Single-row Disjoint Stochastic Machining Path Planning Method for Arbitrary Boundary Optical Components

A technology for optical components and processing paths, which is applied in the field of random path planning for small tool processing, and can solve problems such as path crossing, intermediate frequency errors, and difficulty in adapting to arbitrary boundary optical elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereto.

[0041] A method for generating a computer-controlled small tool processing path for an arbitrary boundary optical element, comprising the following steps:

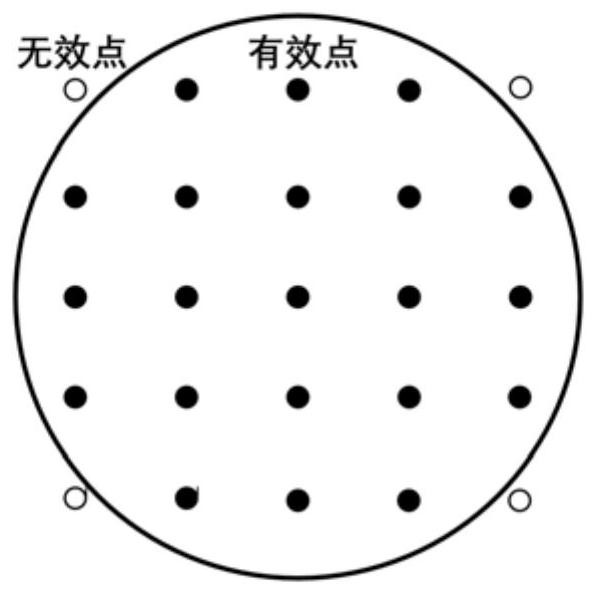

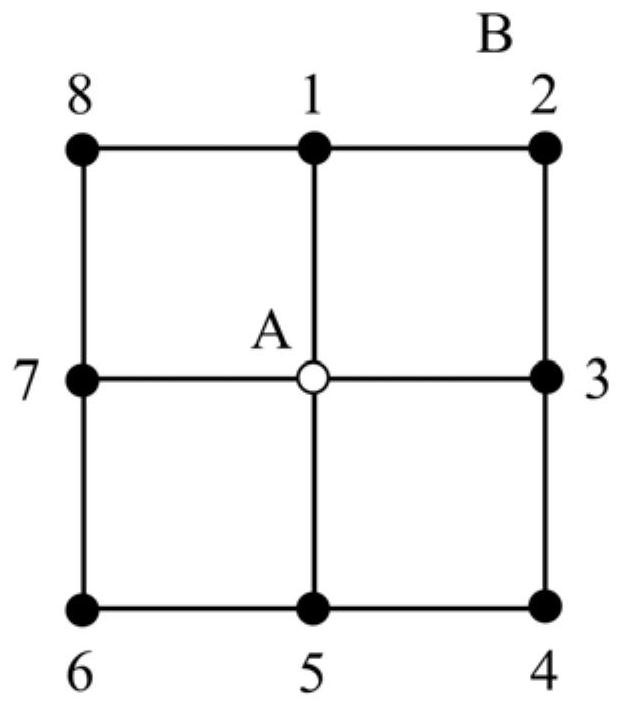

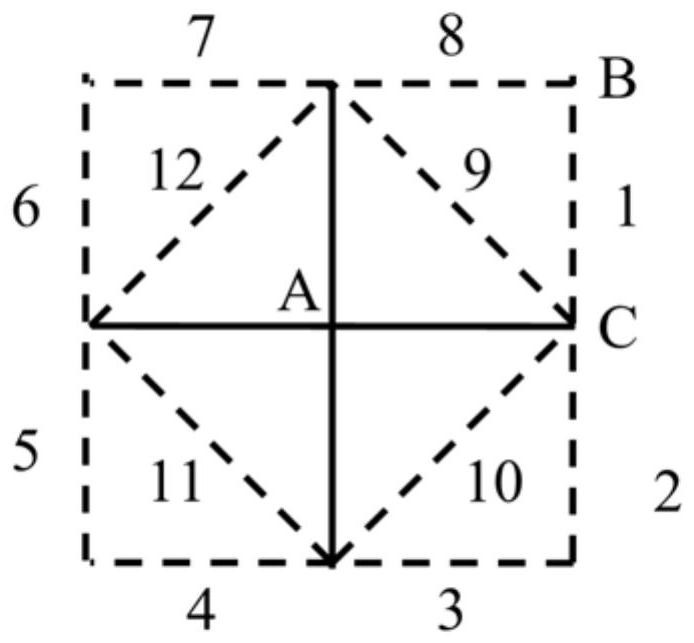

[0042] Step 1: Create three empty sets: a set of path points, a set of non-path points and a set of adjacent points. The elements in the three sets are the coordinate pairs corresponding to the points: (abscissa, ordinate). The set of waypoints is ordered, the set of non-waypoints and the set of adjacent points are unordered. figure 1Shown is a schematic diagram of the mesh division. The caliber of the component to be processed is divided into grids, and the grid spacing is equal to the grid spacing when calculating the dwell time. Select a full-caliber rectangular area that can cover the continuation distance as the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap