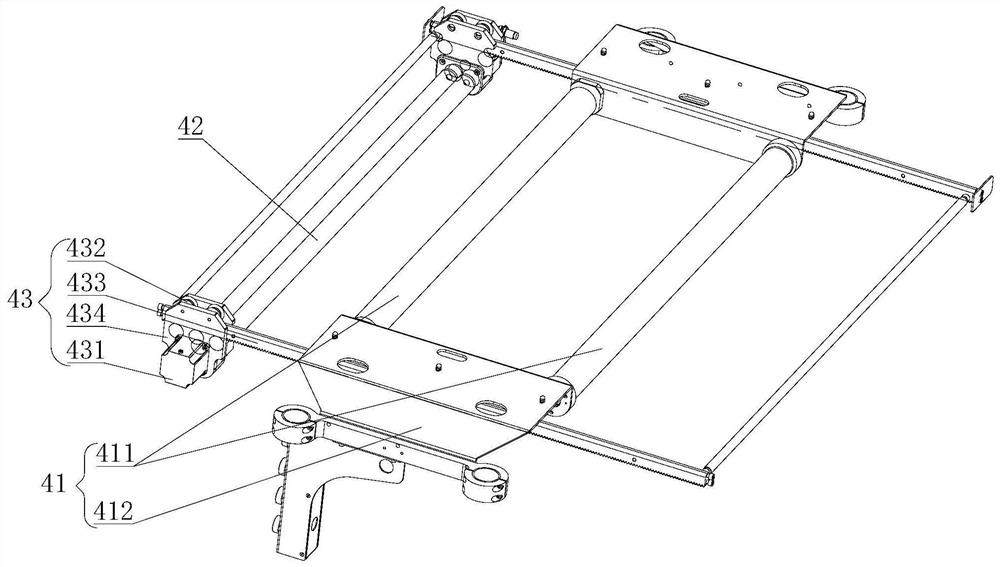

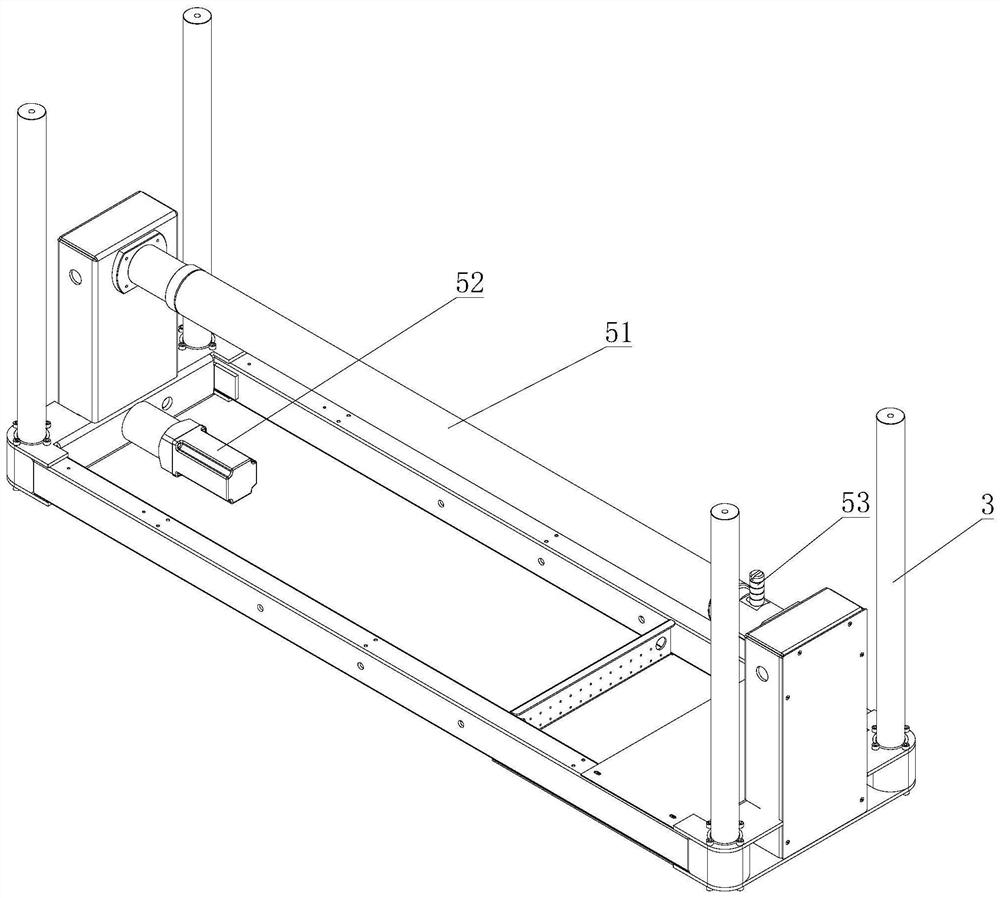

Rolling and swinging all-in-one machine for circular knitting machine set and control method thereof

PendingCN112678578AEven by forceStable forceFolding thin materialsWebs handlingElectric machineryElectric control

The invention discloses a rolling and swinging all-in-one machine for a circular knitting machine set, and belongs to the field of textile machinery. The machine comprises a feeding mechanism, a material support frame, a support column mechanism, a cloth pulling and swinging mechanism, a cloth rolling mechanism and an electric control box, and when the cloth pulling and swinging mechanism is erected between the feeding mechanism and the material support frame, cloth is folded on the material support frame in a swinging cloth folding manner. The cloth rolling mechanism is erected between the feeding mechanism and the material support frame so that the cloth can be connected to the cloth rolling mechanism in a rolling manner. The invention further discloses a control method for the rolling and swinging all-in-one machine. According to the rolling and swinging all-in-one machine for the circular knitting machine set and the control method of the rolling and swinging all-in-one machine, the conveying speed of the rolling and swinging all-in-one machine can be conveniently, accurately and reliably controlled, cloth stress is more balanced, it is guaranteed that the cloth conveying process is more stable and reliable, the production efficiency and quality are improved, and the material collecting manner can be changed according to needs. By means of the method, position information, motor servo signals or stepping signals of transmission rollers and cloth rollers can be conveniently and synchronously processed.

Owner:康美特(厦门)智控科技有限公司

Method for executing plate spraying process powered by solar energy

InactiveCN105457802AAffects slidingAvoid power consumptionSpraying apparatusEngineeringMechanical engineering

