Safety plug

A technology of safety plugs and shells, which is applied in the direction of contact parts, electrical components, and devices to prevent contact with live contacts, etc., which can solve the problems of unsafe plugs and easy loosening, so as to avoid heating and short circuits, stabilize response temperature, and avoid overheating too high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

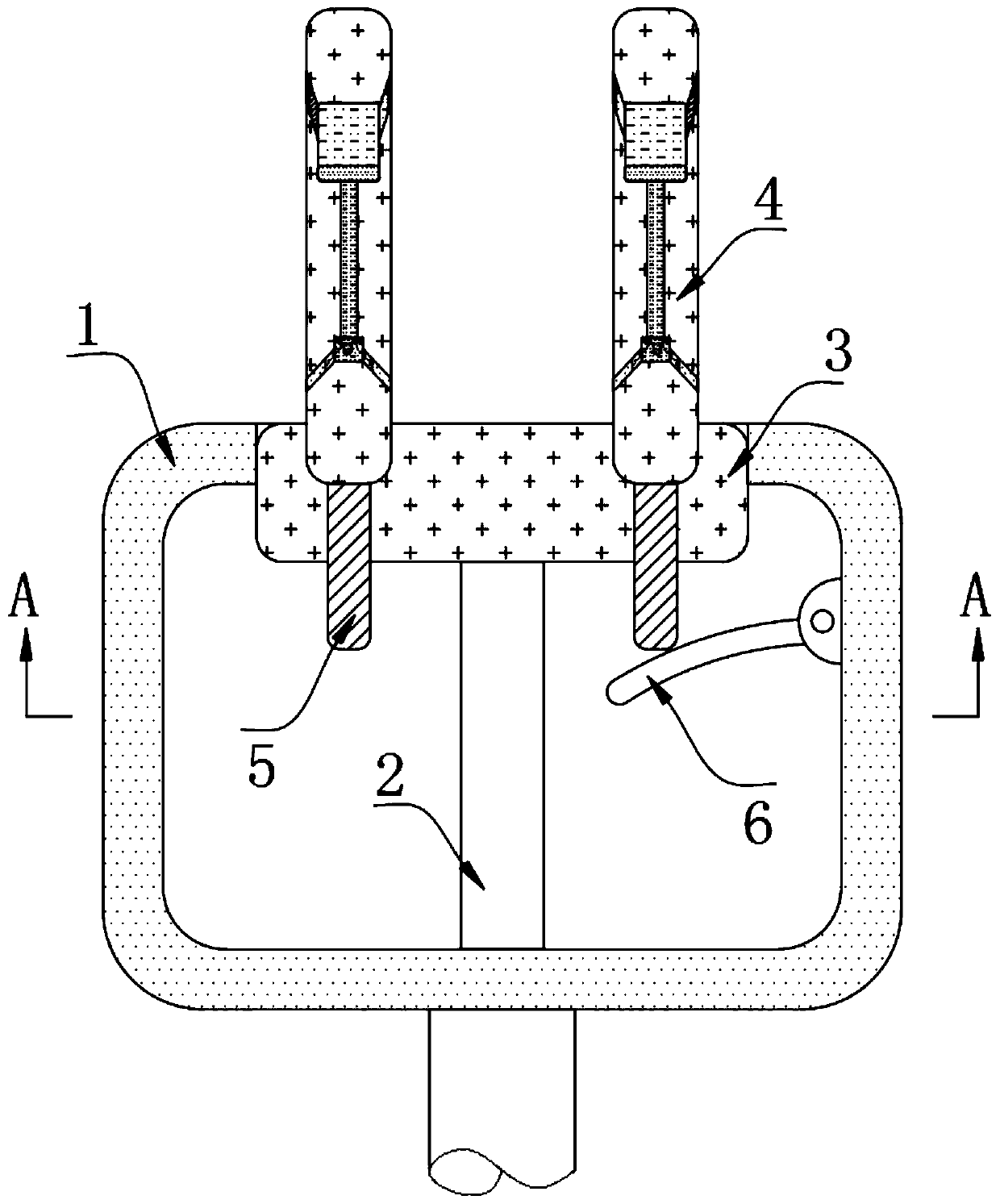

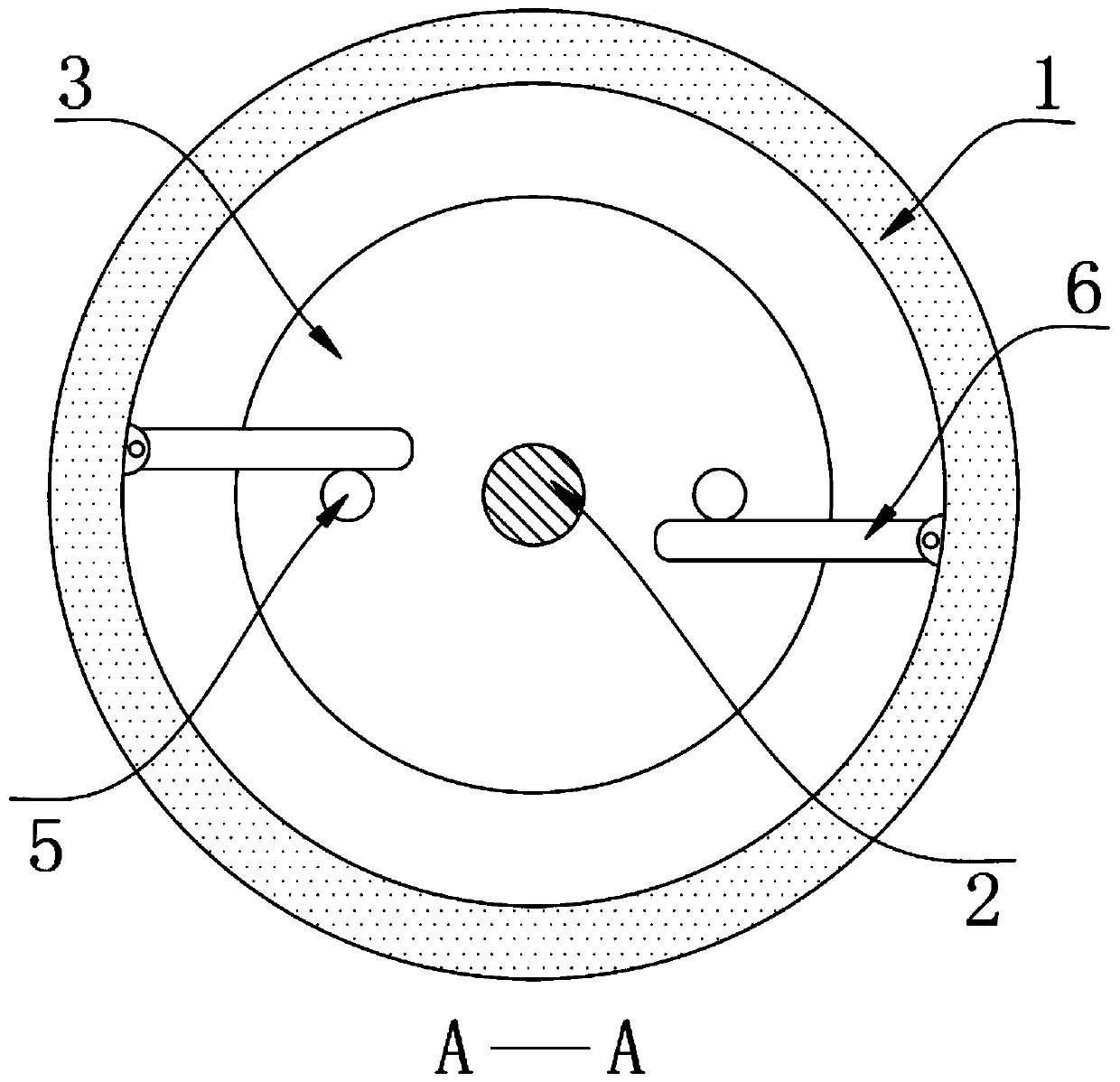

[0021] Reference Figure 1-3 , A safety plug includes a housing 1. The inner wall of the housing 1 is rotatably connected with a rotating shaft 2 through a torsion spring. The upper end of the rotating shaft 2 is fixed with a turntable 3, and the turntable 3 is connected to the side wall of the housing 1 for rotation. The upper end of the turntable 3 is inserted There are two symmetrical connection posts 4, and the inside of the two connection posts 4 is equipped with an anti-drop mechanism. The ends of the two connection posts 4 close to the rotating shaft 2 are fixed with a conductive post 5 that penetrates the turntable 3, and the housing 1 The inner wall is rotatably connected with the power-off poles 6 which are opposed to the two conductive poles 5 through a torsion spring.

