A variable speed transmission device for a vehicle

A technology of variable speed transmission and vehicle, applied in transmission, transmission control, fluid transmission, etc., can solve problems such as low transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described by describing the embodiments below in conjunction with the accompanying drawings.

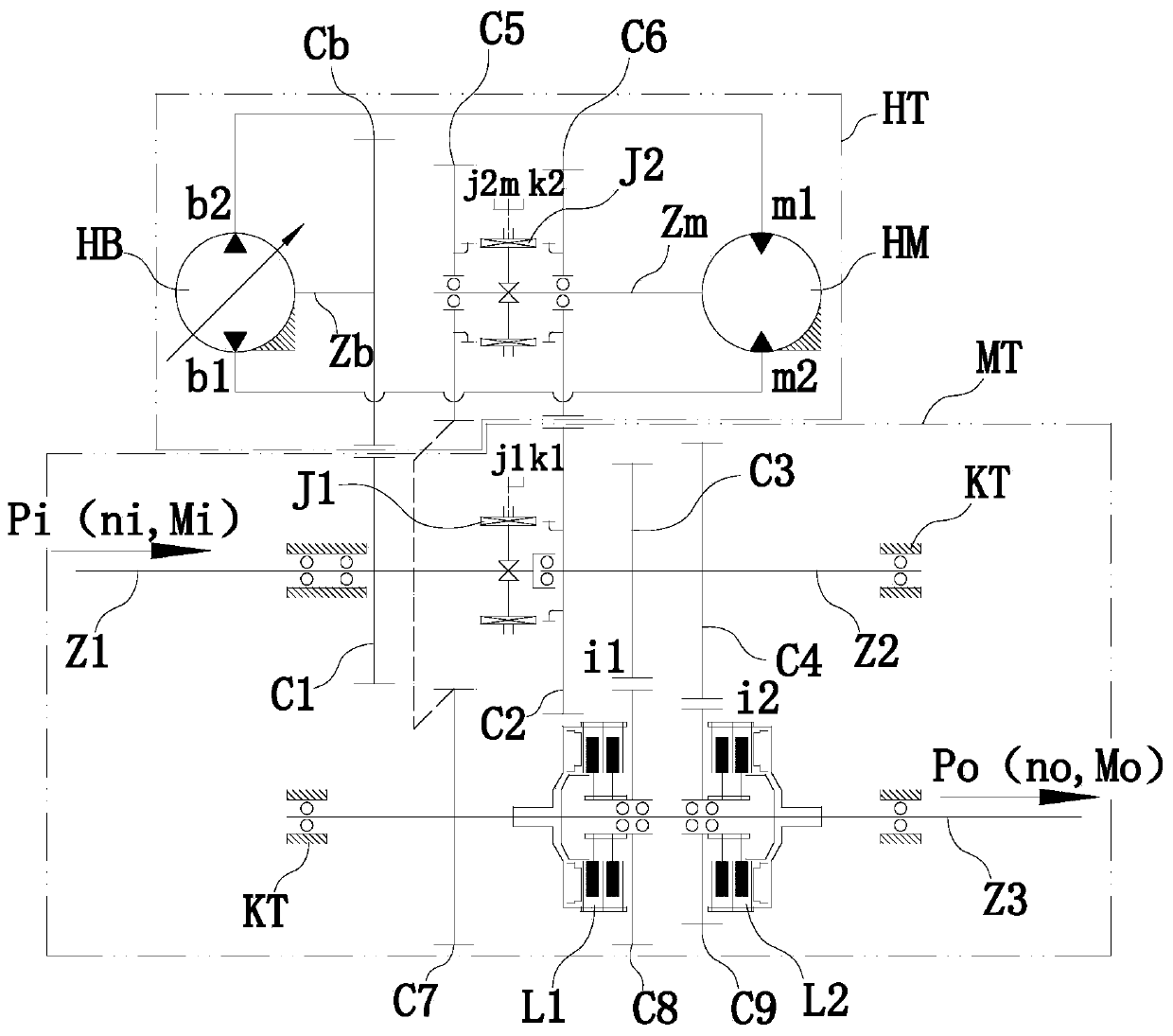

[0027] see figure 1 As shown, the present embodiment provides a transmission device for a vehicle, which is composed of a mechanical transmission module MT, a hydraulic transmission module HT and a device housing KT.

[0028] Among them, the mechanical transmission module MT includes the first shaft Z1, the second shaft Z2, the third shaft Z3, the transfer gear C1, the second shaft driven gear C2, the low gear driving gear C3, the high gear driving gear C4, the third shaft Driven gear C7, low gear driven gear C8, high gear driven gear C9 and first adapter J1, low gear clutch L1, high gear clutch L2.

[0029]The first shaft Z1 is the power input shaft of the speed change transmission device, on which the transfer gear C1 is fixed in turn, and the first adapter J1 is sleeved; the first adapter J1 rotates synchronously with the first shaft Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com