The invention relates to a method for executing a plate spraying process powered by solar energy. The method uses a plate spraying device, and the plate spraying device is used for driving a spray head (890) for spraying to move in the spraying process. The plate spraying device comprises a support frame (9), a walking bracket (8) and a spray head bearing part (89), wherein the spray head bearing part (89) is fixed from the upper side and the lower side of the walking bracket (8) and is used for clamping the spray head (890) for spraying; a threaded rod (6) which is driven by a motor (2), is rotationally mounted on the support frame (9), and extends back and forth penetrates through the walking bracket (8); the walking bracket (8) can move back and forth under the guide of a guide rail groove (5) extending back and forth in the support frame (9); a threaded clamping block group and a sliding clamping block group are respectively arranged in the walking bracket (8).

Owner:杨明华

Method for executing plate spraying process using LED lighting lamp for maintenance

The invention relates to a method for executing a plate spraying process using an LED lighting lamp for maintenance. The method uses a plate spraying device, and the plate spraying device is used for driving a spray head (890) for spraying to move in the spraying process. The plate spraying device comprises a support frame (9), a walking bracket (8) and a spray head bearing part (89), wherein the spray head bearing part (89) is fixed from the upper side and the lower side of the walking bracket (8) and is used for clamping the spray head (890) for spraying; a threaded rod (6) which is driven by a motor (2), is rotationally mounted on the support frame (9), and extends back and forth penetrates through the walking bracket (8); the walking bracket (8) can move back and forth under the guide of a guide rail groove (5) extending back and forth in the support frame (9); a threaded clamping block group and a sliding clamping block group are respectively arranged in the walking bracket (8).

