Heat treatment process for induction quenching scanning of bearing without soft belt starting area

A technology of induction hardening and induction heater, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of reduced induction heating effect, impact on bearing fatigue life, uneven stress distribution, etc. Increased service life and small fluctuations in hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

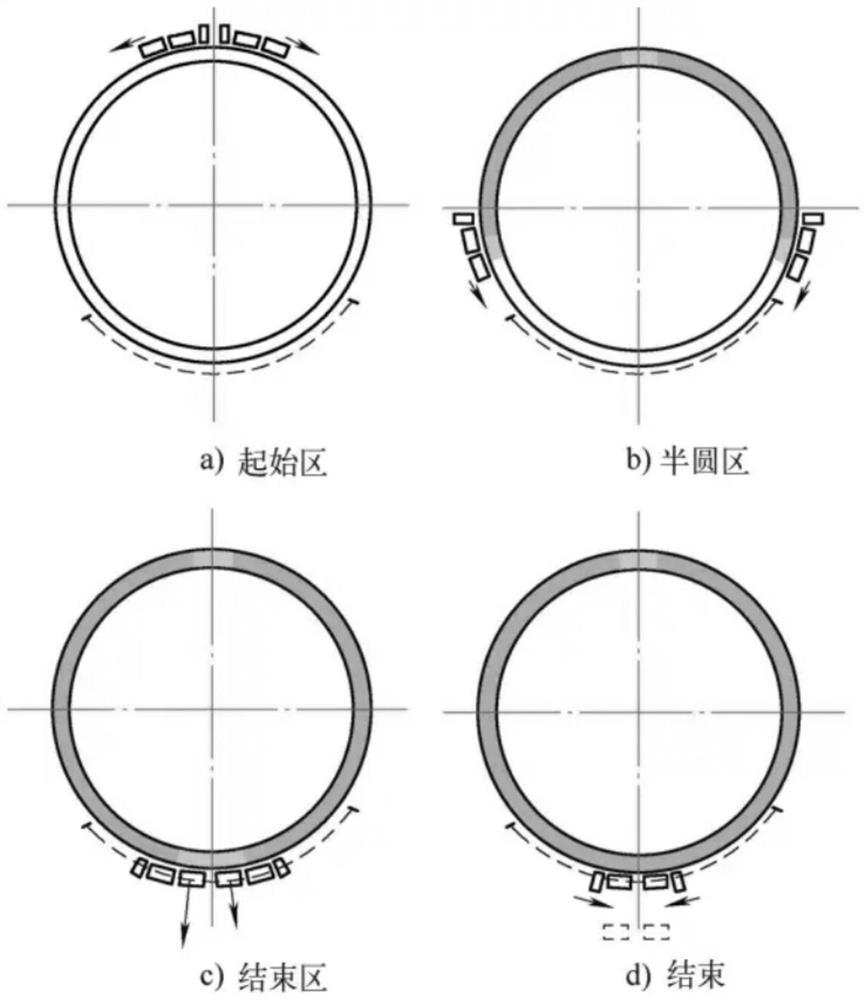

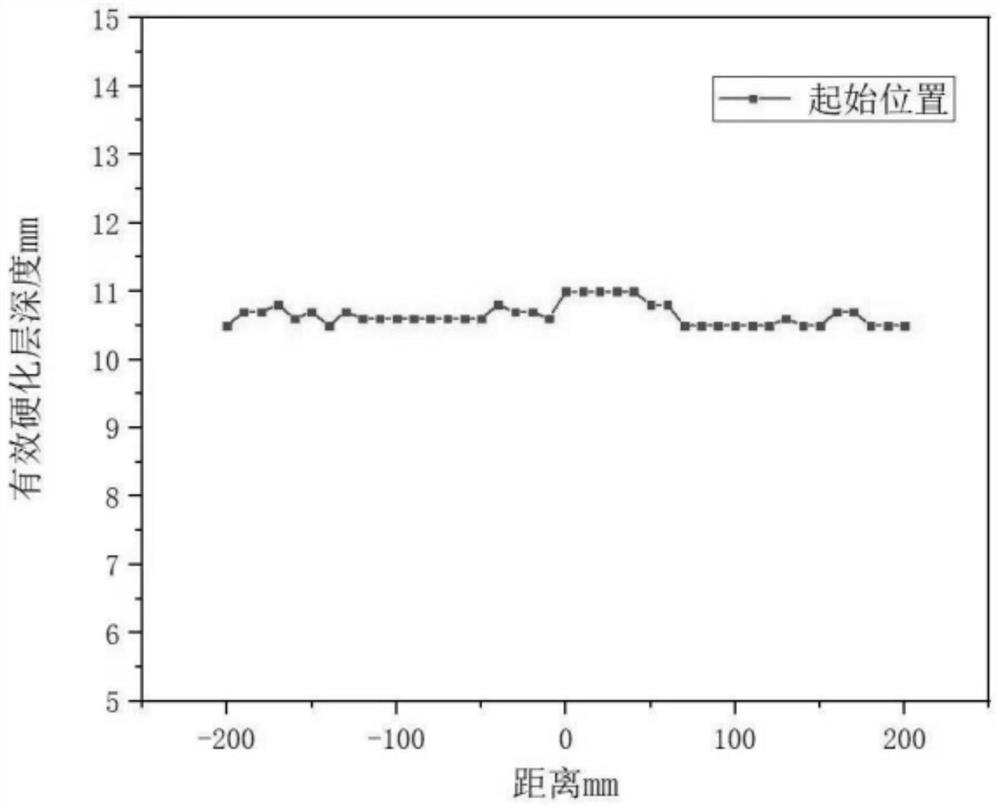

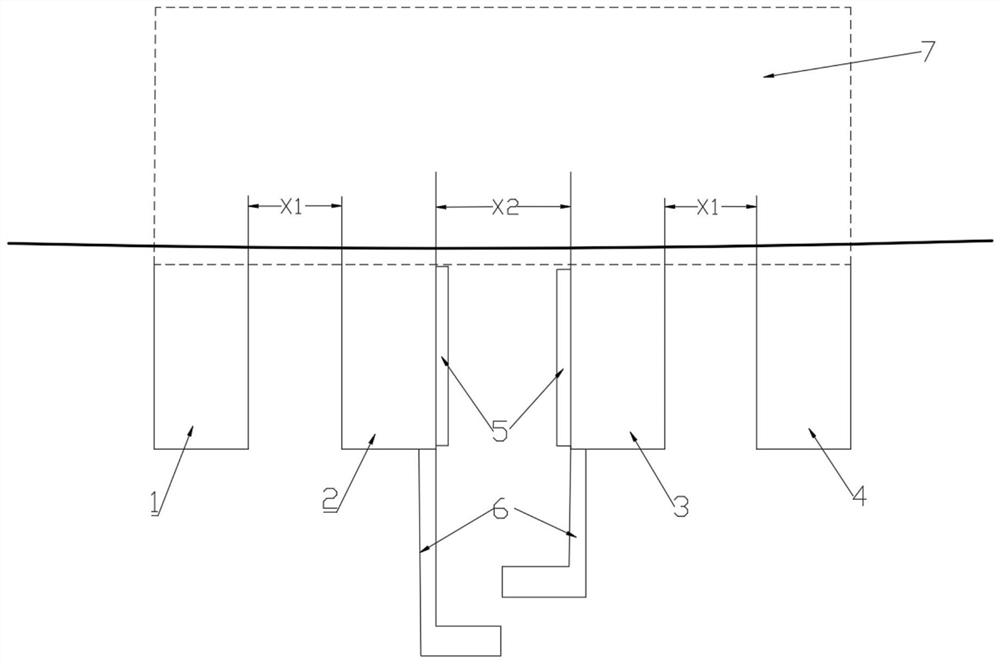

[0045] like figure 2 , image 3 As shown in the figure, a heat treatment process for induction quenching scanning without soft belt starting area specifically applied to the main bearing of wind power, including No. 1 heating assembly and No. 2 heating assembly, each group of heating assemblies includes two inductors, specifically: No. 1 heating assembly The heating assembly includes a first induction preheater and a first induction heater, and the second heating assembly includes a second induction preheater and a second induction heater. At the starting area, the two heating assemblies are close together, and the four induction heaters are The relative positions of the heaters are the first induction heater, the first induction heater, the second induction heater, and the second induction heater. The first induction heater and the second induction heater are provided with a main sprayer and an auxiliary sprayer that can be started and stopped independently. The main spraye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com