Welding gun walking mechanism with balls and rapid heat dissipation function

A technology of walking mechanism and welding torch, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve the problems of impossible manual operation and additional cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

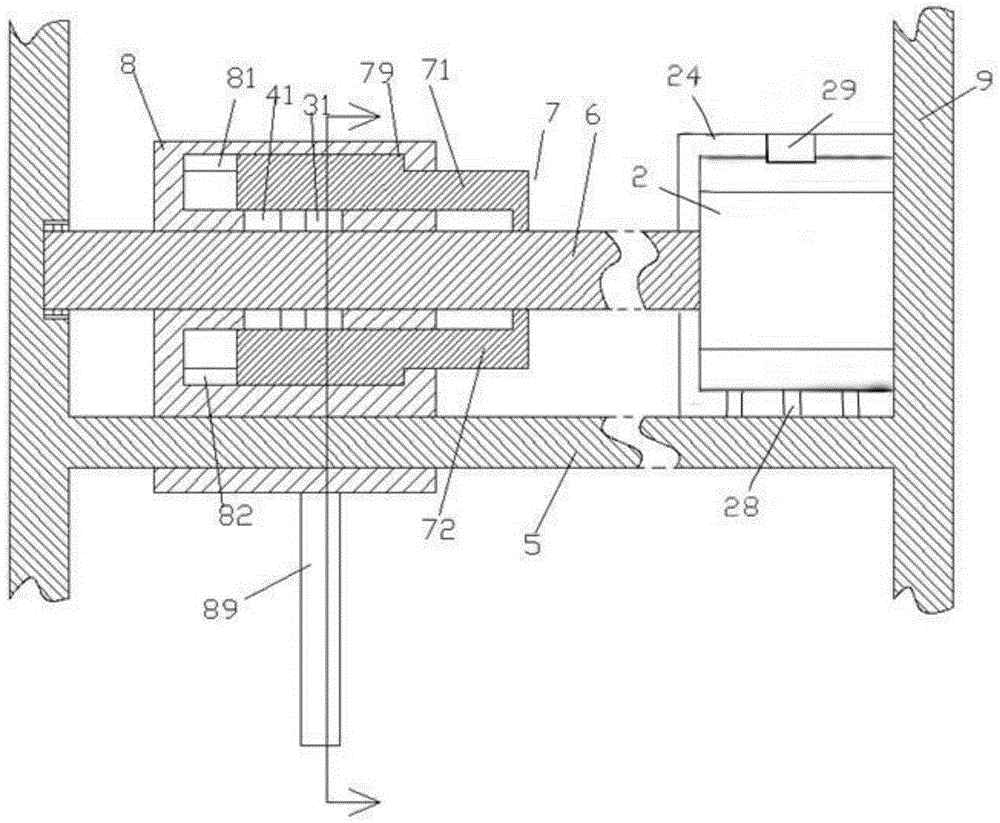

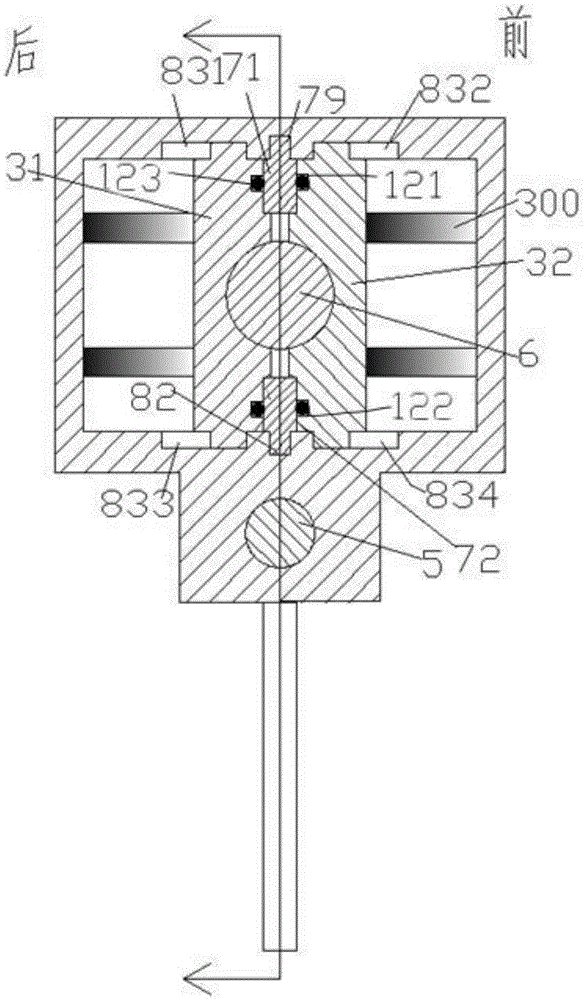

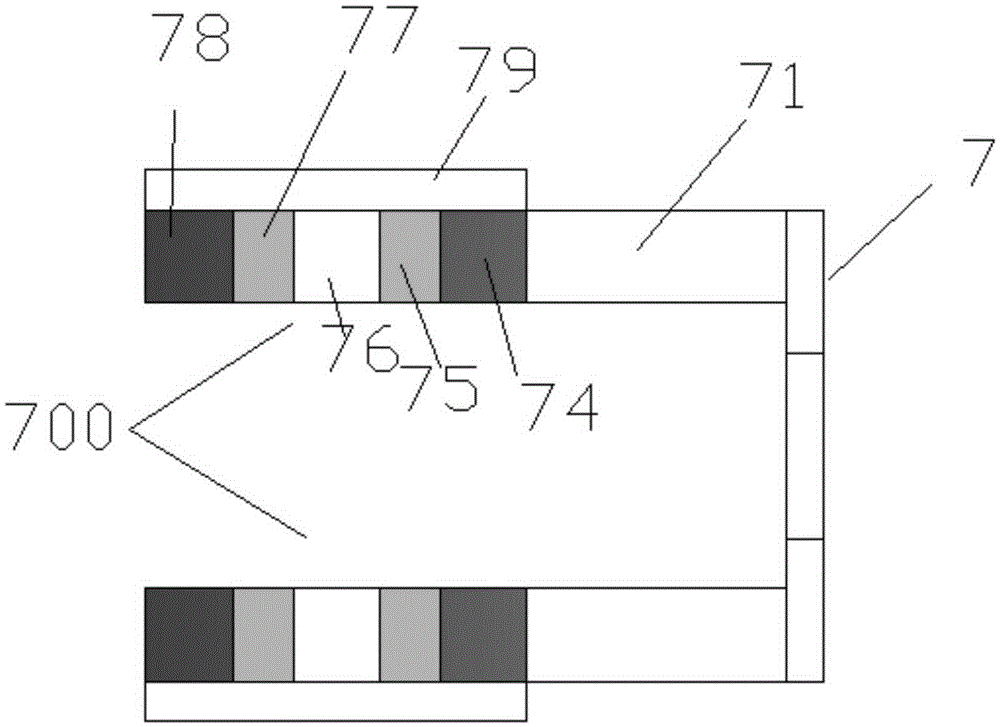

[0011] Combine below Figure 1-4 The present invention will be described in detail.

[0012] According to an embodiment, a welding torch traveling mechanism with balls and capable of rapidly dissipating heat is used to operate the welding torch to move during the welding process, including a support frame 9, a traveling support housing 8, and a device fixed on the lower side of the traveling support housing 8. In the welding torch connecting portion 89 connected with the welding torch, a protective casing 24 is fixedly installed on the inner side of the right end of the support frame 9, and a motor 2 is installed in the protective casing 24, which is driven by the motor 2 and rotatably installed on the The screw rod 6 extending left and right on the support frame 9 passes through the upper part of the walking support housing 8, and the extended sliding guide rod 5 fixedly connected with the support frame 9 passes through the lower part of the walking support housing 8 , the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com