Owner:杨明华

Welding gun walking mechanism of welding machine

InactiveCN105414831AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

Provided is a welding gun walking mechanism of a welding machine. The welding gun walking mechanism is used for operating a welding gun to move in the welding process and comprises a supporting frame (9), a walking support shell (8) and a welding gun connecting portion (89) which is fixed to the lower side of the walking support shell (8) and used for being connected with the welding gun. A screw rod (6) which is driven by a motor (2) and rotatably mounted on the supporting frame (9) and extends left and right penetrates through the upper portion of the walking support shell (8), a sliding guide rod (5) which is fixedly connected with the supporting frame (9) and extends left and right penetrates through the lower portion of the walking support shell (8), a thread clamping block pair and a sliding clamping block pair are arranged in the walking support shell (8), the thread clamping block pair comprises a front thread block (32) and a rear thread block (31), and threaded concave portions can be clamped and matched on the thread rod (6) under the action of a jacking elastic element (300).

Owner:陈良忠

Limitable welding gun walking mechanism with LED indication lamp

InactiveCN105499862AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesElastic componentWelding process

The invention relates to a limitable welding gun walking mechanism with an LED indication lamp. The limitable welding gun walking mechanism is used for operating a welding gun to move in a welding process. The limitable welding gun walking mechanism comprises a support frame (9), a walking bracket shell (8) and a welding gun connecting part (89), wherein the welding gun connecting part (89) is fixed on the lower side of the walking bracket shell (8) and is connected with the welding gun; a screw rod (6) which is driven by a motor (2), is rotatably mounted on the support frame (9) and can extend left and right penetrates through the upper part of the walking bracket shell (8), and a sliding guide rod (5) which is fixedly connected with the support frame (9) to extend penetrates through the lower part of the walking bracket shell (8); a threaded clamping block pair and a sliding clamping block pair are respectively arranged in the walking bracket shell (8); the threaded clamping block pair include a front threaded block (32) and a rear threaded block (31) and can drive a threaded recess to be clamped and matched to the screw rod (6) under the action of a top-pressure elastic component.

Owner:舒丽燕

Welding gun walking mechanism with LED indicating lamp and capable of dissipating heat

InactiveCN105436773AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a welding gun walking mechanism with an LED indicating lamp and capable of dissipating heat; and the welding gun walking mechanism is used for operating movement of a welding gun in the welding process. The welding gun walking mechanism comprises a support frame (9), a walking bracket shell (8), and a welding gun connecting part (89) fixed on the lower side of the walking bracket shell (8) and used for connecting with the welding gun, wherein a screw rod (6) driven by a motor (2) and rotationally mounted on the support frame (9) and extending left and right penetrates through the upper part of the walking bracket shell (8); a slide guide rod (5) fixedly connected with the support frame (9) and extending left and right penetrates through the lower part of the walking bracket shell (8); a thread clamping block pair and a slide clamping block pair are respectively arranged in the walking bracket shell (8); and the thread clamping block pair includes a front thread block (32) and a back thread block (31), and can enable a thread concave part to be tightly clamped and matched on the screw rod (6) under the effect of a jacking elastic element (300).

Owner:刘锦刚

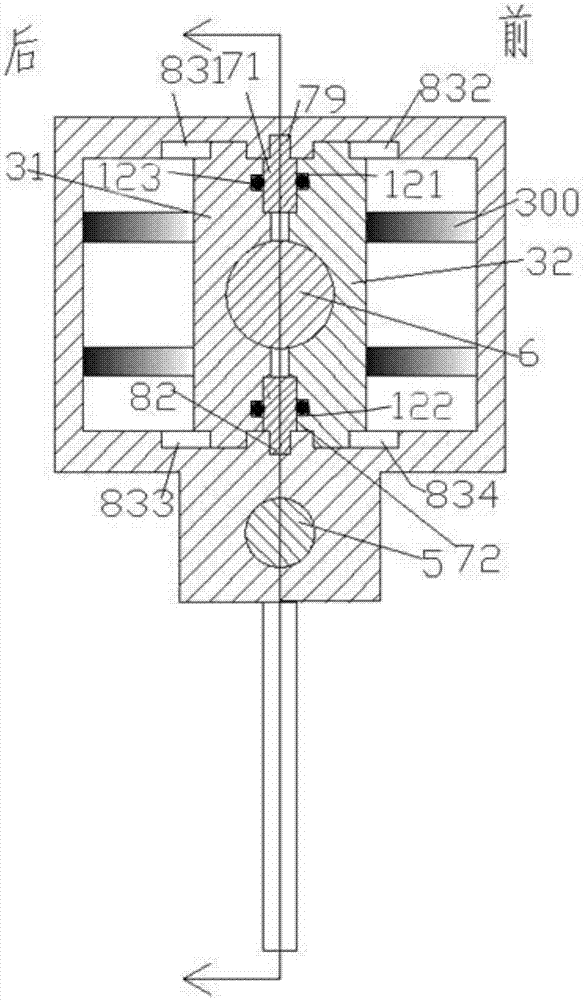

Welding gun walking mechanism with balls and capable of preventing vibration

InactiveCN105436775AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a welding gun walking mechanism with balls and capable of preventing vibration; and the welding gun walking mechanism is used for operating movement of a welding gun in the welding process. The welding gun walking mechanism comprises a support frame (9), a walking bracket shell (8), and a welding gun connecting part (89) fixed on the lower side of the walking bracket shell (8) and used for connecting with the welding gun, wherein a protection shell (24) is fixedly mounted on the inner side of the right end of the support frame (9); a motor (2) is mounted in the protection shell (24); a screw rod (6) driven by the motor (2) and rotationally mounted on the support frame (9) and extending left and right penetrates through the upper part of the walking bracket shell (8); a slide guide rod (5) fixedly connected with the support frame (9) and extending left and right penetrates through the lower part of the walking bracket shell (8); a thread clamping block pair and a slide clamping block pair are respectively arranged in the walking bracket shell (8); and the thread clamping block pair includes a front thread block (32) and a back thread block (31), and can enable a thread concave part to be tightly clamped and matched on the screw rod (6) under the effect of a jacking elastic element (300).

Owner:刘锦刚

Method for executing plate spraying process using limiting sensor for limiting

InactiveCN105457804AAffects slidingAvoid power consumptionSpraying apparatusElectric machineryEngineering

The invention relates to a method for executing a plate spraying process using a limiting sensor for limiting. The method uses a plate spraying device, and the plate spraying device is used for driving a spray head (890) for spraying to move in the spraying process. The plate spraying device comprises a support frame (9), a walking bracket (8) and a spray head bearing part (89), wherein the spray head bearing part (89) is fixed from the upper side and the lower side of the walking bracket (8) and is used for clamping the spray head (890) for spraying; a threaded rod (6) which is driven by a motor (2), is rotationally mounted on the support frame (9), and extends back and forth penetrates through the walking bracket (8); the walking bracket (8) can move back and forth under the guide of a guide rail groove (5) extending back and forth in the support frame (9).

Owner:舒海球

Welding gun walking mechanism with balls and rapid heat dissipation function

InactiveCN105414830AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElastic component

A welding gun walking mechanism with balls and a rapid heat dissipation function is used for operating a welding gun to move in the welding process. The welding gun walking mechanism with the balls and the rapid heat dissipation function comprises a support frame (9), a walking support shell (8) and a welding gun connecting part (89) which is fixed to the lower side of the walking support shell (8) and used for being connected with the welding gun, wherein a protection shell (24) is fixedly installed on the inner side of the right end of the support frame (9). A motor (2) is installed in the protection shell (24), a screw (6) which is driven by the motor (2) and rotatably installed on the support frame (9) and is capable of extending left and right penetrates through the upper portion of the walking support shell (8), a sliding guide rod (5) which is fixedly connected with the support frame (9) and is capable of extending left and right penetrates through the lower portion of the walking support shell (8), a threaded clamping block pair and a sliding clamping block pair are arranged in the walking support shell (8), the threaded clamping block pair comprises a front threaded block (32) and a rear threaded block (31), and threaded concave parts can be clamped on and matched with the screw (6) under the action of jacking elastic components (300).

