Flour tidying device for noodles, bean vermicelli and rice noodles

A technology for vermicelli and rice noodles, which is applied in the field of noodle, vermicelli and rice vermicelli noodle-arranging devices, can solve the problems of ordinary rotating noodle-arranging effect, easy hook and chain detachment, and hanging out of the box, so as to avoid major failures and move stably , good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

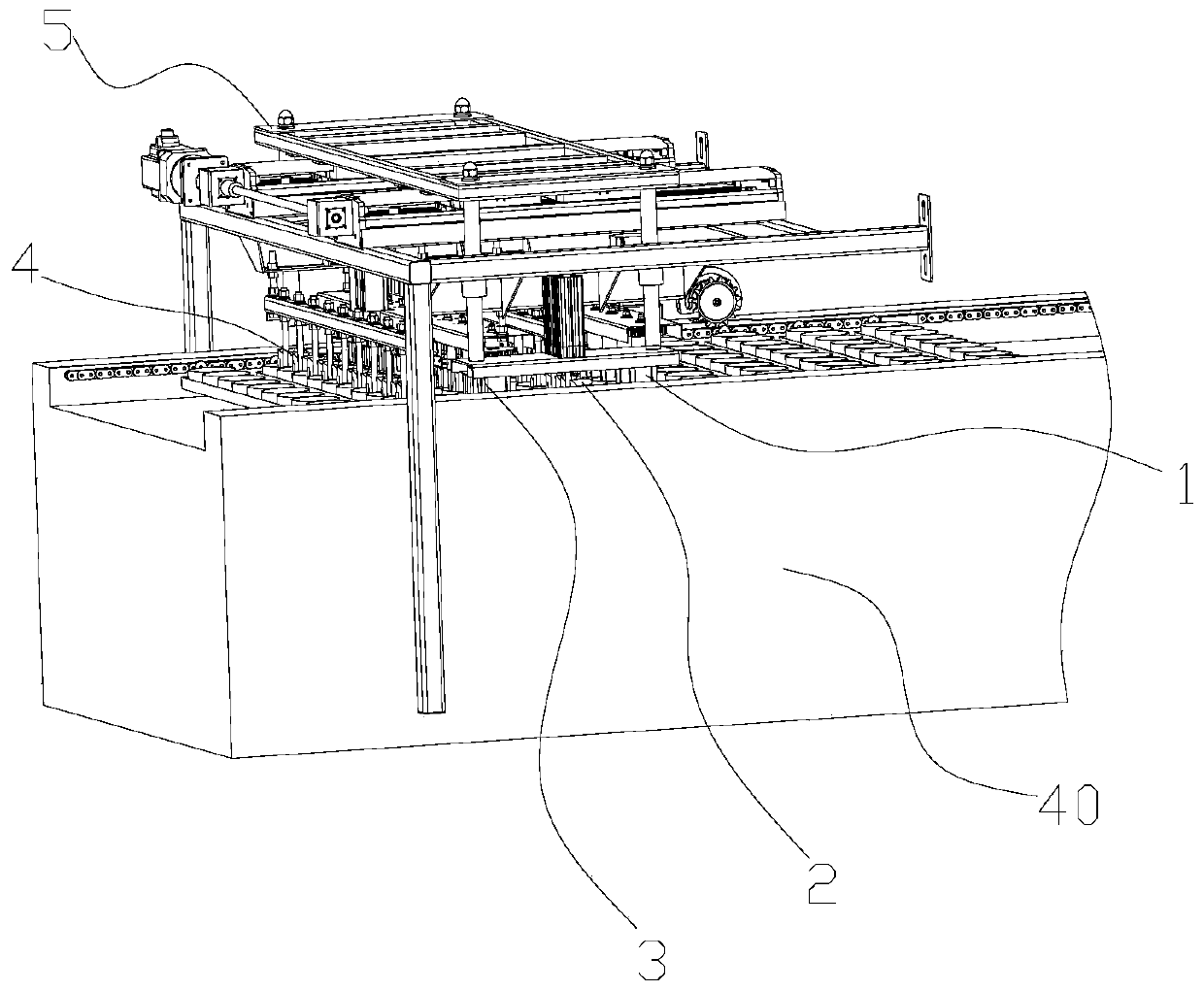

