Evaporation and drying device for paclitaxel liposome

A technology of evaporative drying and liposomes, which is applied in the field of evaporative drying devices for paclitaxel liposomes, can solve problems such as easy leakage accidents, achieve the effects of reducing leakage accidents, ensuring compaction effect, and increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

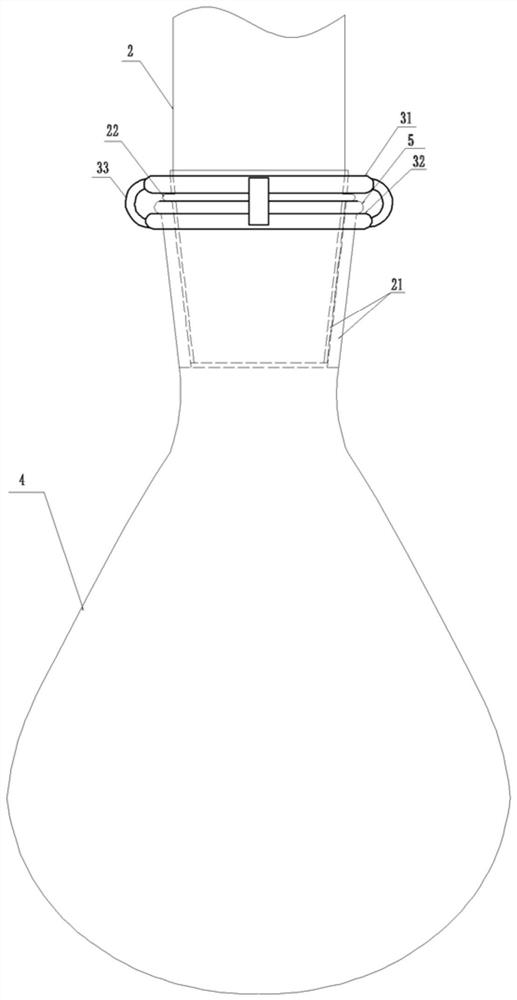

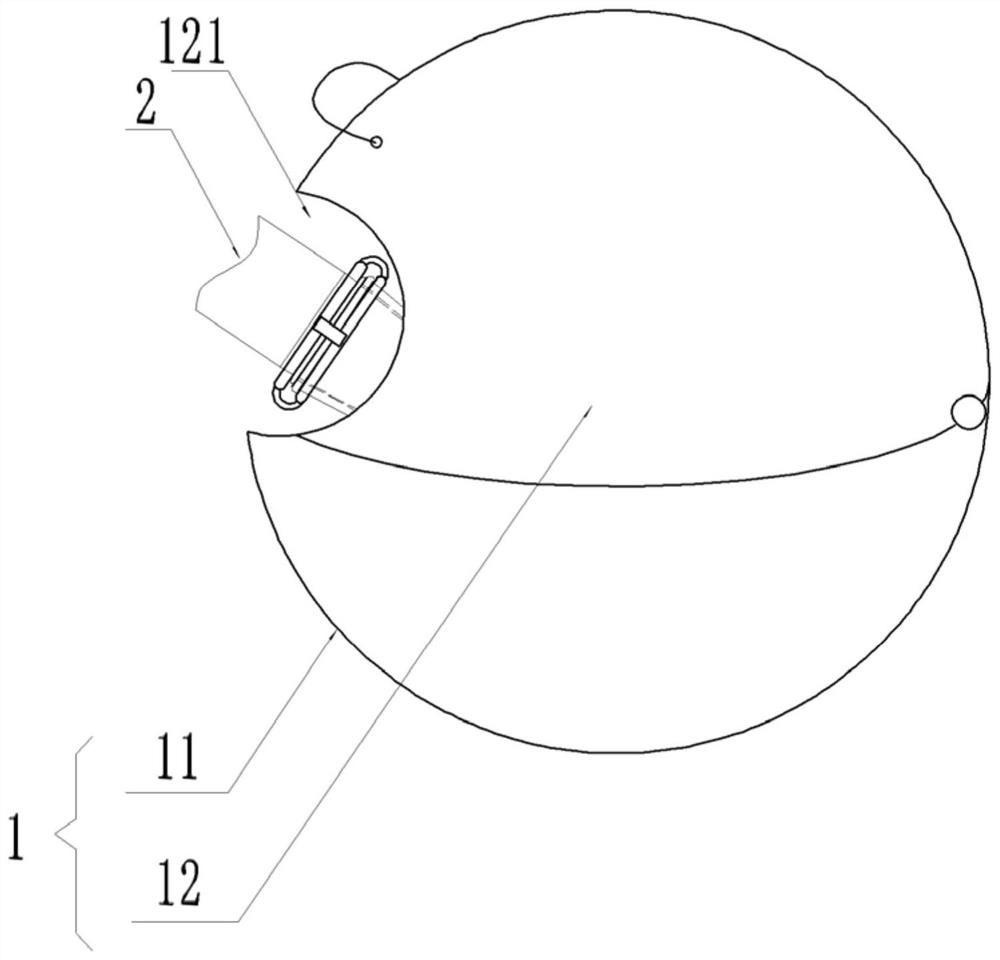

[0031] Basic as attached Figures 1 to 3 Shown:

[0032] The evaporative drying device of paclitaxel liposome comprises frame in the prior art, processing table, water bath 1, rotary bottle 4, bottle clamp 3, steam pipe 2 and two rubber sealing layers 21; water bath 1 and frame All are located on the processing table, and the steam pipe 2 is positioned on the frame. In order to facilitate the insertion of the steam pipe 2 into the rotary bottle 4, the diameter of the mouth of the steam pipe 2 is less than the diameter of the steam pipe 2 body. The outer wall of the nozzle of the steam pipe 2 is glued with a rubber sealing layer 21 . The bottle neck inner wall of the rotary bottle 4 is also bonded with a rubber sealing layer 21. When the steam pipe 2 is inserted into the rotary bottle 4, the two rubber sealing layers 21 are in contact with each other, thereby realizing the sealing of the two; and the rotary bottle 4 can be stretched into In the water bath 1, the water in the ...

Embodiment 2

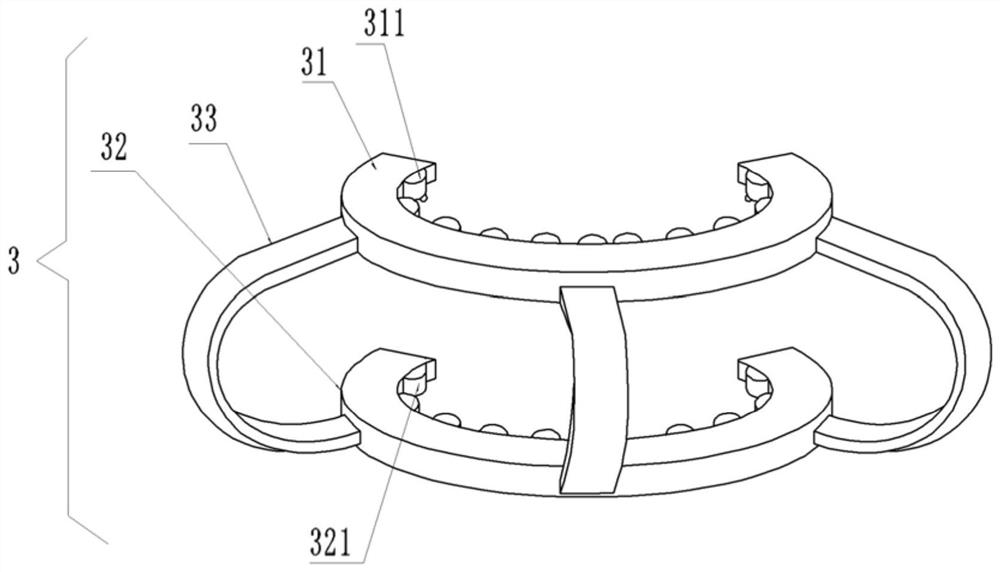

[0039] The difference between this embodiment and Embodiment 1 is that the connecting strip 33 is a deformable elastic material, such as Figure 4 As shown, the connecting strip 33 is provided with a cavity 331, and the cavity 331 is provided with a soft bag 332. The soft bag 332 in this embodiment can be a thicker PVC plastic bag, and its outer wall is wrapped with a cotton cloth layer; the soft bag 332 Both sides are bonded to the cavity wall of the cavity 331; a metal strip 333 is stuck on the soft bag 332, and the soft bag 332 is filled with supersaturated solution sodium acetate 3321 (note that it cannot be filled when filling); the entire connecting strip 33 is mainly It is formed by supporting the metal strip 333.

[0040] During use, the hot air in the water bath 1 gushes out from the gap 121, and the hot air contacts the connecting bar 33, and then heats the supersaturated solution sodium acetate 3321 in the connecting bar 33, and the supersaturated solution sodium ac...

Embodiment 3

[0042] In this embodiment, on the basis of Embodiment 2, a through hole is provided on the wall of the cavity 331, and the hot air in the water bath can enter the cavity 331 through the through hole, further speeding up the contact speed between the soft bag 332 and the hot air.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap