Vacuum conducting ring abrasive dust imaging monitoring device

A technology for monitoring devices and conductive rings, which can be used in measuring devices, televisions, electrical components, etc., and can solve problems such as electrification of conductive ring wear debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

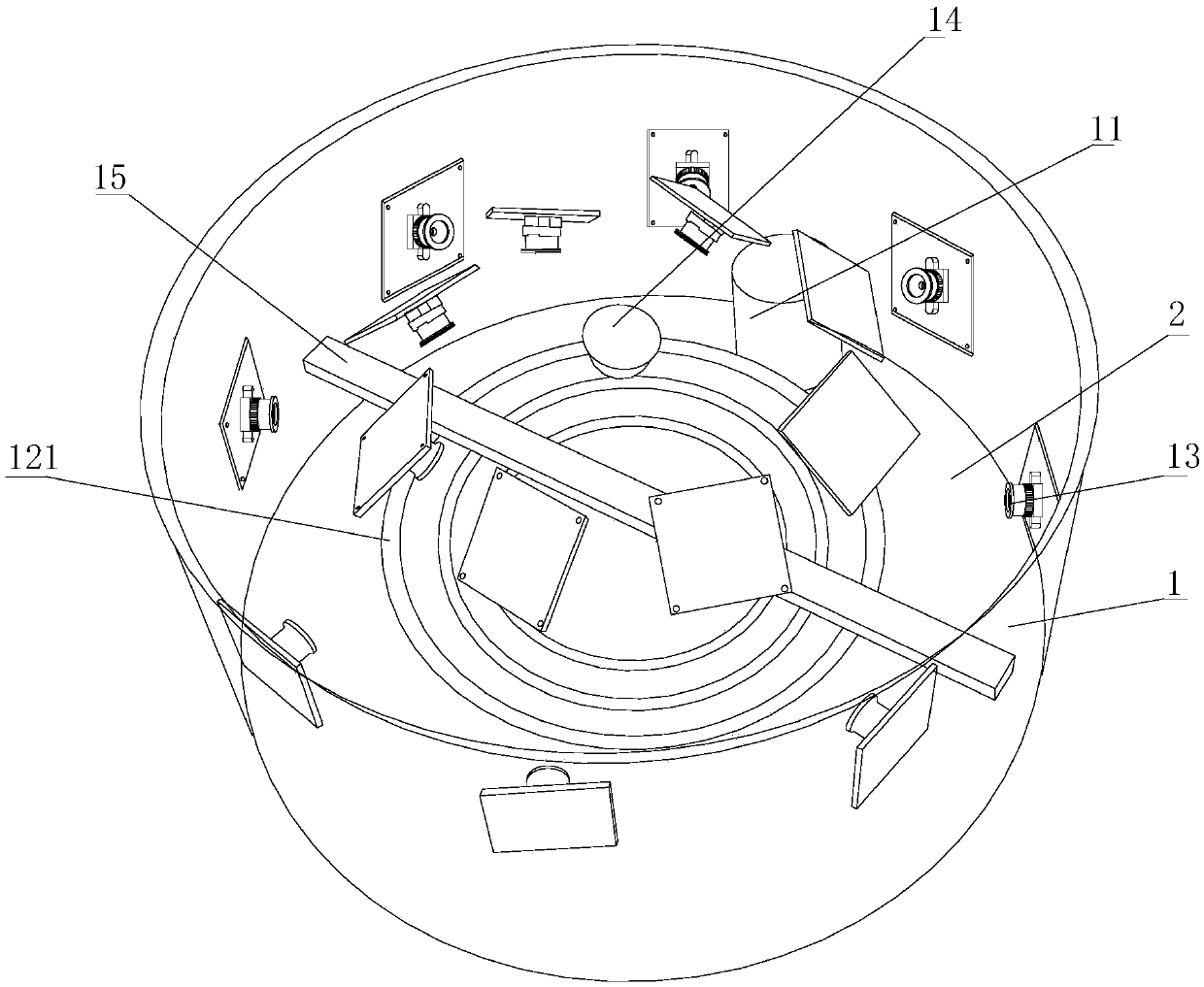

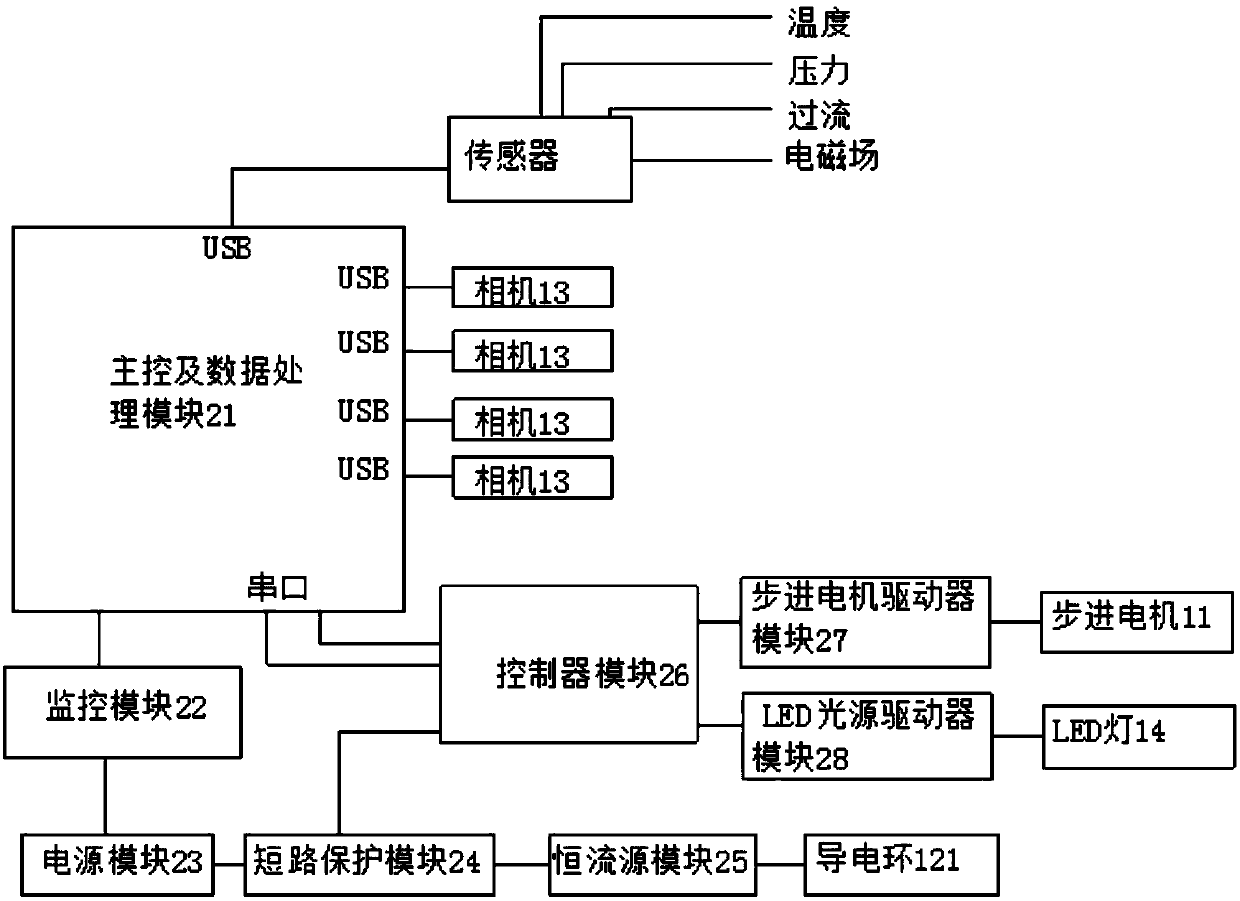

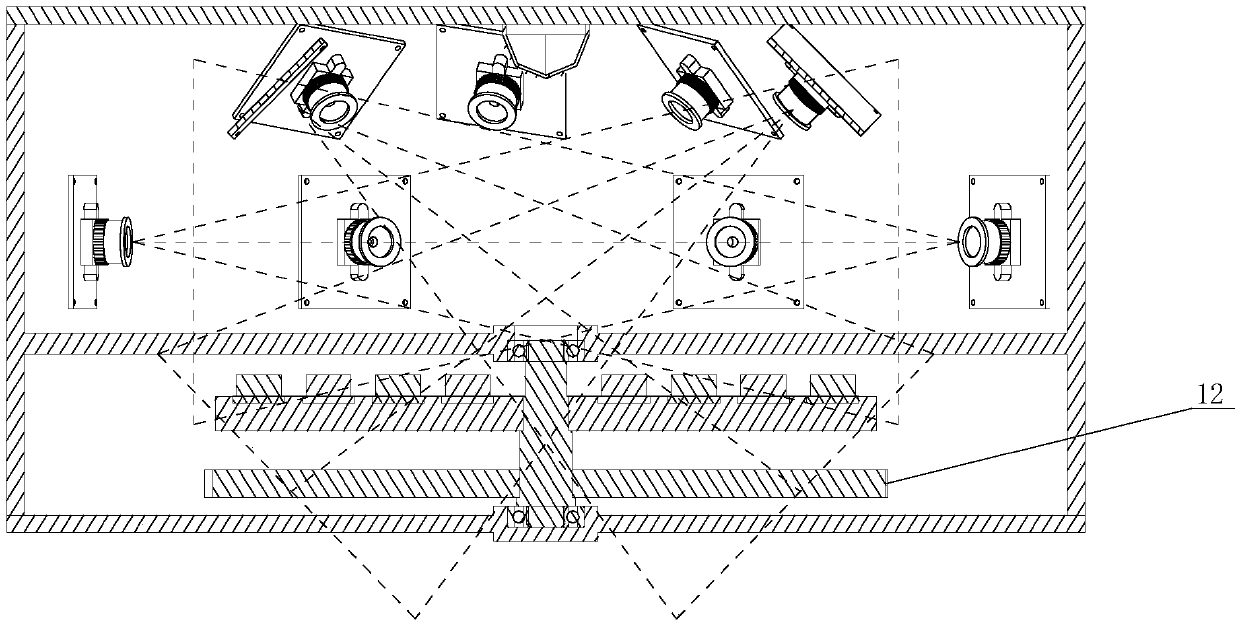

Embodiment 1

[0054] Table 1 Communication protocol between the main control module and the controller

[0055]

[0056]

[0057]

[0058] To sum up, this vacuum conductive ring wear debris imaging monitoring device, after the test starts, first extracts the image brightness at the position of the brightness standard block, and then corrects the image brightness. At this time, there is no wear debris inside the vacuum chamber 1, and the two The first image is used as a reference image. After the stepping motor 11 starts to rotate, the camera 13 is controlled for imaging. The image obtained by each imaging is corrected according to the brightness of the standard block, and the difference image is used to detect the position of the wear debris in the image. 13 After installation, calibrate the camera 13 to obtain the spatial pose relationship and the overlapping area of the field of view of the two cameras 13, eliminate repeated wear debris in the image based on this information, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap