A Simple Steel Pipe Pile Support Heap Load Preloading Structure and Method

A technology of stacking preloading and steel pipe piles, which can be used in the erection/assembly of bridges, buildings, bridge construction, etc., and can solve problems such as less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

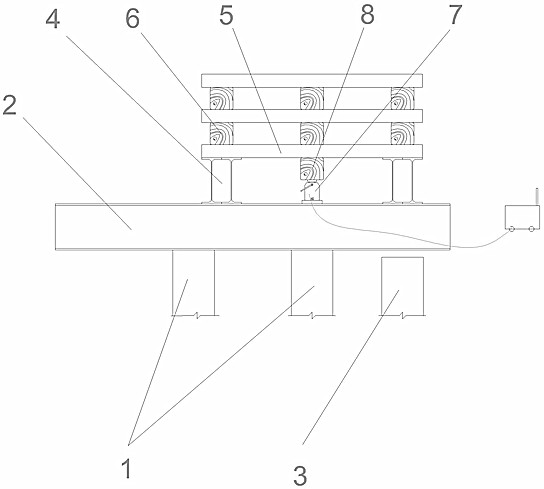

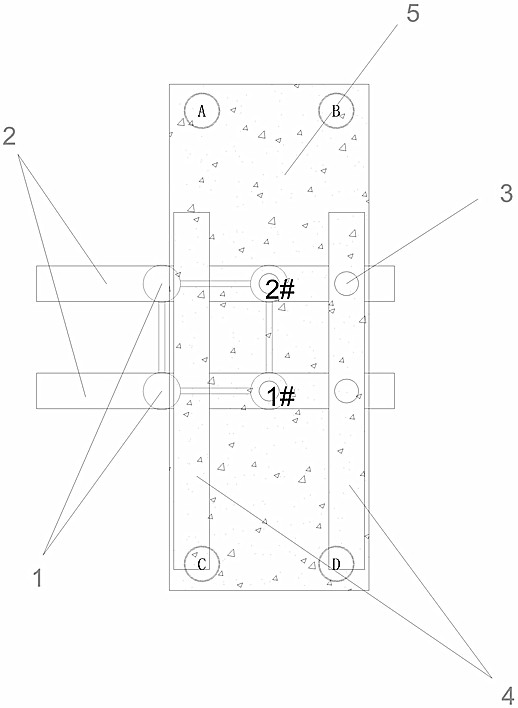

[0014] The specific embodiment of the present invention will be described below in conjunction with accompanying drawing, as figure 1 , figure 2 Shown: a simple steel pipe pile support preloaded preloading structure, which includes four prefabricated concrete piles 1, the four prefabricated concrete piles 1 are respectively distributed at the four vertices of a square, these four prefabricated concrete piles The piles 1 are divided into two pairs, each pair of prefabricated concrete piles is supported by a steel beam 2, and an anti-overturning pile 3 is arranged under the steel beam 2, and a steel beam 2 is jointly supported on the two steel beams 2. For the I-beams 4 parallel to each other, and the I-beams 4 and the steel beams 2 are perpendicular to each other, the top of the pair of I-beams 4 is jointly supported by a first layer of prefabricated slabs 5, the first layer The first layer of sleepers 6 is arranged above the prefabricated slab 5, and the second layer of pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com