Rolling and swinging all-in-one machine for circular knitting machine set and control method thereof

An all-in-one machine and unit technology, which is applied in the direction of winding strips, folding thin materials, thin material processing, etc., can solve the automatic adjustment changes of cloth rolling rollers, uneven force on cloth, and reduce the quality and efficiency of cloth winding. problems, to achieve the effect of improving production efficiency and quality, stable and reliable transmission process, and stable and reliable transportation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

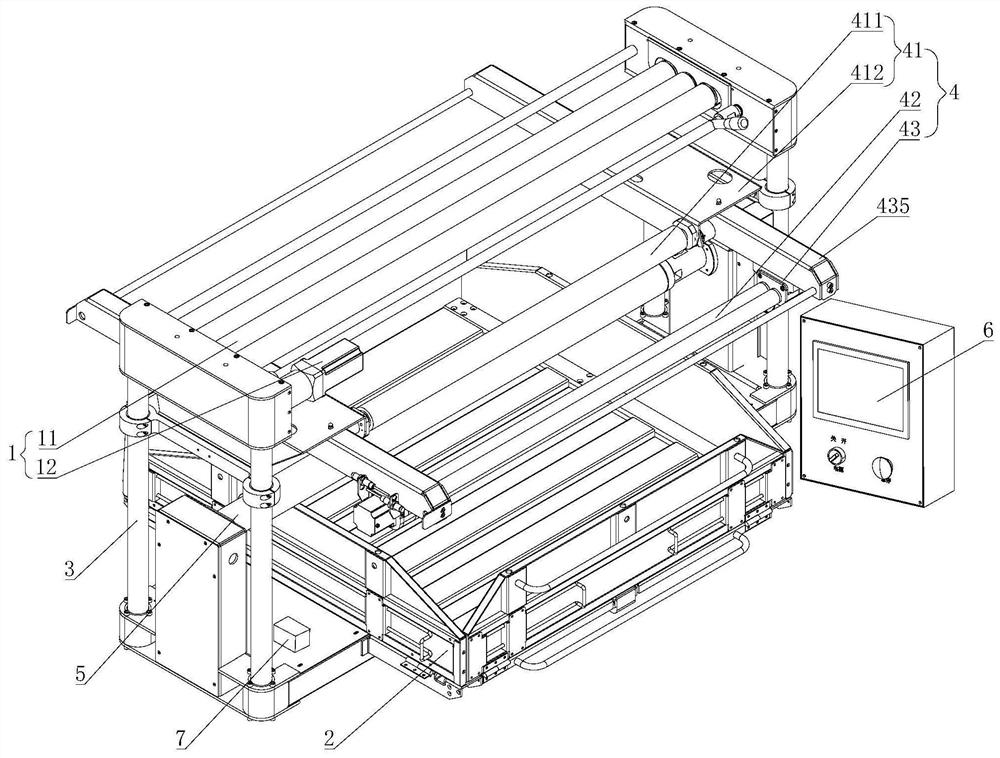

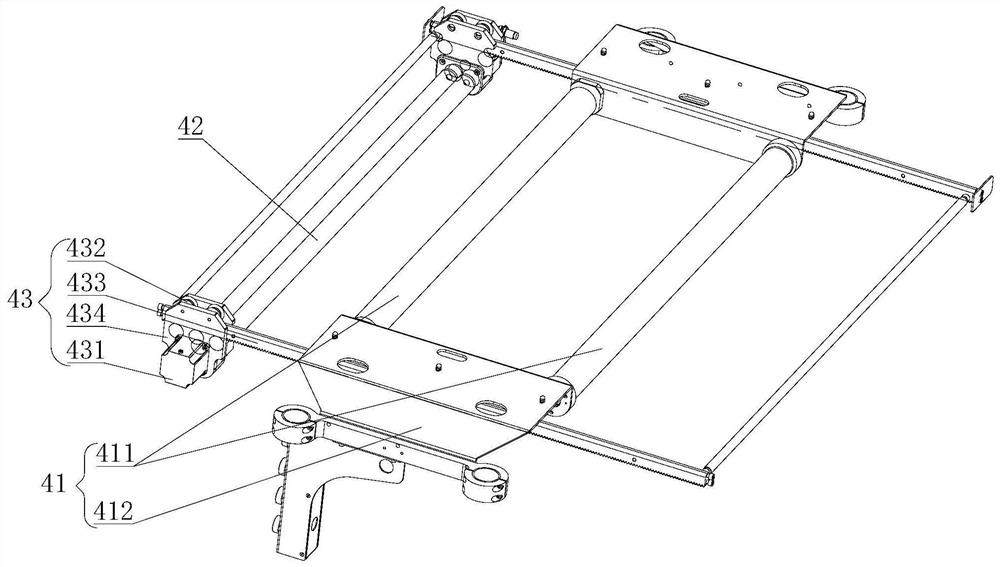

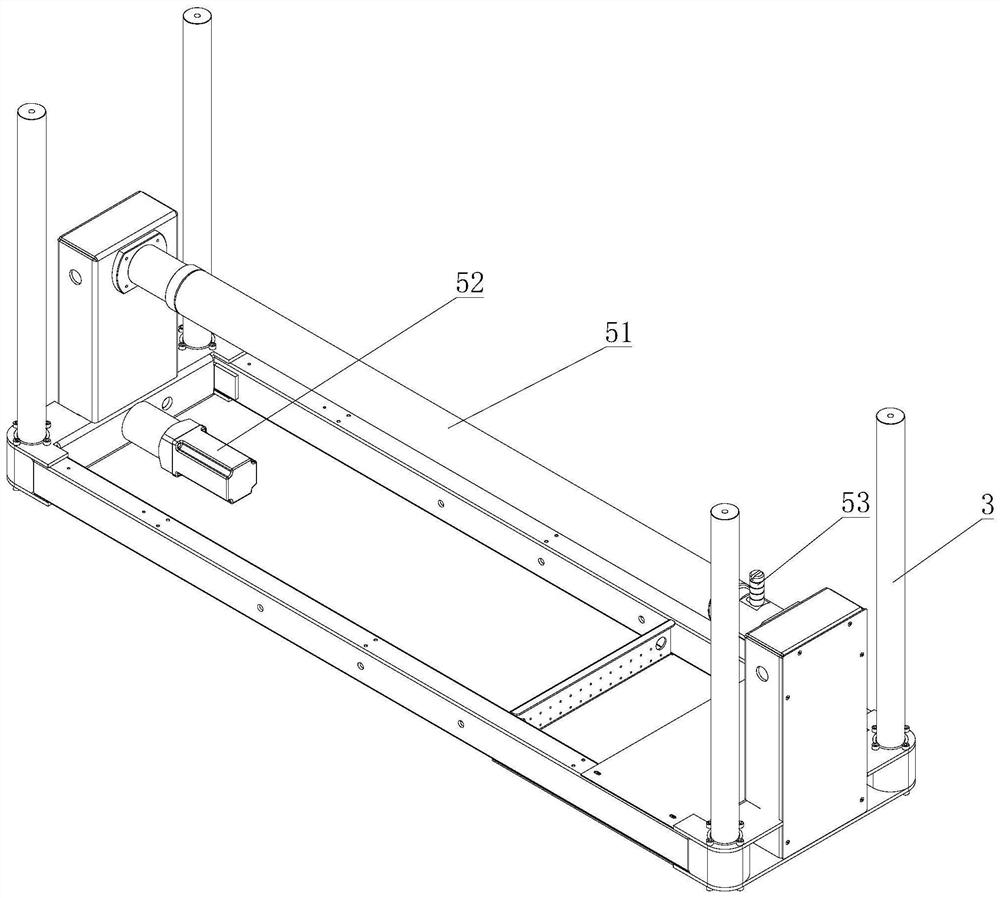

[0030] like Figure 1 to Figure 4 As shown, the rolling and pendulum integrated machine used in the large circular knitting machine provided in the first embodiment. In order to accurately and reliably control the conveying speed of the rolling and swinging machine, make the force on the cloth more balanced, ensure a more stable and reliable cloth conveying process, improve production efficiency and quality, and change the receiving method according to demand. Further, the rolling and pendulum integrated machine for the large circular knitting unit includes a feeding mechanism 1, a material support frame 2, a pillar mechanism 3, a pulling and swinging mechanism 4, a cloth rolling mechanism 5 and an electric control box 6, and the feeding mechanism 1 is fixed on the pillar mechanism 3, the support frame 2 is set under the feeding mechanism 1, the signal end of the feeding mechanism 1, the signal end of the pulling and swinging mechanism 4, and the signal end of the rolling mechan...

Embodiment 2

[0039] like Figure 1 to Figure 4 As shown, in the control method for the rolling and swinging integrated machine provided in the second embodiment, the electric control box includes the MCU main control module, the encoder information module, the servo control information module and the step control information module, and the pillar mechanism Fixed distance sensor. In order to enable the operator to synchronously process the position information of each transmission roller and cloth roll, motor servo signal or step signal through this control method, so as to make the transmission process more stable and reliable, and ensure that the force on the cloth is balanced, further, the control method It includes the following steps: S1: When the rolling and swinging integrated machine is running, the encoder information module collects the current encoder position information and sends it to the MCU main control module in real time. After analyzing the receiving mode, the servo cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com