Anti-siphon valve and sanitary ware using same

An anti-siphon and valve shell technology, applied in the field of sanitary ware, can solve the problems of insufficient elasticity, easy aging, closed slits, etc., and achieve the effects of average deformation, not easy to fatigue, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

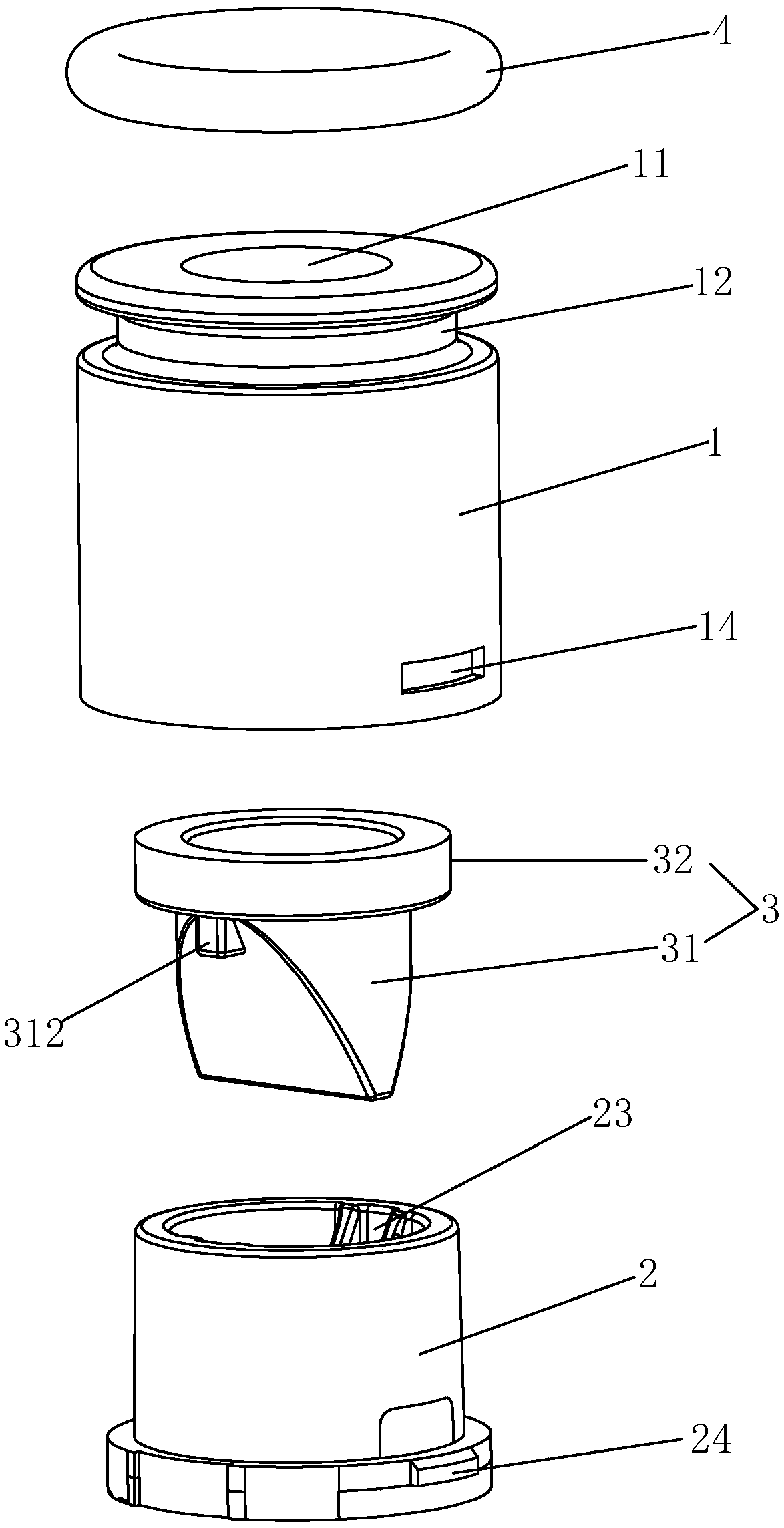

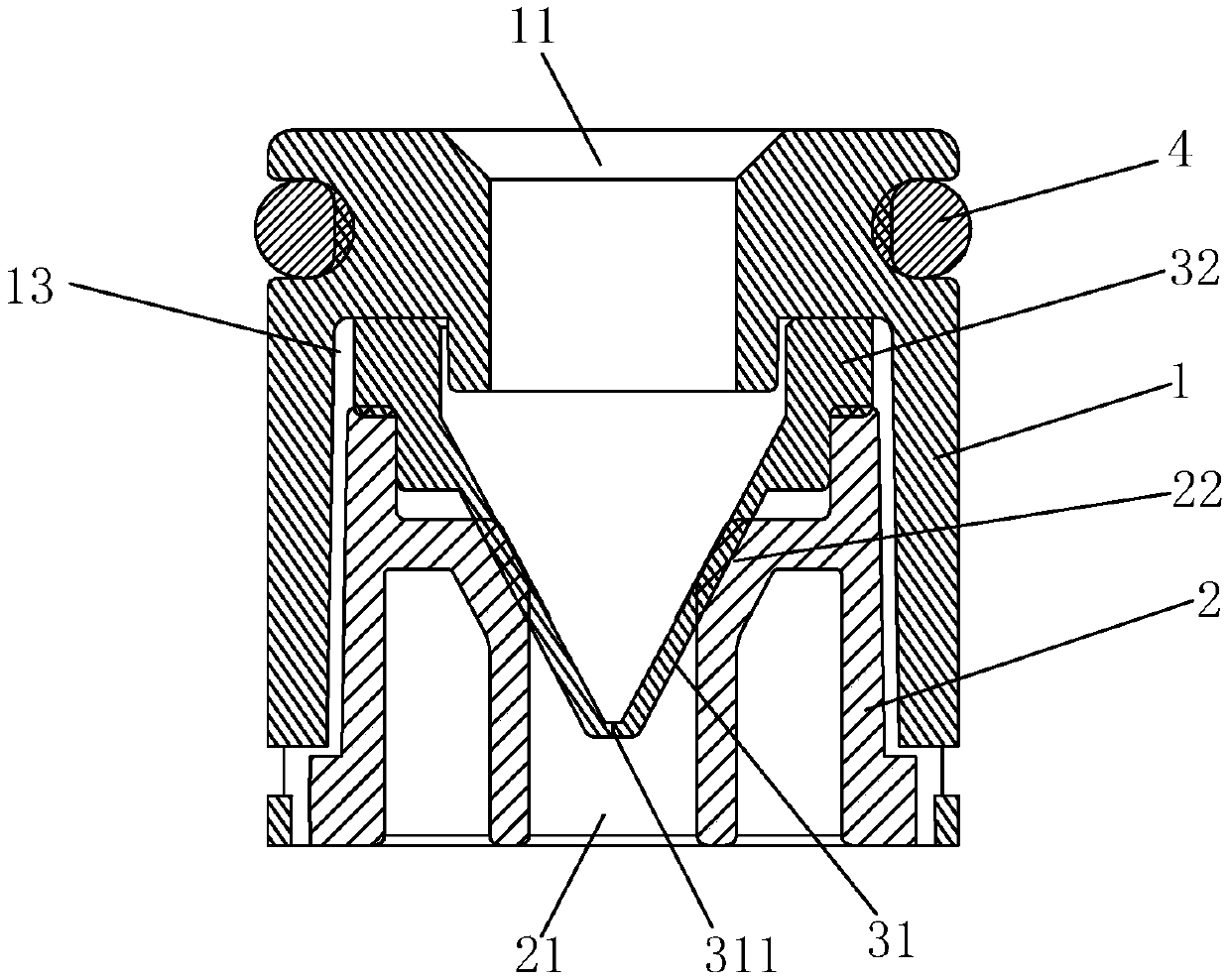

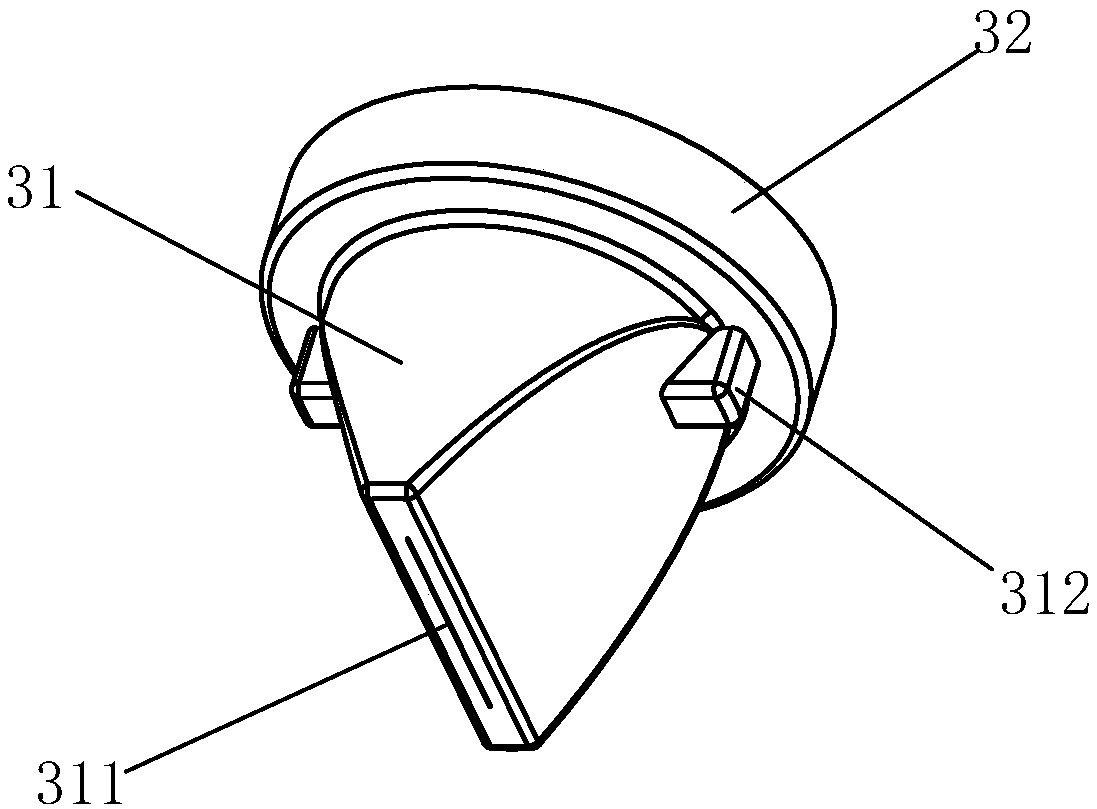

[0033] See Figure 1-Figure 5 As shown, an anti-siphon valve of the present invention includes a valve housing and a valve core 3. The two ends of the valve housing are respectively provided with a fluid inlet 11 and a fluid outlet 21. The valve core 3 is arranged in the valve cavity of the valve housing. The valve core 3 has a wedge-shaped deformation portion 31 facing the