Owner:陈良忠

Implementation method for board spraying process guided by convex strip guide slot and adjustable in spray speed

InactiveCN105435999AAffects slidingAvoid power consumptionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:吴笑

Welding gun walking mechanism applied to welding machine and capable of buffering

InactiveCN105436778AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a welding gun walking mechanism applied to a welding machine and capable of buffering; and the welding gun walking mechanism is used for operating movement of a welding gun in the welding process. The welding gun walking mechanism comprises a support frame (9), a walking bracket shell (8), and a welding gun connecting part (89) fixed on the lower side of the walking bracket shell (8) and used for connecting with the welding gun, wherein a screw rod (6) driven by a motor (2) and rotationally mounted on the support frame (9) and extending left and right penetrates through the upper part of the walking bracket shell (8); a slide guide rod (5) fixedly connected with the support frame (9) and extending left and right penetrates through the lower part of the walking bracket shell (8); a thread clamping block pair and a slide clamping block pair are respectively arranged in the walking bracket shell (8); and the thread clamping block pair includes a front thread block (32) and a back thread block (31), and can enable a thread concave part to be tightly clamped and matched on the screw rod (6) under the effect of a jacking elastic element (300).

Owner:张帆

Method for executing plate spraying process capable of contacting with alarm prompt

The invention relates to a method for executing a plate spraying process capable of contacting with an alarm prompt. The method uses a plate spraying device, and the plate spraying device is used for driving a spray head (890) for spraying to move in the spraying process. The plate spraying device comprises a support frame (9), a walking bracket (8) and a spray head bearing part (89), wherein the spray head bearing part (89) is fixed from the upper side and the lower side of the walking bracket (8) and is used for clamping the spray head (890) for spraying; a threaded rod (6) which is driven by a motor (2), is rotationally mounted on the support frame (9), and extends back and forth penetrates through the walking bracket (8); the walking bracket (8) can move back and forth under the guide of a guide rail groove (5) extending back and forth in the support frame (9); a threaded clamping block group and a sliding clamping block group are respectively arranged in the walking bracket (8).

Owner:舒丽燕

Implementation method of plate spraying process using exhaust fan for cooling acceleration

InactiveCN105642483AAffects slidingAvoid power consumptionSpraying apparatusEngineeringAcceleration Unit

Owner:陈良忠

Implementation method for board spraying process with contactable lamplight prompting

InactiveCN105436000AAffects slidingAvoid power consumptionLiquid surface applicatorsCoatingsEngineeringSupport plane

Owner:吴笑

Welding gun walking mechanism capable of preventing vibration and collision

InactiveCN105436771AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a welding gun walking mechanism capable of preventing vibration and collision; and the welding gun walking mechanism is used for operating movement of a welding gun in the welding process. The welding gun walking mechanism comprises a support frame (9), a walking bracket shell (8), and a welding gun connecting part (89) fixed on the lower side of the walking bracket shell (8) and used for connecting with the welding gun, wherein a protection shell (24) is fixedly mounted on the inner side of the right end of the support frame (9); a motor (2) is mounted in the protection shell (24); a screw rod (6) driven by the motor (2) and rotationally mounted on the support frame (9) and extending left and right penetrates through the upper part of the walking bracket shell (8); a slide guide rod (5) fixedly connected with the support frame (9) and extending left and right penetrates through the lower part of the walking bracket shell (8); a thread clamping block pair and a slide clamping block pair are respectively arranged in the walking bracket shell (8); and the thread clamping block pair includes a front thread block (32) and a back thread block (31), and can enable a thread concave part to be tightly clamped and matched on the screw rod (6) under the effect of a jacking elastic element (300).

Owner:刘锦刚

Execution method of plate spraying process for reducing noise by using soundproof box

InactiveCN105554677AAffects slidingAvoid power consumptionElectrical transducersEngineeringSupport plane

The invention relates to an execution method of a plate spraying process for reducing noise by using a soundproof box. A plate spraying device is used; the plate spraying device is used for driving a spray head (890) for spraying to move in the spraying process; the plate spraying device comprises a support frame (9), a travelling support frame (8) and a spray head bearing part (89), wherein the spray head bearing part (89) is fixed from the upper and lower sides of the travelling support frame (8) and used for clamping the spray head (890) for spraying, wherein a screw (6), which is driven by a motor (2), rotatably installed on the support frame (9) and extends horizontally, passes through the travelling support frame (8); and the travelling support frame (8) can horizontally move under the guide of a guide rail groove (5) horizontally extending in the support frame (9).