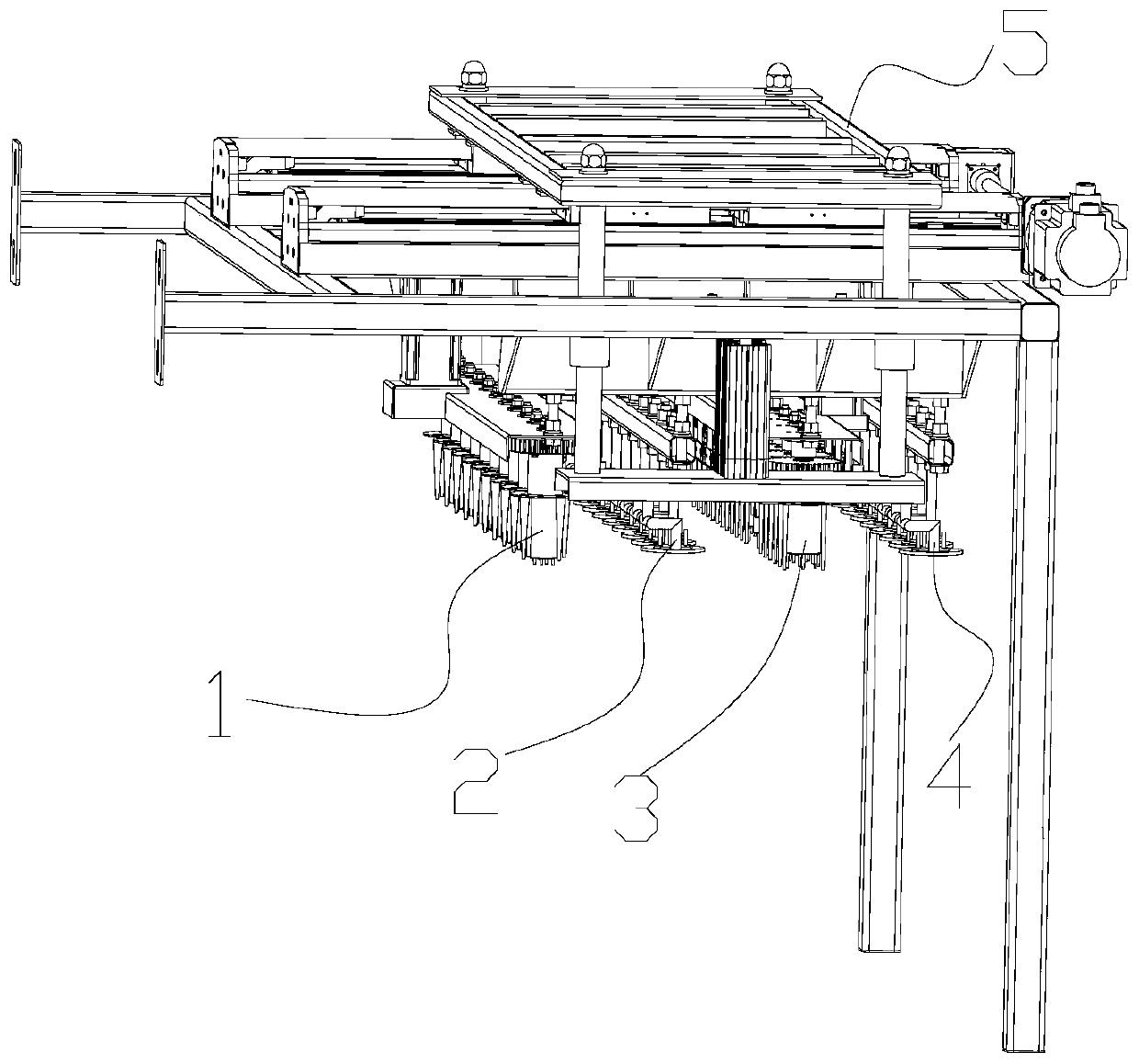

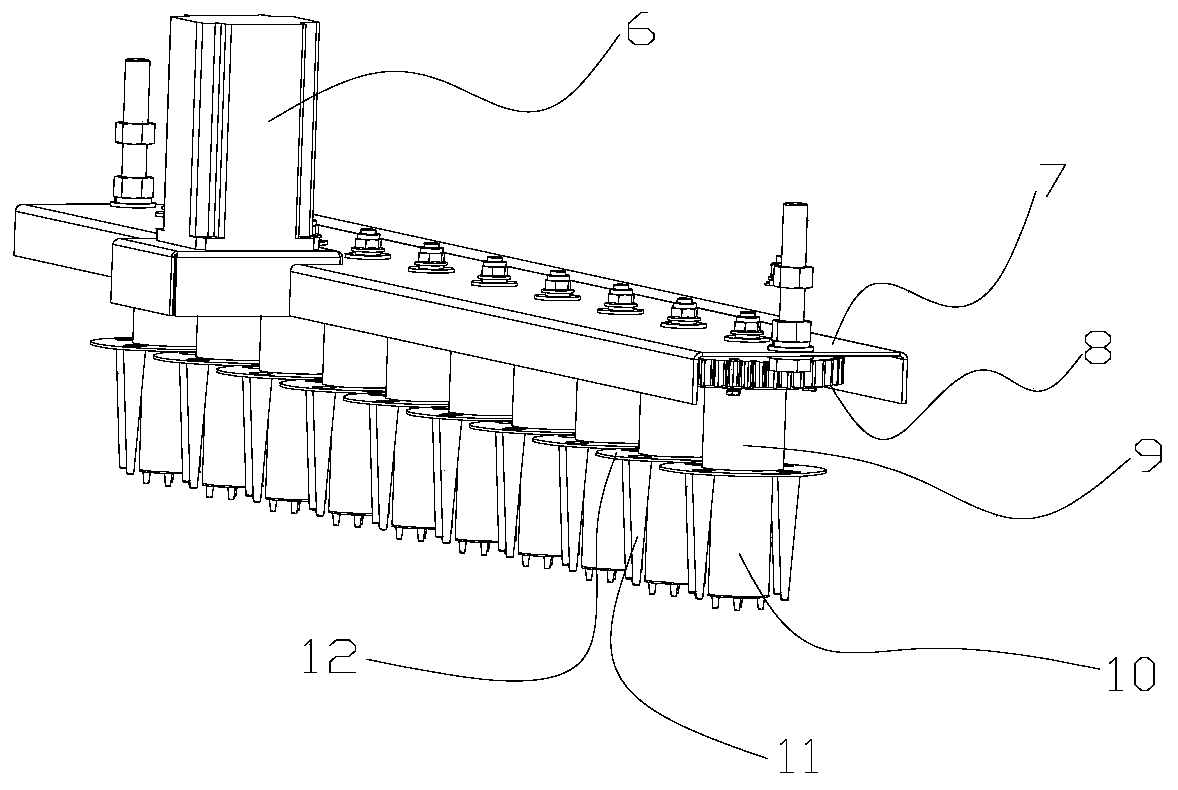

[0029] A noodle-making device for noodles, vermicelli and rice noodles, which includes a driving mechanism, a first rotating noodle-making mechanism, a second rotating noodle-making mechanism, and a molding mechanism; the molding mechanism includes a first molding mechanism and a second molding mechanism . The first rotating noodle-making mechanism, the first pressing mechanism, the second rotating noodle-making mechanism, and the second pressing mechanism are installed on the drive mechanism in sequence, and the driving mechanism drives the first rotating noodle-making mechanism, the second rotating noodle-making mechanism, the second rotating noodle-making mechanism, The first pressing mechanism and the second pressing mechanism move to realize surface finishing.

[0030]In this embodiment, the first rotating noodle cooking mechanism includes a fixed assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com