Limitable welding gun traveling mechanism for welding machine

A traveling mechanism and welding torch technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of impossible manual operation and increase of extra cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

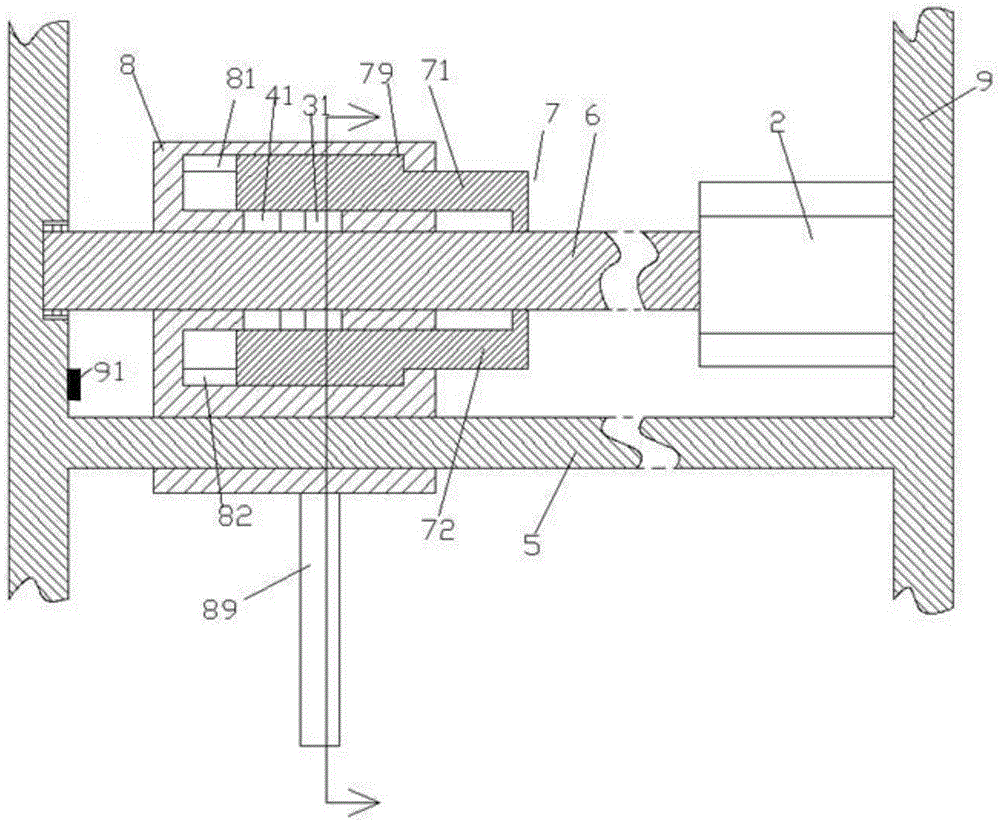

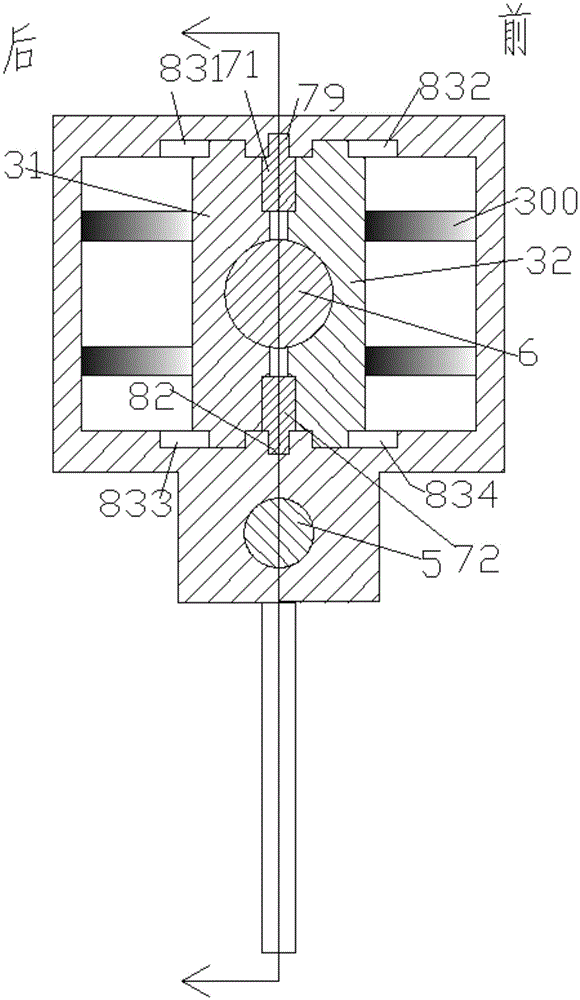

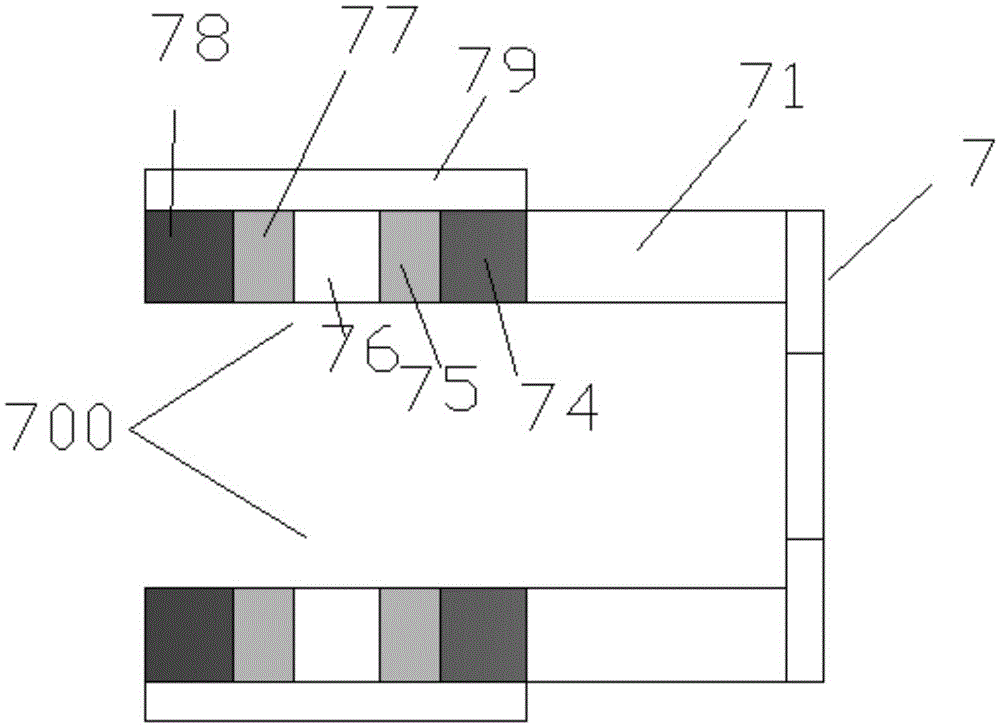

[0011] Combine below Figure 1-4 The present invention will be described in detail.

[0012] A position-limitable welding torch traveling mechanism for a welding machine according to an embodiment, used for operating the welding torch to move during the welding process, including a support frame 9, a traveling support housing 8 and fixed on the lower side of the traveling support housing 8 A welding torch connecting portion 89 for connecting with a welding torch, wherein the left and right extending screw rod 6 driven by the motor 2 and rotatably installed on the support frame 9 passes through the upper part of the traveling support housing 8, and is connected with the The extended sliding guide rod 5 of the effect of the fixed connection of the support frame 9 passes through the bottom of the walking frame housing 8, and the threaded clamping block pair and the sliding clamping block pair are respectively arranged in the walking frame housing 8, and the threaded clamping bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com