Method for producing porcelain polished tiles imitating natural stone textures

A technology of imitating natural stone and production method, applied in the production field of imitating natural stone textured porcelain polished tiles, can solve the problems of artificial processing marks, unnaturalness, etc., and achieves rich layers, decent pattern changes, and rich and changeable colors and patterns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

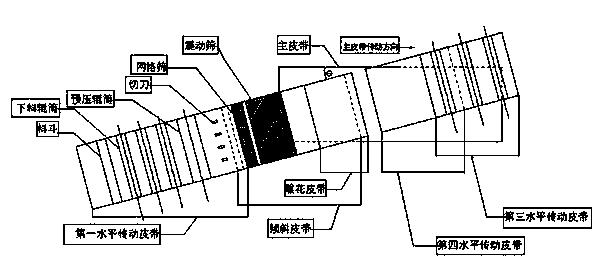

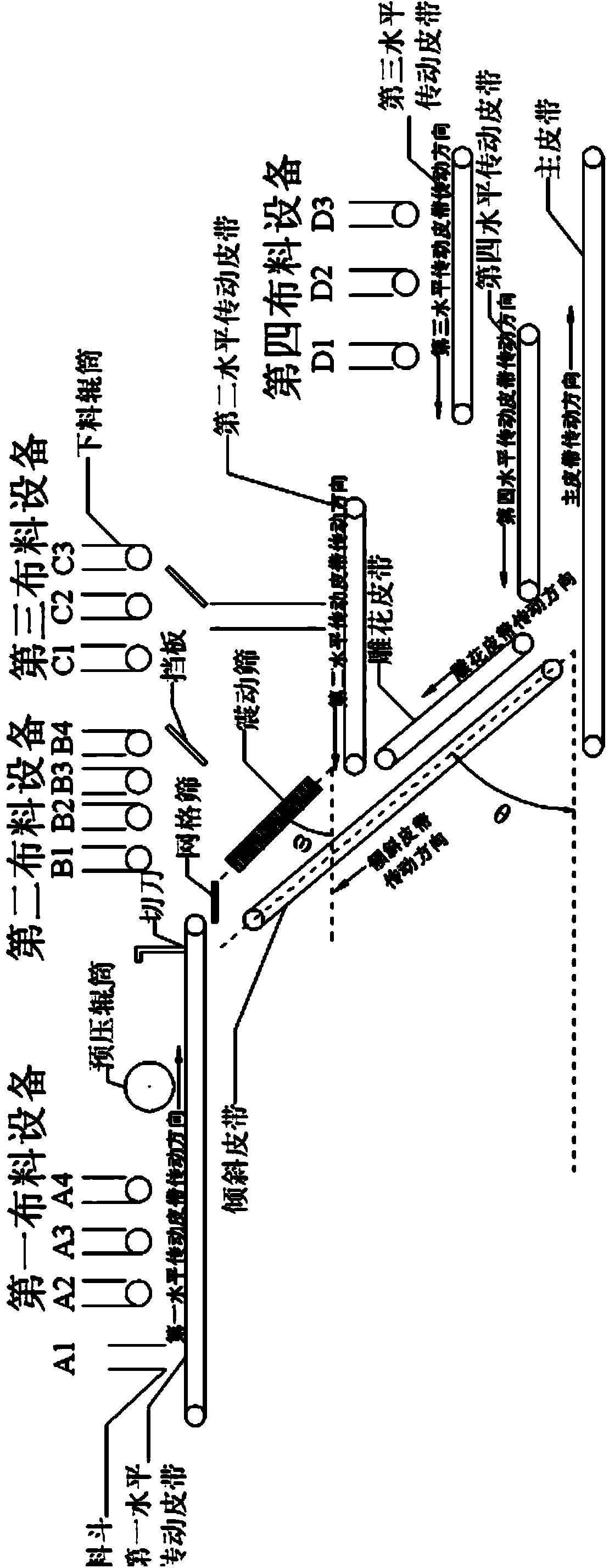

[0019] Such as figure 1 Shown, the concrete operation steps of the production method of imitation natural stone texture porcelain polished brick of the present invention are as follows:

[0020] The included angle φ formed by the first, second, third and fourth distributing equipment and the driving direction of the main belt is 15°.

[0021] In the first material distributing equipment, the high-temperature light yellow micro-powder fabric in the A1 hopper is lowered to the first horizontal transmission belt to form a certain thickness of powder layer. When passing through the A2 feeding roller, the high-temperature brown micro-powder fabric in A2 is controlled by the roller to the high temperature. Light yellow micro-powder fabric layer, followed by A3 and A4 are similar to A2, the high-temperature white micro-powder fabric of A3 is controlled by the feeding roller, and spread on the high-temperature brown micro-powder fabric, and the transparent yellow micro-powder fabric i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com