Double-face gate valve

A double-sided gate valve and valve stem technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of affecting valve sealing, increasing wear of sealing materials, easy oxidation and rusting, etc., to improve sealing and solve the problem of thread The effect of difficult rotation and large lateral thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is used to disclose the specific content of the present invention so that those skilled in the art can realize the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

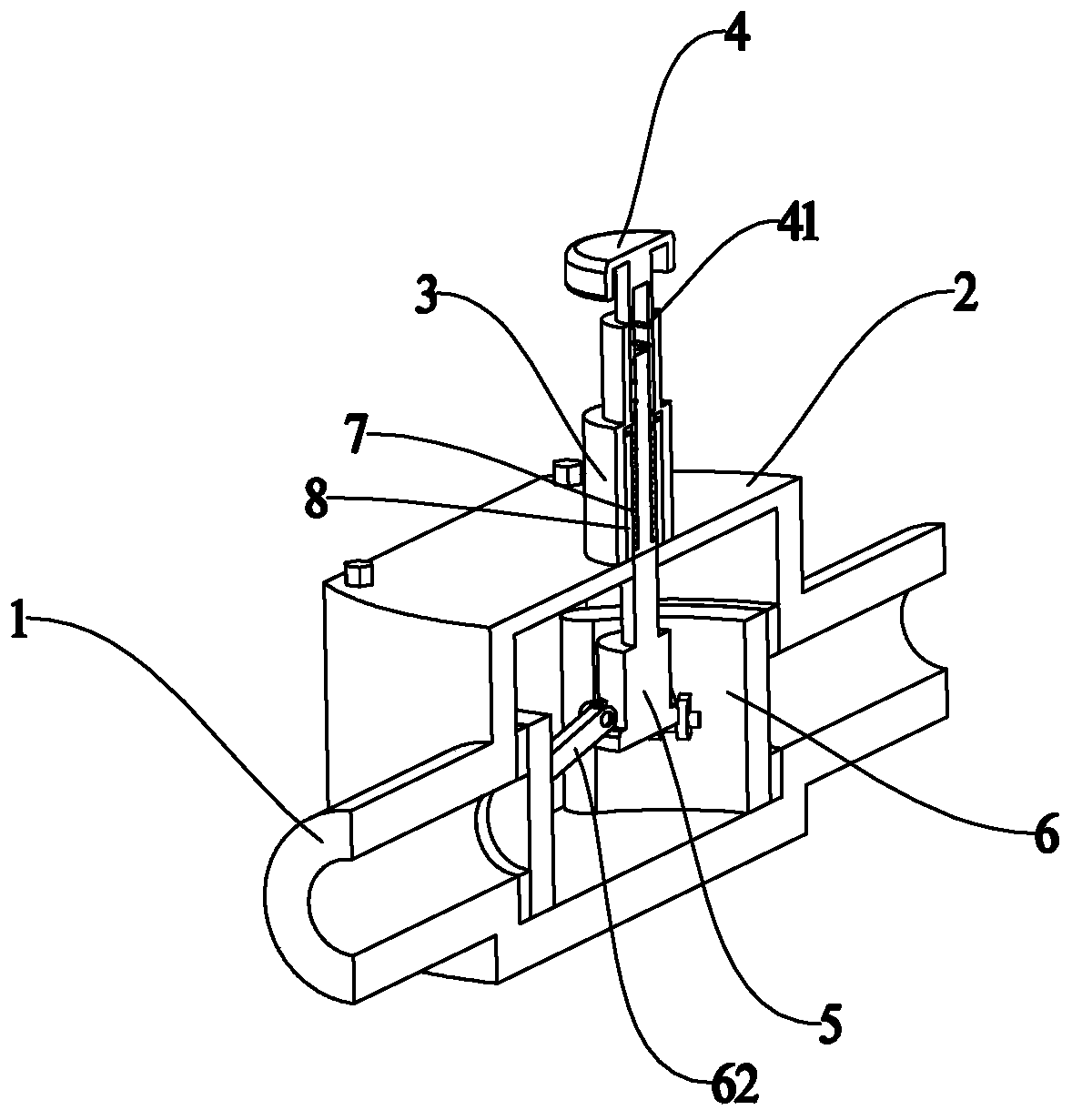

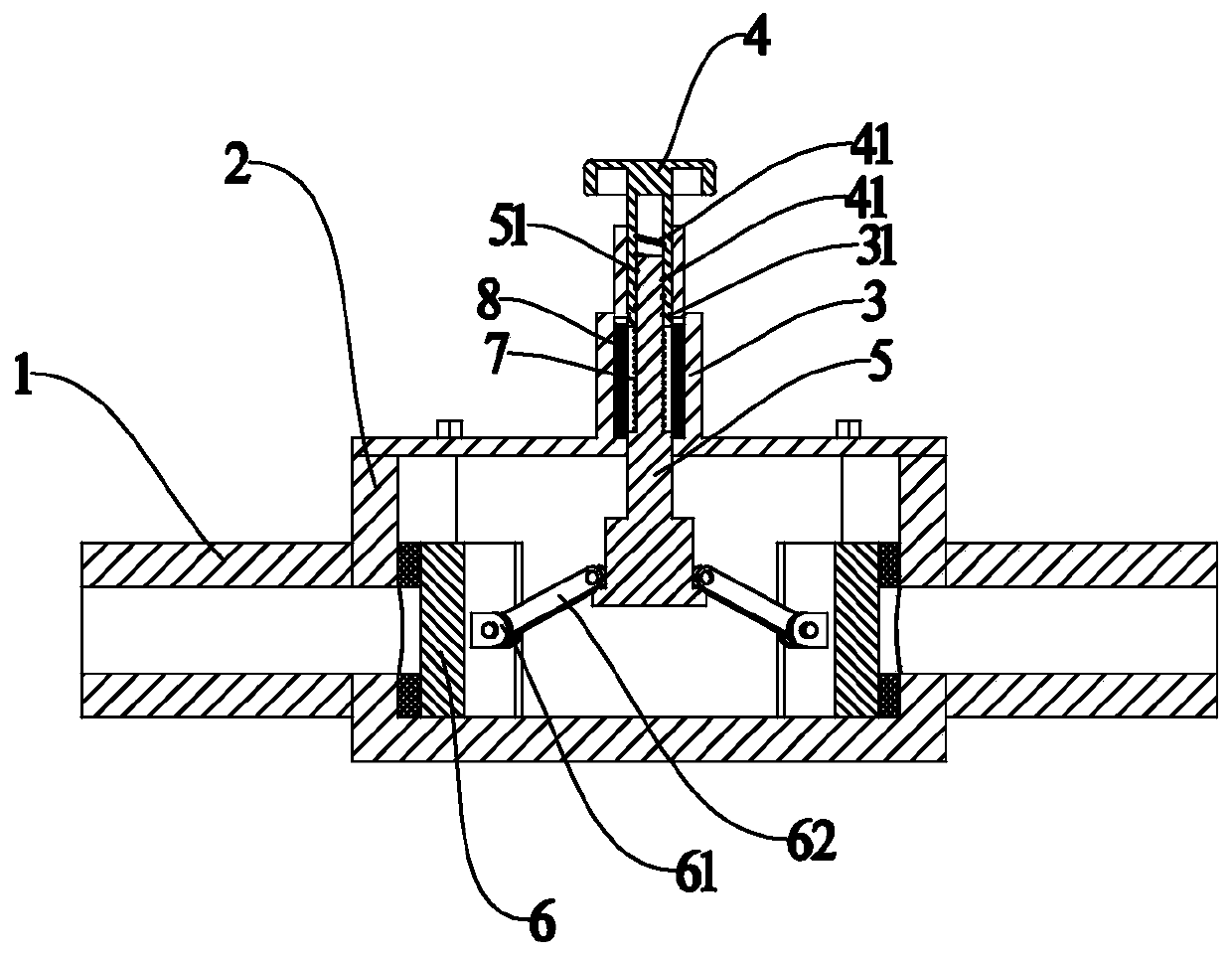

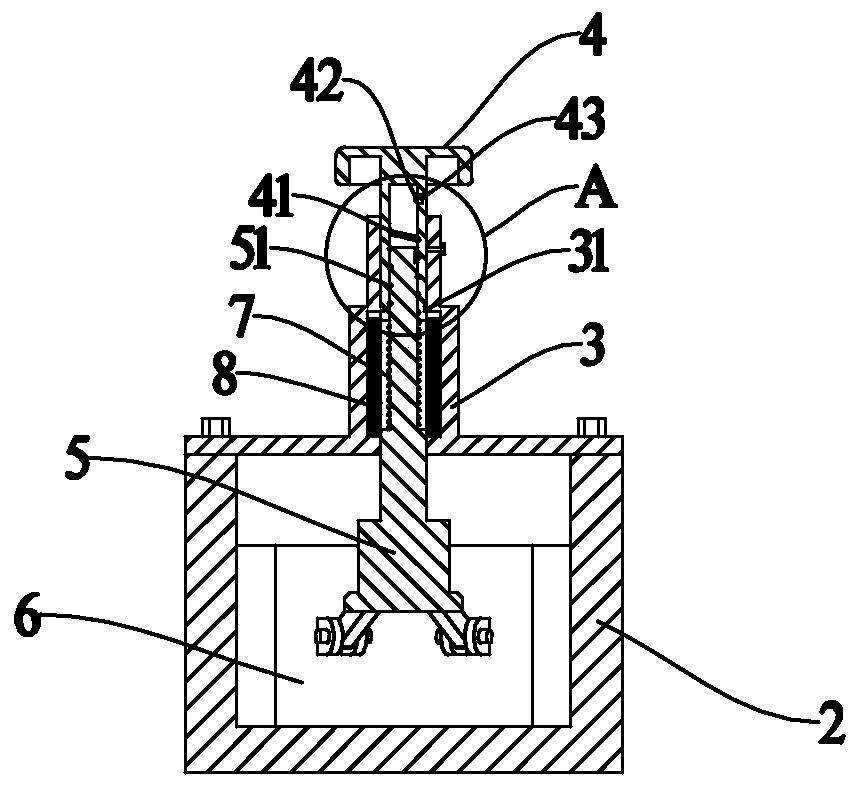

[0023] The embodiment of the present invention is a double-sided gate valve, which includes a valve body chamber 2, a valve stem 5 located in the center of the valve body chamber, channels 1 near the bottom of both sides of the valve body chamber, and the valve body chamber 2 is provided with channels 1 The two side plates are arc-shaped plates, and the valve body chamber 2 is provided with two rubber sealing plates 6 matched with the arc-shaped plates (the inner core is made of hard material and the outer ring is covered with rubber or the contact surface of the valve plate is covered with Rubber), each of the rubber sealing plates 6 is provided with two hinge pairs 61, each of the hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com