A method for breaking and threading a belt

A strip threading and strip breaking technology, which is applied to metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of strip steel rolling leakage, mandrel coiling is not tight, easy to produce scrap steel coils, etc., to reduce Effect of rolling waste, reduction of rolling waste, and improvement of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

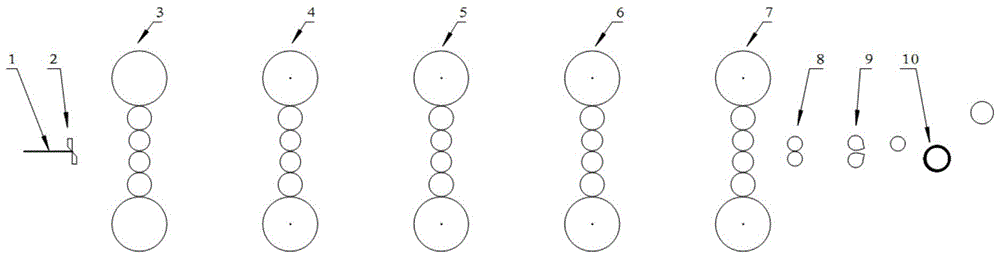

[0031] see figure 2 , the embodiment of the present invention provides a broken belt threading method, comprising the following steps:

[0032] Step 201: The rolling mill includes a first stand 3, a second stand 4, a third stand 5, a fourth stand, and a fifth stand 7, wherein the fifth stand 7 of the rolling mill needs to be broken to replace the backup roll. Adjust the shearing and coiling speed of the steel coil to be stopped and the previous steel coil to the minimum speed of 60m / min, and the flying shears are cut and coiled by 9, so that the position of the parking strip is controlled by reducing the shearing speed of the flying shears. Avoid taking the lead into the mandrel and affecting the reversing;

[0033] Step 202: After the shearing action is completed, press the normal stop button of the rolling mill to stop. Then manually jog the coiler 10 to coil the strip steel and unload the coil, lift all the racks and roll the roll gap;

[0034] Step 203: Select the fift...

Embodiment 2

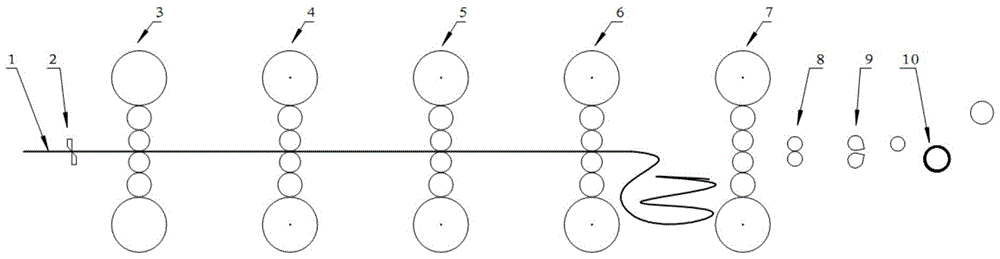

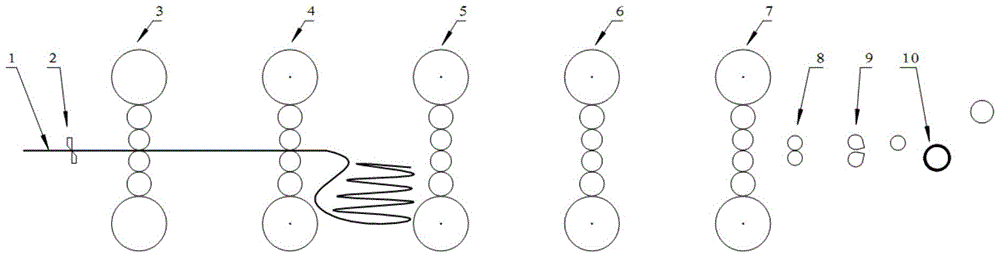

[0039] see image 3 , the embodiment of the present invention provides a broken belt threading method, comprising the following steps:

[0040] Step 301: The rolling mill includes a first stand 3, a second stand 4, a third stand 5, a fourth stand, and a fifth stand 7, wherein the third stand 5 of the rolling mill needs to be broken to replace the backup roll. Adjust the shearing and coiling speed of the steel coil to be stopped and the previous steel coil to the minimum speed of 60m / min, and the flying shears are cut and coiled by 9, so that the position of the parking strip is controlled by reducing the shearing speed of the flying shears. Avoid taking the lead into the mandrel and affecting the reversing;

[0041] Step 302: After the shearing action is completed, press the normal stop button of the rolling mill to stop. Then manually jog the coiler 10 to coil the strip steel and unload the coil, lift all the racks and roll the roll gap;

[0042] Step 303: Select the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com