SMT mounting steel mesh for increasing tin soldering amount

A stencil and soldering technology, which is applied to screen printing machines, printed circuits assembled with electrical components, rotary printing machines, etc., can solve the problem that the amount of tin can not be satisfied, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Example one:

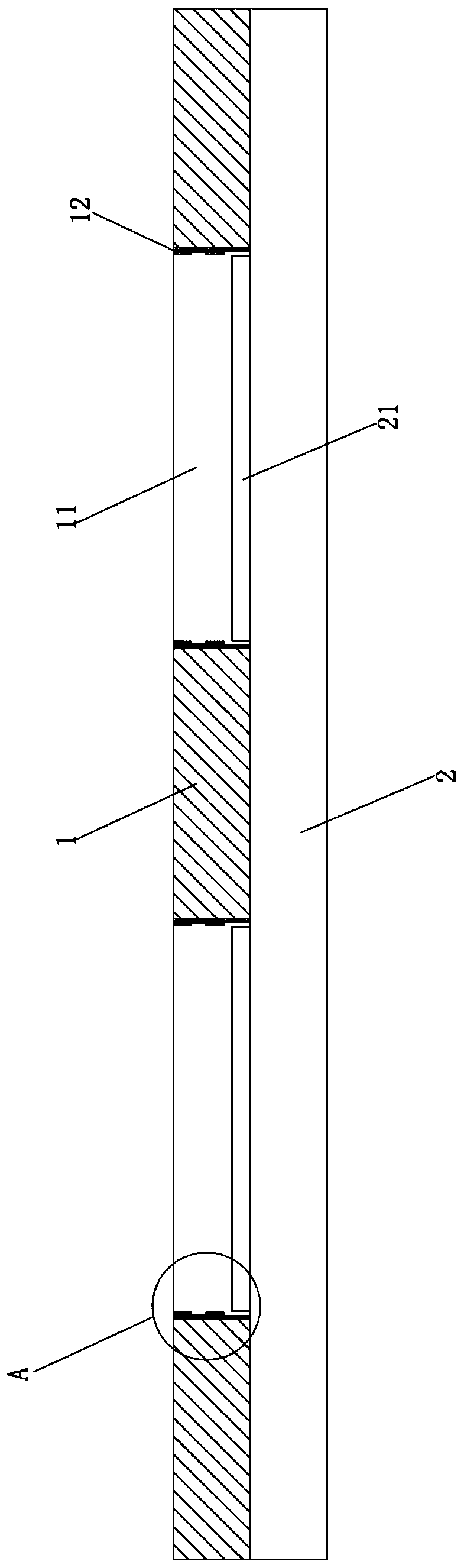

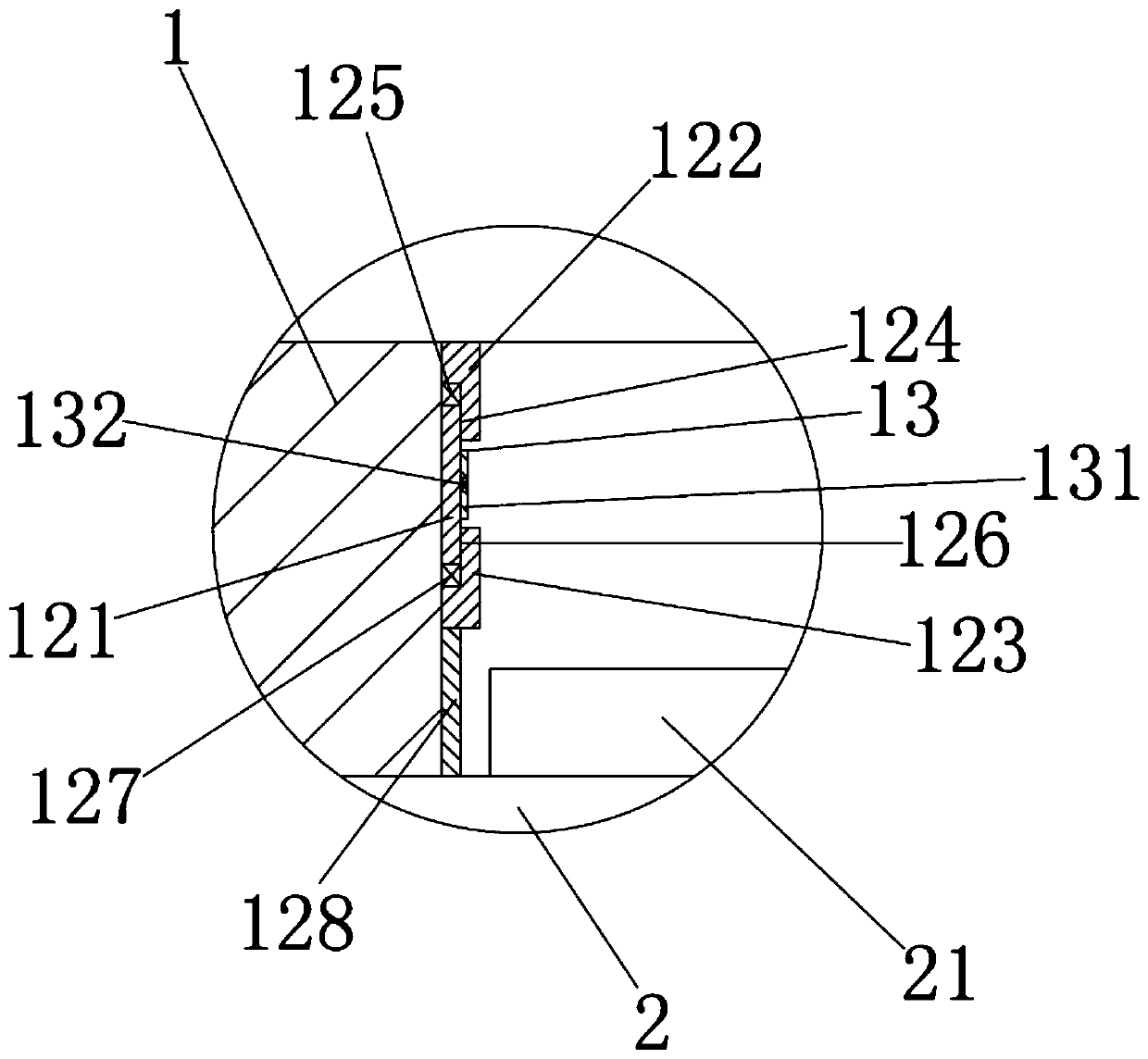

[0019] See Figure 1 to Figure 2 , The figure shows a stencil for SMT mounting with increased soldering volume provided by the first embodiment of the present invention, which includes a stencil substrate 1, on which a plurality of solder holes 11 are opened, and 11 sets of solder holes On the electronic component 21 of the circuit board 2, a plurality of solder diversion mechanisms 12 are provided on the wall of the solder hole 11, and the solder diversion mechanism 12 includes a mounting base 121 fixedly mounted on the hole wall of the solder hole 11. The opposite sides of the base block 121 are respectively elastically connected with a first diversion block 122 and a second diversion block 123, the end of the first diversion block 122 extends toward the top hole of the solder hole 11, and the second diversion block 123 The ends of the two extend in the direction of the circuit board 2.

[0020] The stencil for SMT mounting provided by this embodiment to i...

Example Embodiment

[0021] Embodiment two:

[0022] See Figure 1 to Figure 2 , The figure shows a steel mesh for SMT mounting with increased soldering volume provided by the second embodiment of the present invention. On the basis of the above-mentioned embodiment, this embodiment further makes the following as an improved technical solution: A first installation groove 124 is opened on the end surface of a flow guide block 122, the end of the installation base block 121 is inserted into the first installation groove 124, and the first spring 125 is installed in the first installation groove 124; at the same time, the second flow guide The end surface of the block 123 is provided with a second installation groove 126, the end of the installation base block 121 is inserted into the second installation groove 126, and a second spring 127 is installed in the second installation groove 126.

[0023] Through the arrangement of the above structure, the installation of the first air guide block and the sec...

Example Embodiment

[0024] Embodiment three:

[0025] See Figure 1 to Figure 2 , The figure shows a stencil for SMT mounting with increased solder volume provided in the third embodiment of the present invention. On the basis of the above-mentioned embodiment, this embodiment further makes the following as an improved technical solution: The ends of the two air guiding blocks 123 are connected with a third air guiding block 128 extending in the direction of the circuit board 2; the third air guiding block 128 is a rectangular air guiding block. Through the arrangement of the above-mentioned structure, the further diversion of the solder to the bottom of the electronic component can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com