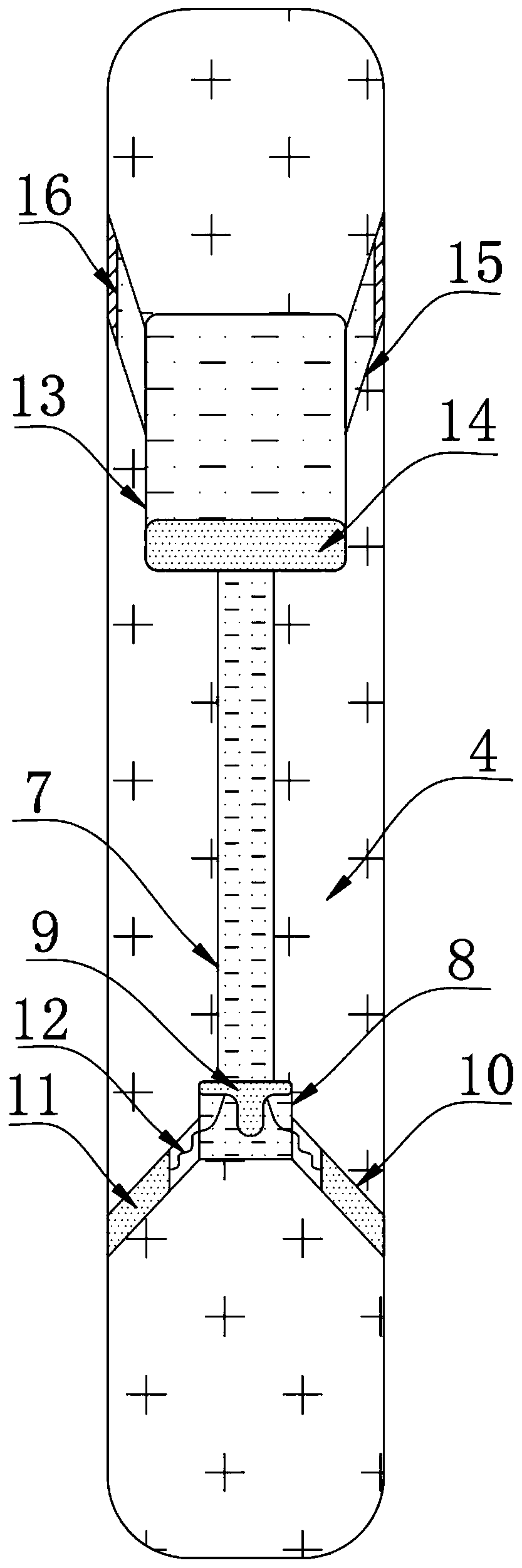

[0022] The anti-dropping mechanism includes an expansion cavity 7 opened inside the electrical connection column 4, and the expansion cavity 7 is provided with a retaining slot 8 on one side close to t...

Embodiment 2

[0029] Reference Figure 4 , A safety plug includes a housing 1, the inner wall of the housing 1 is rotatably connected with a shaft 2 through a torsion spring, the upper end of the shaft 2 is fixed with a turntable 3, the turntable 3 is rotatably connected with the side wall of the housing 1, and the upper end of the turntable 3 is inserted There are two symmetrical connection posts 4, and the inside of the two connection posts 4 is equipped with an anti-drop mechanism. The ends of the two connection posts 4 close to the shaft 2 are fixed with a conductive post 5 that penetrates the turntable 3, The inner wall is rotatably connected with the power cut-off pillars 6 that are opposed to the two conductive pillars 5 through a torsion spring.

[0030] The anti-dropping mechanism includes an expansion cavity 7 opened inside the electrical connection column 4, and the expansion cavity 7 is provided with a retaining slot 8 on one side close to the housing 1. The interior of the retainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com