A kind of mechanochromic polymer material containing phenolphthalein derivative with fast self-recovery property and preparation method thereof

A polymer material and color-induced technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

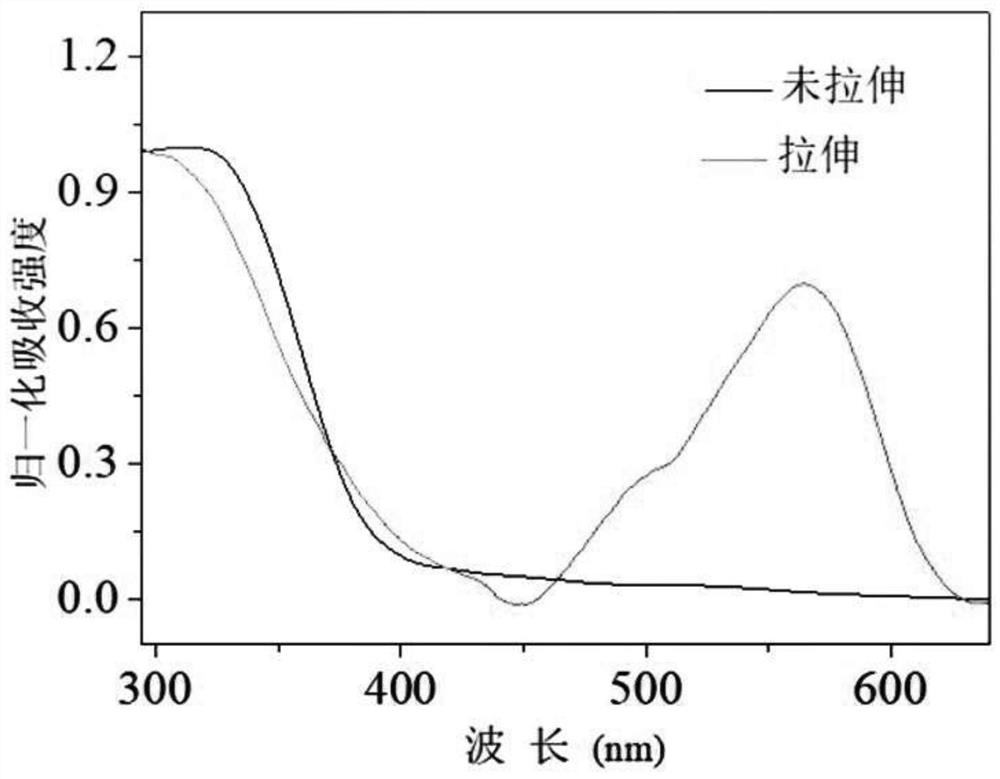

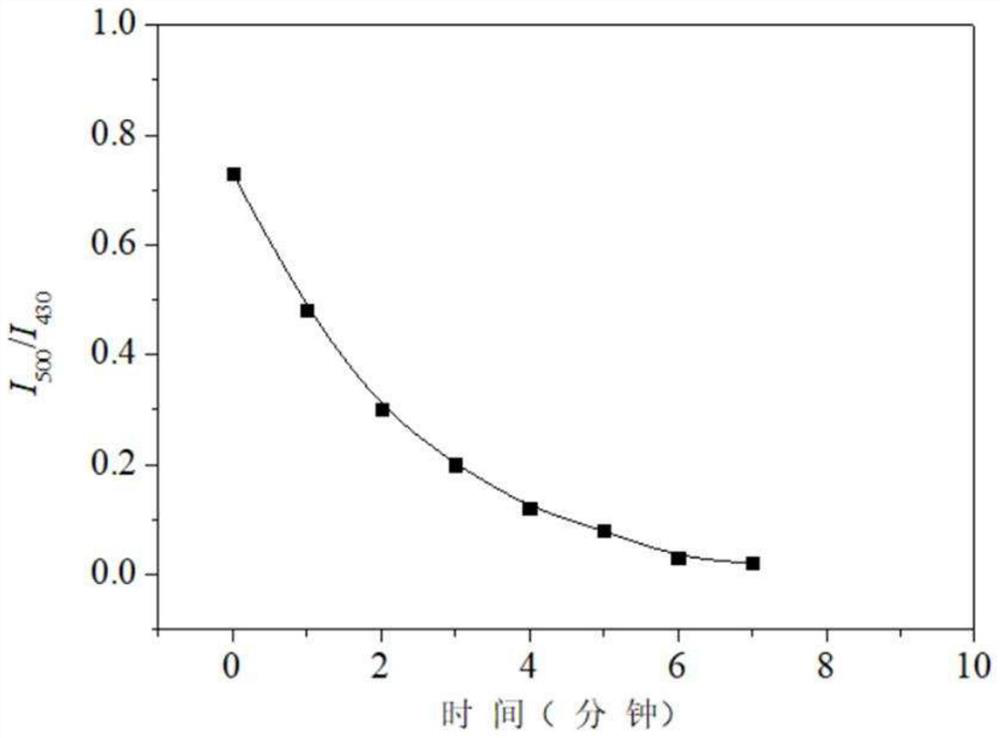

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

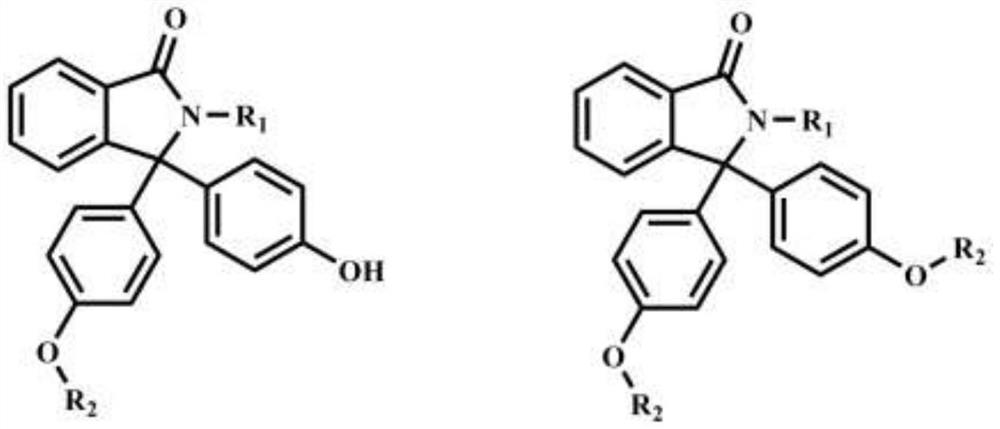

[0030] Example 1: Preparation of Mechanochromic Polymer Material 1

[0031] The preparation route is as follows:

[0032]

[0033] Concrete preparation steps are as follows:

[0034] a) Phenolphthalein (10mmol) was dissolved in 40mL of ethanol, ethanolamine (30mmol) was added to the above system, the system was refluxed and stirred for 24, and the solvent was distilled off under reduced pressure, and the crude product was separated and purified through silica gel chromatography (developing agent was dichloromethane / methanol=5 / 1) to obtain P-1. The yield was 90%. 1 H NMR (400MHz, CDCl 3 ):7.91(d,1H),7.58(m,1H),7.18(m,1H),7.03-7.08(m,5H),6.63(m,4H),5.30(s,2H),3.65(t, 2H), 3.61(s, 1H), 3.30(t, 2H).

[0035] b) Add P-1 (8mmol), anhydrous potassium carbonate (16mmol), bromoethanol (1.5mmol) into the solvent acetone. The reaction system was stirred overnight at 90° C. after freezing-vacuumizing-nitrogen three times. After the reaction was completed, the system was poured ...

Embodiment 2

[0037] Example 2: Preparation of Mechanochromic Polymer Material 2

[0038] The specific preparation steps are as follows: the same part (steps a and b) as in Example 1 will not be repeated, and the difference with Example 1 is that

