Thickness deviation-on-plate control method of cold-rolled sheet

A control method and technology for cold-rolled sheets, which are used in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problem of poor control effect, low yield, and can not fully reflect the length, width, and thickness of the entire strip. problems, to achieve the effect of small thickness fluctuation, good effect, accurate control strategy and calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

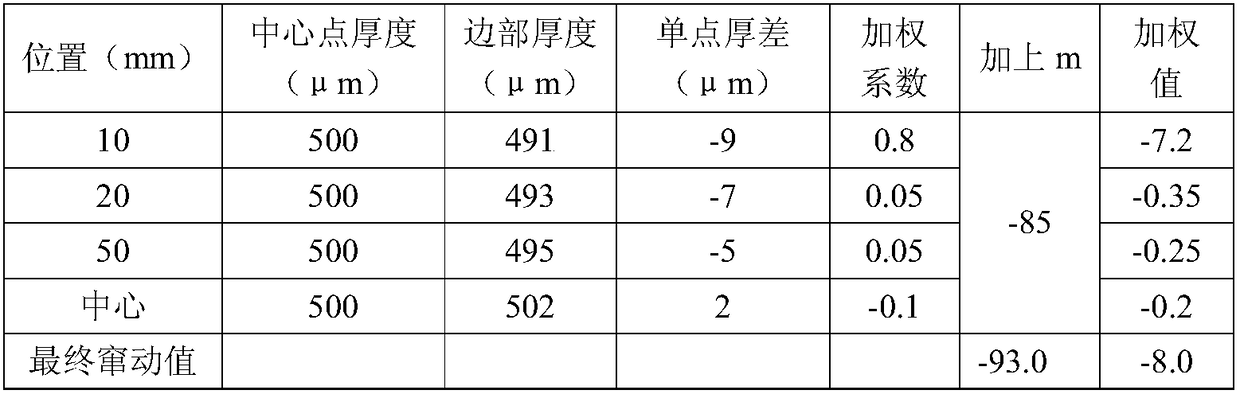

[0058] Taking a 5-stand tandem cold rolling mill as an example, the control method of the present invention is described in detail.

[0059] The thickness of the hot-rolled incoming material (center point) is 2.5mm, the thickness of the cold-rolled exit is 0.5mm, and the absolute thickness difference requirement of the exit edge (15mm from the edge) is 6μm.

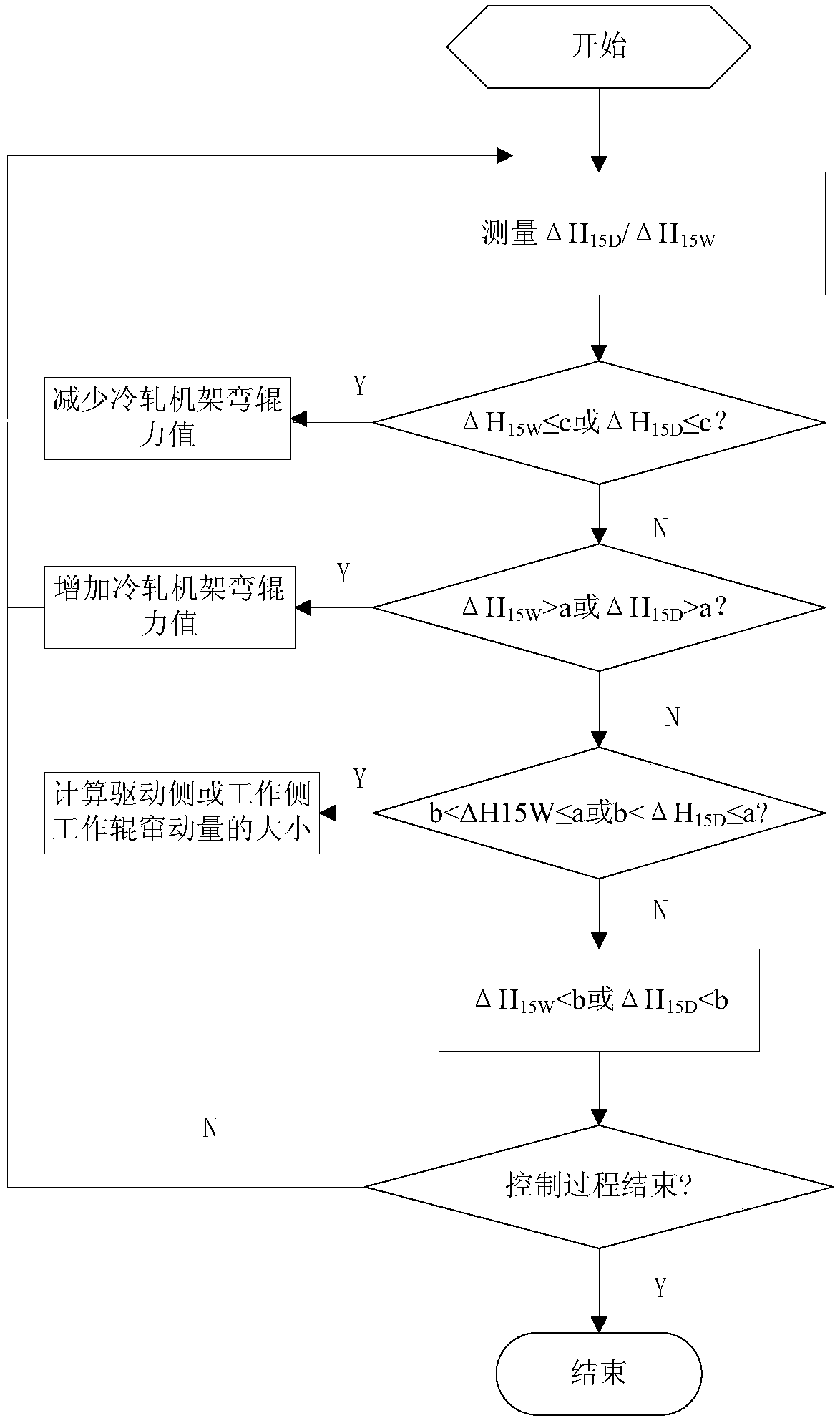

[0060] Determine whether the edge thickness difference is less than the parameter c (the value of parameter c is 1 μm), if the edge thickness difference of the driving side or the working side of the strip steel is less than the parameter c, immediately reduce the bending force value of the work roll of the rack (fixed value 2T) to ensure that the edge does not thicken, and the control process of this cycle is completed; if the thickness difference between the driving side and the working side is greater than the parameter c, enter the next parameter judgment;

[0061] Determine whether the thickness difference between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com