fluid outlet 21, and the tail end of the deformation portion 31 is provided with a slit 311 that can be opened and closed; the valve cavity of the valve housing is provided with two pre-compression structures, The two pre-compression structures pre-compress the outer surfaces of the two inclined walls of the deformation part 31 one by one, so that the deformation part 311 is deformed. The valve housing specifically includes an upper housing 1 provided with the fluid inlet 11 and a lower housing 2 provided with the fluid outlet 21 , the two are connected and matched to form the valve chamber. The pre-compre...

Embodiment 2

[0045] See Figure 8-Figure 13 As shown, an anti-siphon valve of the present invention differs from Embodiment 1 in that: the tail end of the deformation part 31 is provided with an extension part outwards, and the extension part includes two thin pieces 33, and the two thin pieces 33 are opposite to each other. Set and be located on both sides of the width direction of the slit, and the distance between the tail ends of the two sheets 33 is smaller than the width of the slit (in addition, the distance between the two sheets 33 can also be adapted to the width of the slit). The two sides of the two sheets 33 are connected one by one, but it is not limited thereto, and the two sheets 33 can also be separated from each other.

[0046] In this embodiment, the extension is in the shape of an inverted T (in addition, the extension can also be in the shape of an I), the valve housing is provided with two ribs 25, and the two ribs 25 are locked one by one. Inwardly recessed parts on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com