[0039]Step c): P-2 (0.8 mmol) and di-tert-butyltin dilaurate (0.14 mmol) were dissolved in hexamethylene diisocyanate (1.4 mmol), and the system was stirred and reacted at 40°C. After 1 hour, dry polytetrahydrofuran (M n =2000g / mol, 2mmol) and anhydrous tetrahydrofuran (5mL) and continued stirring at 40°C for 2 hours. Then, the remaining hexamethylene diisocyanate (1.4 mmol) was slowly added into the solution and the stirring was continued at 40° C. for 3 hours, and finally the polymer was precipitated by methanol to obtain the lyrochromic polymer material 2 .

Embodiment 3

[0040] Example 3: Preparation of Mechanochromic Polymer Material 3

[0041] The preparation route is as follows:

[0042]

[0043] Concrete preparation steps are as follows: its identical part (step a) with embodiment 1 repeats no more, and the difference with embodiment 2 is in step:

[0044] b) Add P-1 (8mmol), anhydrous potassium carbonate (16mmol), bromoethanol (2.0mmol) into the solvent acetone. The reaction system was stirred overnight at 90° C. after freezing-vacuumizing-nitrogen three times. After the reaction was completed, the system was poured into water and extracted three times with chloroform. The organic phase was dried over anhydrous sodium sulfate, and the solvent was distilled off under reduced pressure. The crude product was separated and purified by silica gel column chromatography (gradient elution with n-hexane / ethyl acetate eluent from 1:0 to 1000:5) to obtain the target product P-3. The yield was 75%. 1 H NMR (400MHz, CDCl 3 ):7.91(1H,d),7.58(1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com