Owner:韦红生

Welding gun walking mechanism with LED indicating lamp and capable of preventing collision

InactiveCN105436780AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding gun walking mechanism with an LED indicating lamp and capable of preventing collision; and the welding gun walking mechanism is used for operating movement of a welding gun in the welding process. The welding gun walking mechanism comprises a support frame (9), a walking bracket shell (8), and a welding gun connecting part (89) fixed on the lower side of the walking bracket shell (8) and used for connecting with the welding gun, wherein a screw rod (6) driven by a motor (2) and rotationally mounted on the support frame (9) and extending left and right penetrates through the upper part of the walking bracket shell (8); a slide guide rod (5) fixedly connected with the support frame (9) and extending left and right penetrates through the lower part of the walking bracket shell (8); a thread clamping block pair and a slide clamping block pair are respectively arranged in the walking bracket shell (8); and the thread clamping block pair includes a front thread block (32) and a back thread block (31), and can enable a thread concave part to be tightly clamped and matched on the screw rod (6) under the effect of a jacking elastic element (300).

Owner:舒丽燕

Position-limitable welding gun travelling mechanism provided with ball

InactiveCN105436782AAffects slidingAvoid power consumptionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a position-limitable welding gun travelling mechanism provided with a ball. The welding gun traveling mechanism is used for operating a welding gun to move during a welding process and comprises a supporting frame (9), a travelling bracket shell (8) and a welding gun connecting part (89), wherein the welding gun connecting part (89) is fixedly arranged at the lower side of the travelling bracket shell (8) and is connected with the welding gun; a screw rod (6) driven by a motor (2), rotationally mounted on the supporting frame (9) and extending leftwards and rightwards passes through the upper part of the travelling bracket shell (8); an extending sliding guide rod (5) fixedly connected with the supporting frame (9) passes through the lower part of the travelling bracket shell (8); a threaded clamping block pair and a sliding clamping block pair are respectively arranged in the travelling bracket shell (8); the threaded clamping block pair comprises a front thread block (32) and a rear thread block (31); moreover, the threaded clamping block pair can be used for clamping a threaded concave part and enabling the threaded concave part to be matched with the screw rod (6) under the effect of an elastic jacking part (300).

Owner:陈良忠

Implementing method for plate spraying process with heat extraction conducted through gas transmission system and adjustable spraying speed

InactiveCN105665202AAffects slidingAvoid power consumptionSpraying apparatusEngineeringGas transmission

A method for executing a plate spraying process using an air transmission system for heat removal and adjustable spraying speed, which uses a plate spraying device, the plate spraying device is used to drive the spraying nozzle (890) to move during the spraying process, and includes : the supporting frame (9), the walking bracket (8) and the nozzle bearing part (89) fixed from the upper and lower sides of the walking bracket (8) and used to clamp the spray nozzle (890) for spraying, wherein the motor ( 2) Drive and rotatably install the screw rod (6) extending back and forth on the support frame (9) to pass through the walking bracket (8), and the walking bracket (8) can be positioned on the support frame Move back and forth under the guidance of the guide rail groove (5) extending back and forth in (9).

Owner:杨明华

Execution method of plate spraying technology using cooling fins to conduct heat and using LED illuminating lamps for maintenance

InactiveCN105537076AAffects slidingAvoid power consumptionLiquid surface applicatorsSpraying apparatusSpray nozzleEngineering

Disclosed is an execution method of a plate spraying technology characterized by using cooling fins to conduct heat and using LED illuminating lamps for maintenance. A plate spraying device is used. The plate spraying device is used for driving a spraying nozzle (890) for spraying to move in the spraying process, and comprises a supporting frame (9), a travelling bracket (8) and a spraying nozzle bearing portion (89), wherein the spraying nozzle bearing portion (89) is fixed on the upper side and the lower side of the travelling bracket (8) and is used for clamping the spraying nozzle (890) for spraying. A threaded rod (6) which is driven by a motor (2), is installed on the supporting frame (9) in a rotatable mode and extends forwards and backwards to penetrate through the travelling bracket (8). The travelling bracket (8) can be guided by a guide rail groove (5) to move forwards and backwards, wherein the guide rail groove (5) is formed in the supporting frame (9) and extends forwards and backwards.

Owner:吴笑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com