Cable loading crane with automatic decimal alignment pressure-bearing and shearing resistance functions

A cable-mounted crane and automatic alignment technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as positioning and installation difficulties, and achieve the effect of easy operation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the drawings.

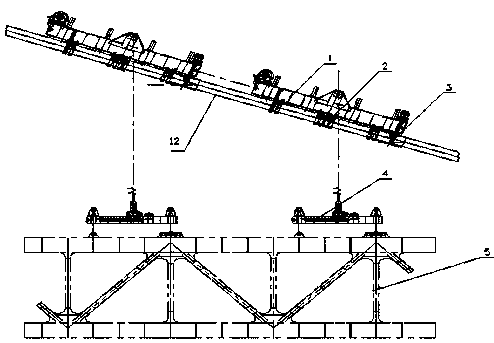

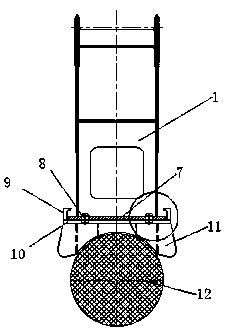

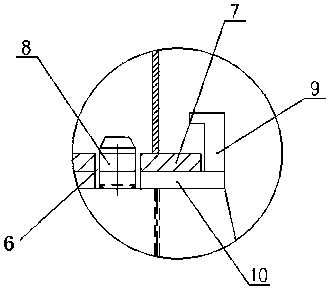

[0015] A cable-mounted crane with automatic alignment, compression and shear resistance, includes a spreader 4 connected with an end beam 1, and a heavy part 5 is fixed at the lower end of the spreader 4, such as Figure 1-Figure 4 As shown, the lower ends of the end beam 1 are provided with cable clamps 3, and the lower end of the end beam 1 is also provided with a plurality of pressure-bearing and shear-resistant blocks 2. The pressure-bearing and shear-resistant blocks 2 include a top plate 10, and the lower end of the top plate 10 The bottom plate 11 is fixed, the bottom end of the bottom plate 11 is provided with a main cable 12, and the main cable 12 is fixed to the lower end of the bottom plate 11 through a cable clamp 3. The four corners on the upper end surface of the top plate 10 are all provided with anti-hooks 9 and the upper end surface of the top plate 10 A pin 8 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com