Knitting method of flat knitting machine with tatting effect

A woven and knitting technology, applied in knitting, weft knitting, textiles and papermaking, etc., to achieve the effect of good structural strength, good air permeability and beautiful fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

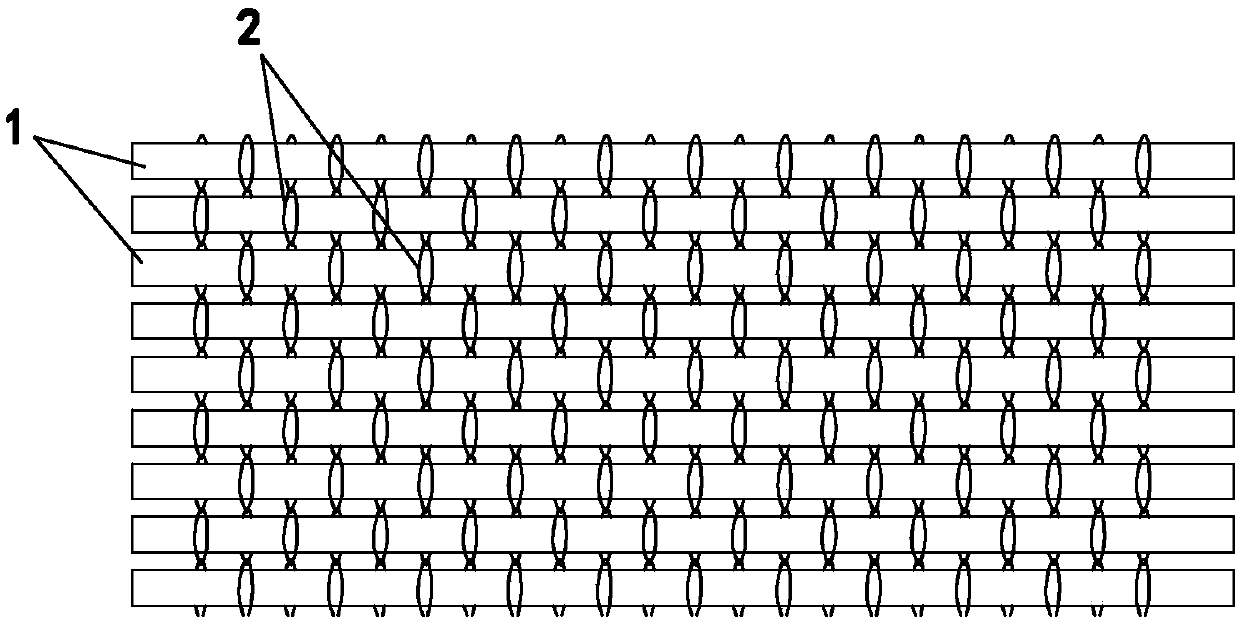

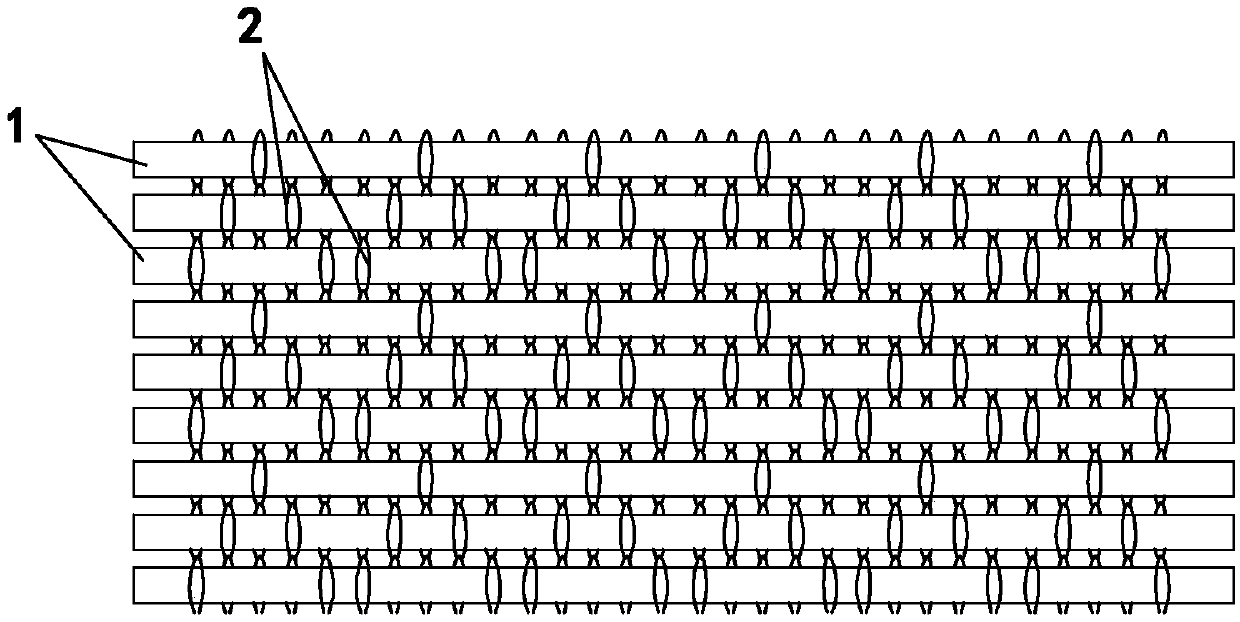

[0017] The invention discloses a flat knitting method with a weaving effect, the structure of the weaving effect is as figure 1 and figure 2 As shown, it includes imitation weft 1 and imitation warp 2, specifically computerized flat knitting machine knitting, at least one yarn feeder of the computerized flat knitting machine is provided with imitation weft 1, and at least one yarn feeder is provided with imitation warp 2, according to the design if There are threads of different colors and materials, and multiple yarn feeders can be used. Using multiple yarn feeders at the same time can also improve the knitting efficiency of fabric formation. In order to make the weaving effect of knitting more obviously similar, the The thread thickness of imitation weft thread 1 is greater than that of imitation warp threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com