Production process of hot-rolled steel plate

A hot-rolled steel plate and production process technology, applied in metal rolling and other directions, can solve the problems of poor stacking effect, inconvenient stacking, oxidation, etc., and achieve the effects of good cooling and heat dissipation, simple and convenient operation, and good stacking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

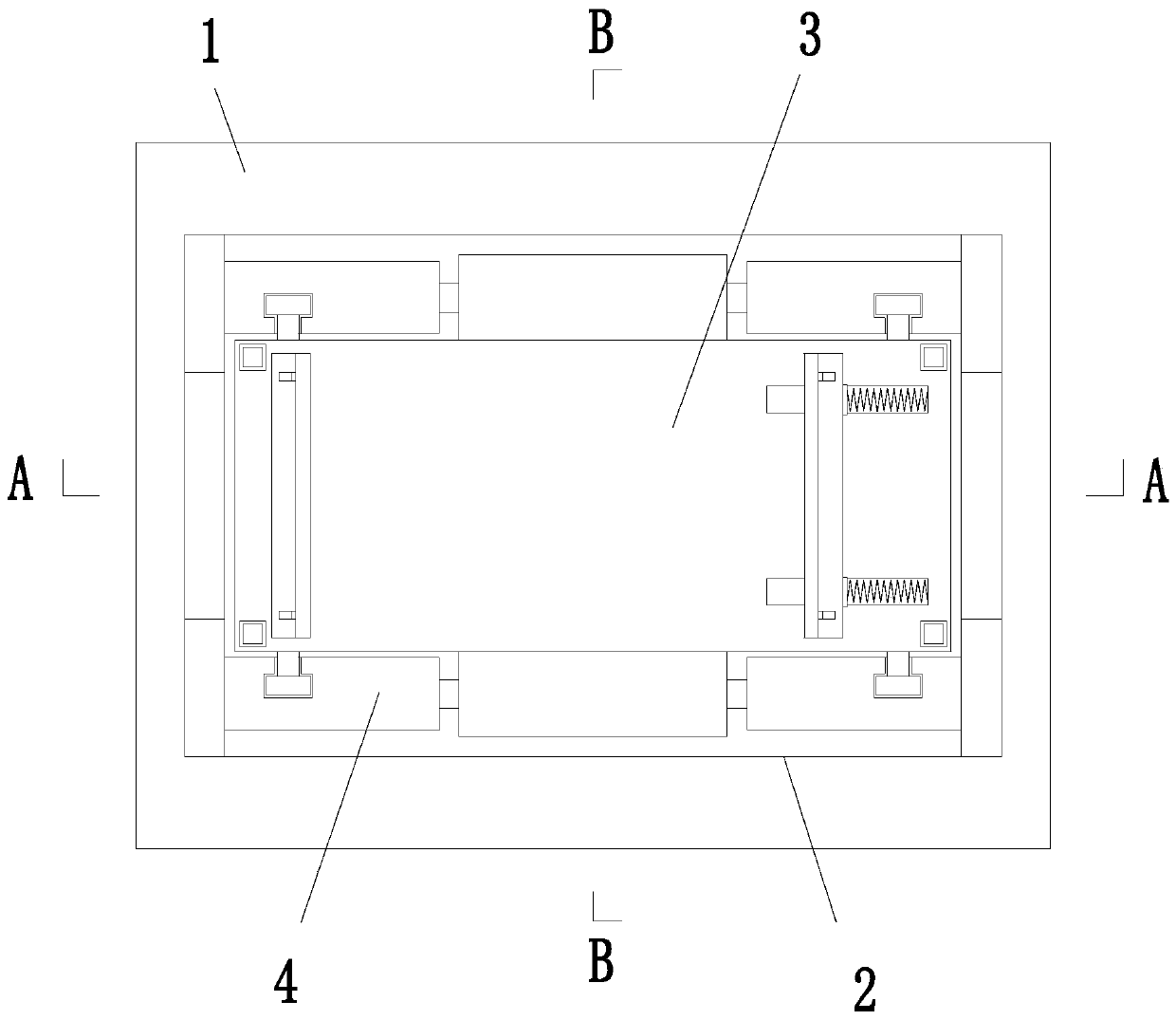

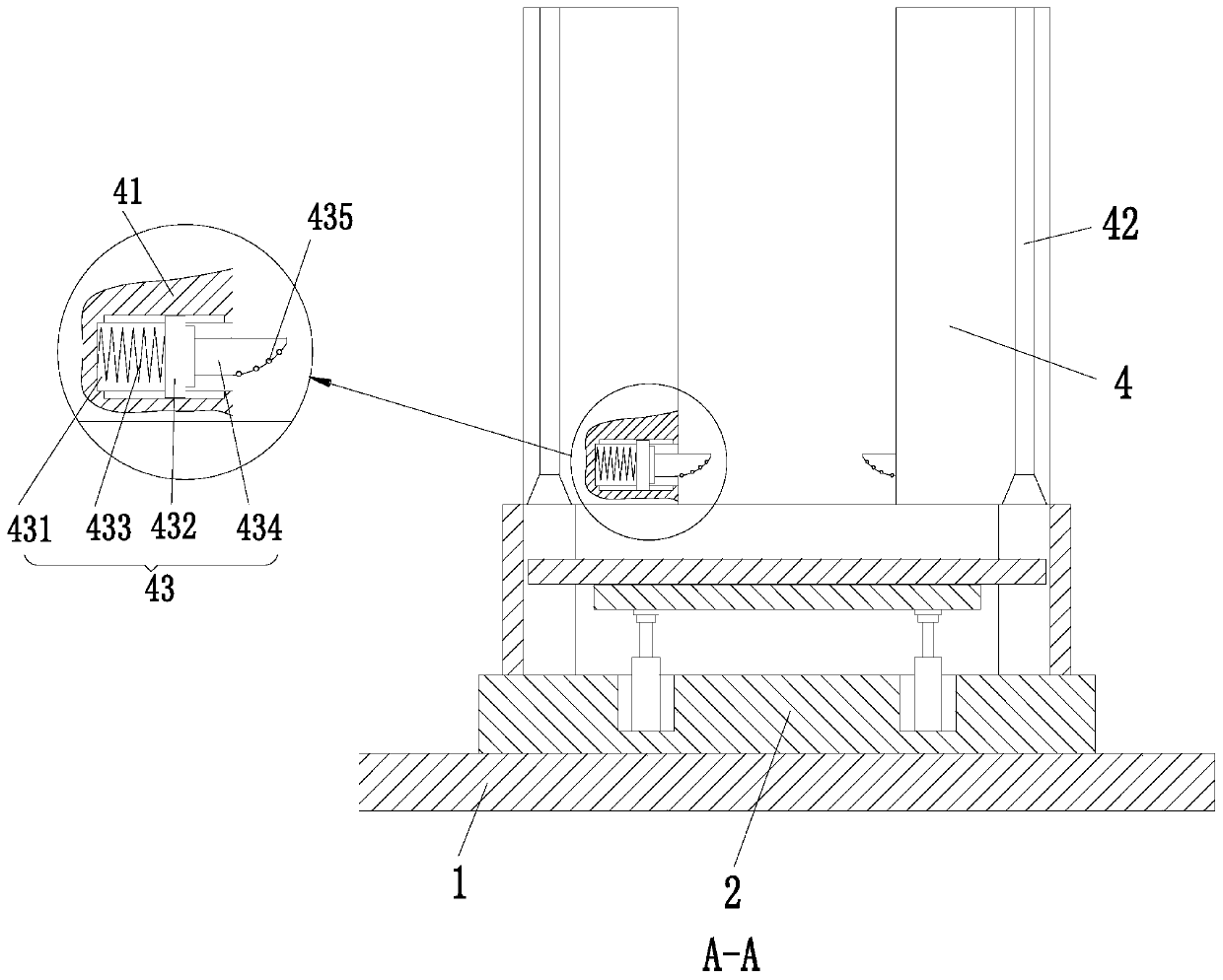

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

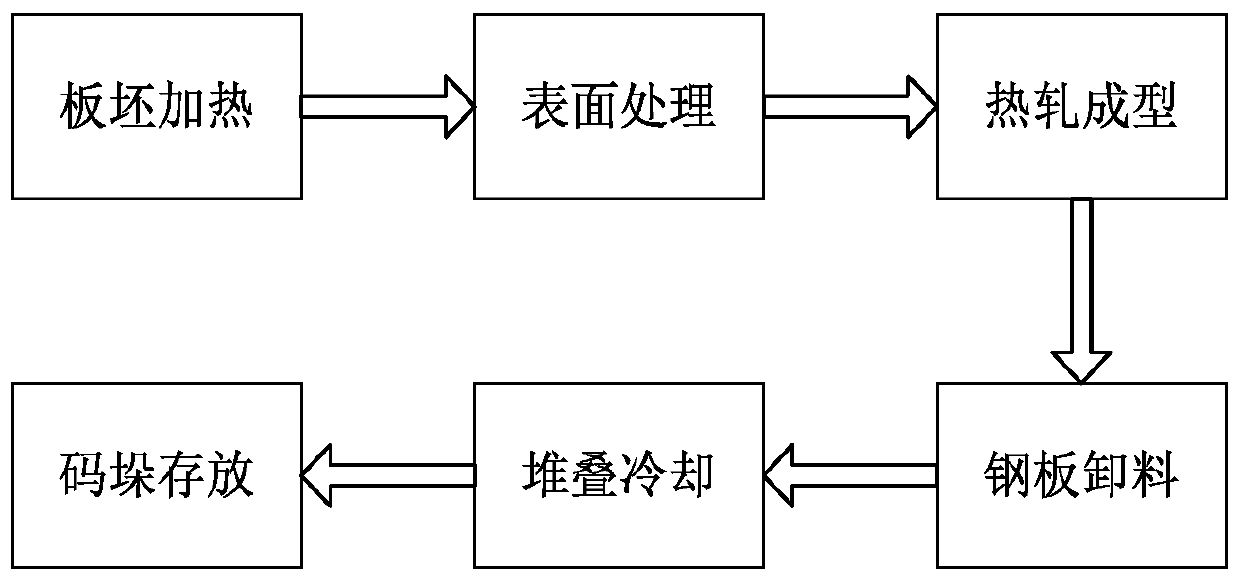

[0037] Such as Figure 1 to Figure 6 Shown, a kind of hot-rolled steel plate production process comprises the following steps:

[0038] S1. Slab heating: Manually send the steel plate slab to the inside of the furnace loading roller table for heating;

[0039] S2, surface treatment: the slab heated in step S1 is washed with high-pressure water to remove the iron oxide scale on the surface of the slab;

[0040] S3, hot-rolled forming: the slab processed in step S2 is sent to the hot-rolling mill to be rolled into a hot-rolled steel plate;

[0041] S4, steel plate unloading: place the hot-rolled steel plate after hot-rolling in step S3 on the supporting bracket through the slab clamp;

[0042] S5, stacking and cooling: manually put the supporting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com