Detection method of fixed pressure vessel

A pressure vessel and detection method technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as unfixed pressure vessel judgment, and achieve the effect of accurate calculation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

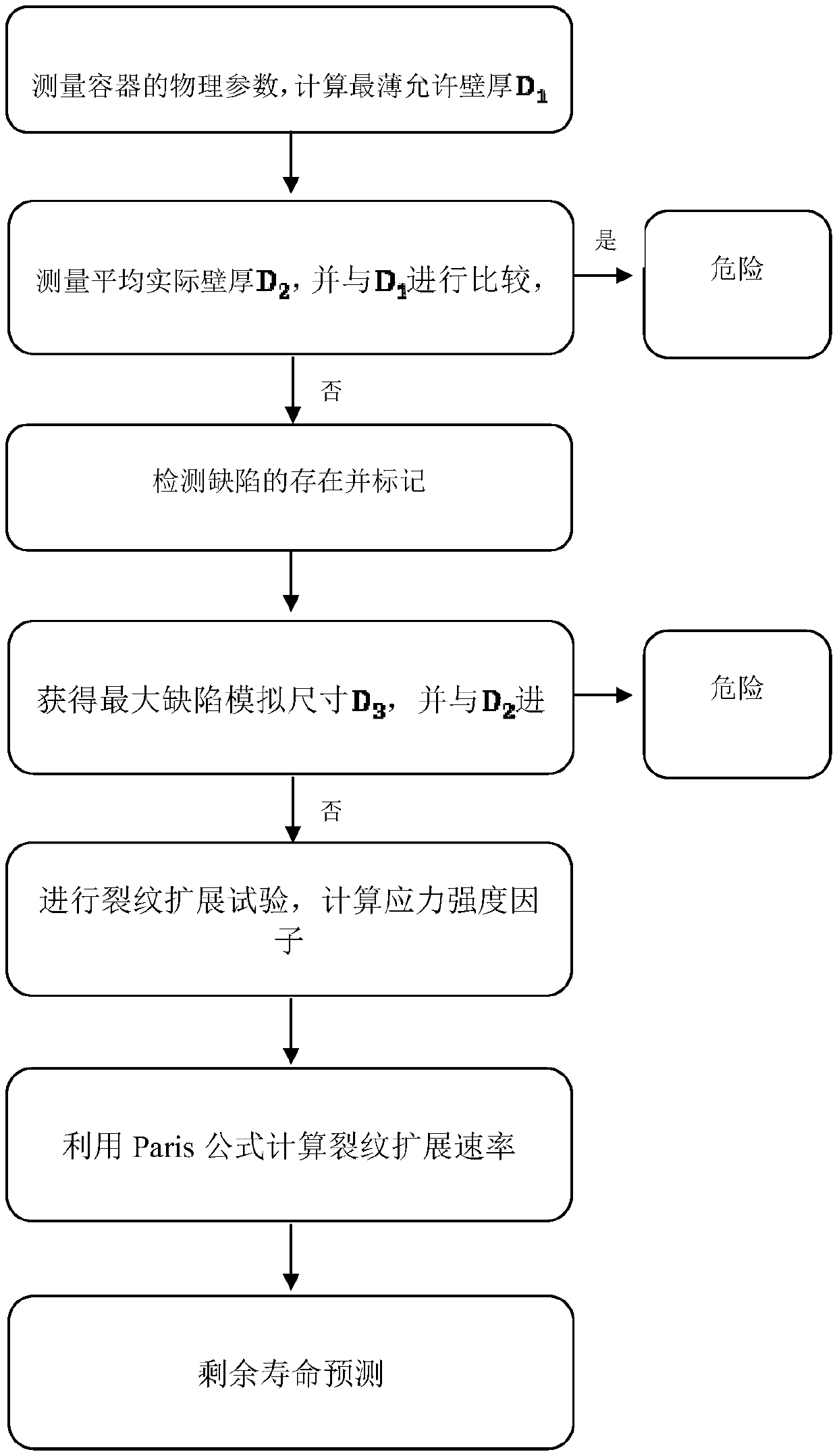

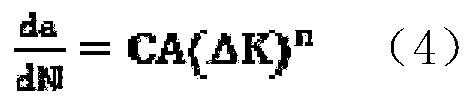

Method used

Image

Examples

Embodiment 1

[0045] For a petroleum storage tank made of 16MnR steel, its diameter is 7m, and the measured actual average wall thickness is 30mm. For detection, the specific steps are as follows:

[0046] Measure the inner diameter R of the pressure vessel, the allowable stress amplitude of the pressure vessel wall material at the service temperature and the weld coefficient α of the pressure vessel, use the formula (1) to calculate the theoretically thinnest allowable wall thickness of the pressure vessel:

[0047]

[0048] In the formula, D 1Indicates the theoretically thinnest allowable wall thickness of the pressure vessel, P is the maximum bearing pressure of the pressure vessel;

[0049] Substituting relevant parameters, the thinnest allowable wall thickness is 20.6mm. Since 20.6mm<0.8*30mm, proceed to step 3, scan the entire wall of the pressure vessel by ultrasonic measurement, determine existing defects, and locate all defects and mark it;

[0050] Step 4: Perform ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com