Lithium ion battery structure

A lithium-ion battery and current collector technology, which is applied in the field of power supply, can solve problems such as constraints and increase the risk of battery breakage, and achieve the effects of improved infiltration efficiency, less peeling off, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only for illustration and are not intended to limit the present invention. The present invention will be further described in detail below in conjunction with the accompanying drawings.

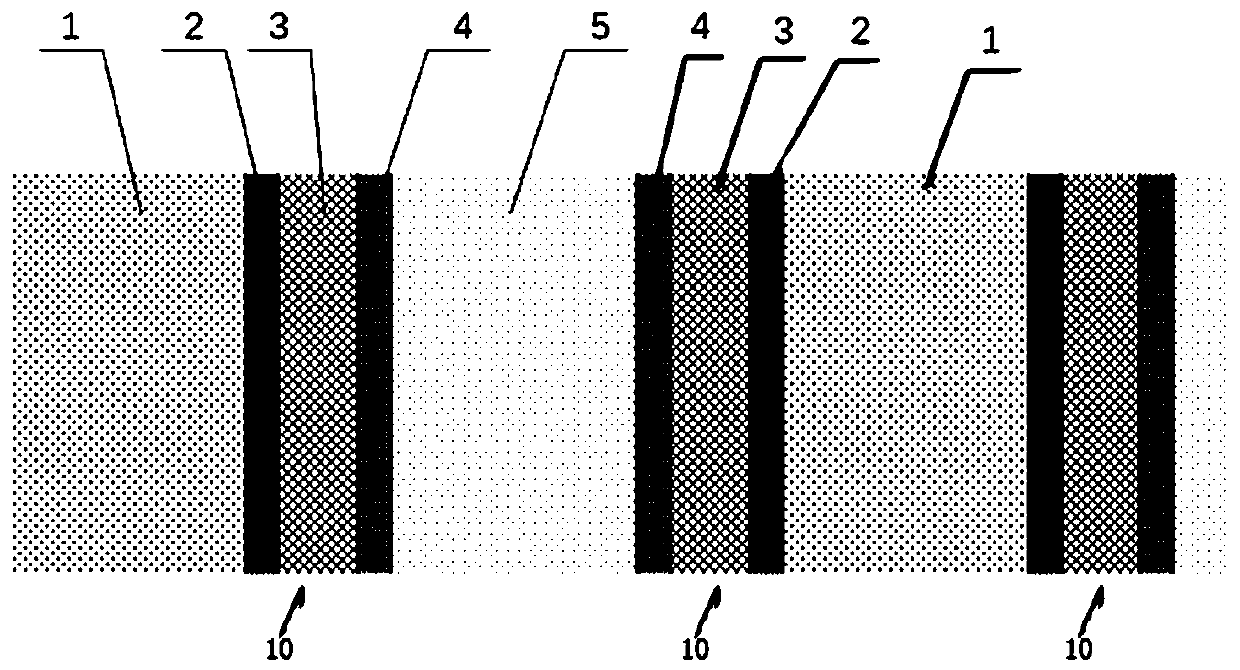

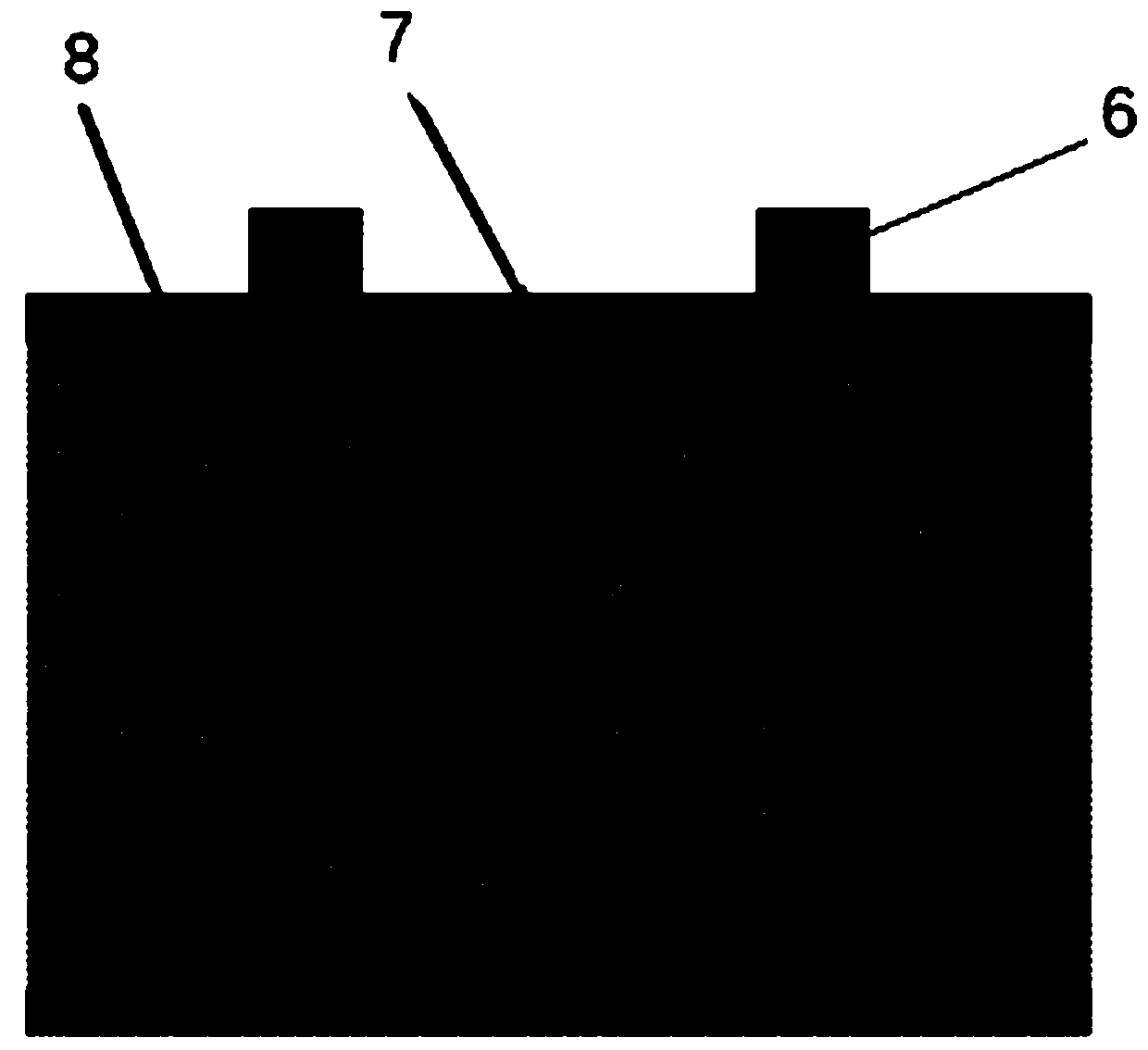

[0023] see figure 1 , the present invention proposes a lithium-ion battery structure, including porous aluminum foil 2 and porous copper foil 4 as positive and negative current collectors respectively covering the surfaces of both sides of the porous diaphragm 3 to form a current collector-diaphragm composite 10, the current collector-diaphragm The overall pores of the complex are connected. One end of the positive tab and the negative tab are respectively connected to the aluminum foil 2 and the copper foil 4 on both sides of the current collector-diaphragm composite. The current collector-diaphragm composite separates the positive electrode active material coating 1 and the negative electrode active material c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com