Fast lifting platform mechanism and using method

A technology for lifting platforms and lifting platforms, which is applied in the direction of lifting frames and lifting devices, and can solve problems such as instability, unfavorable production, and slow lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

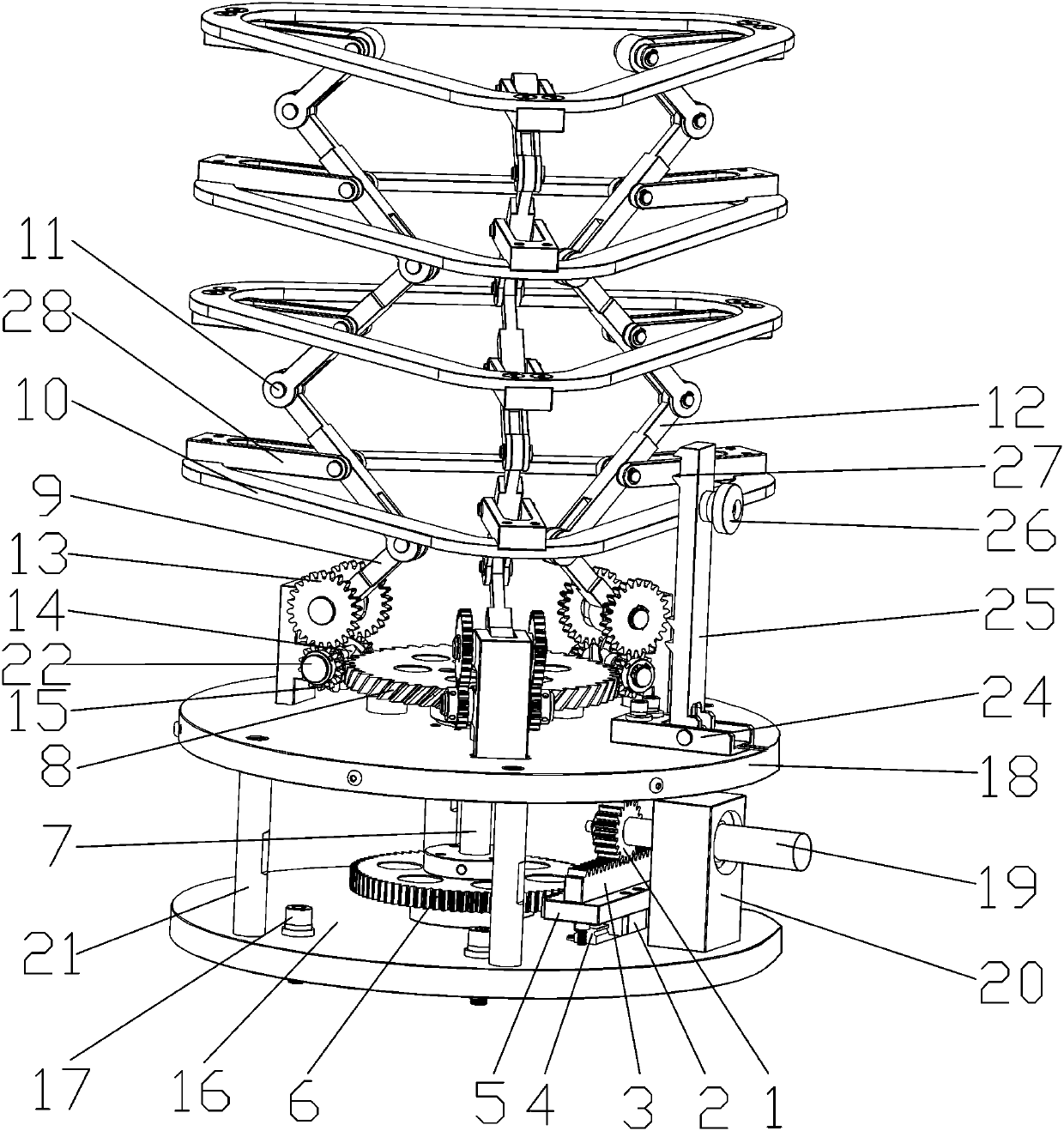

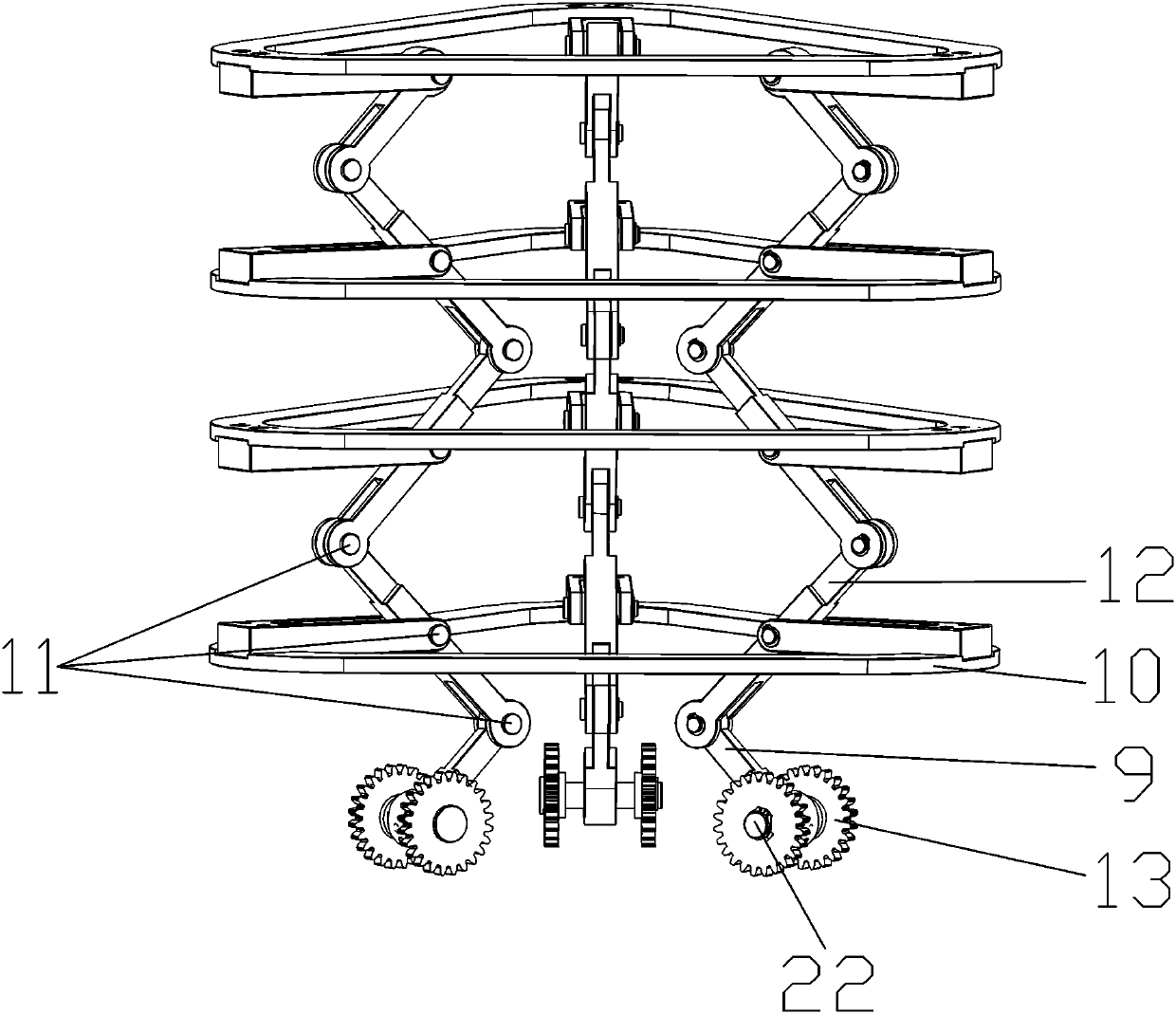

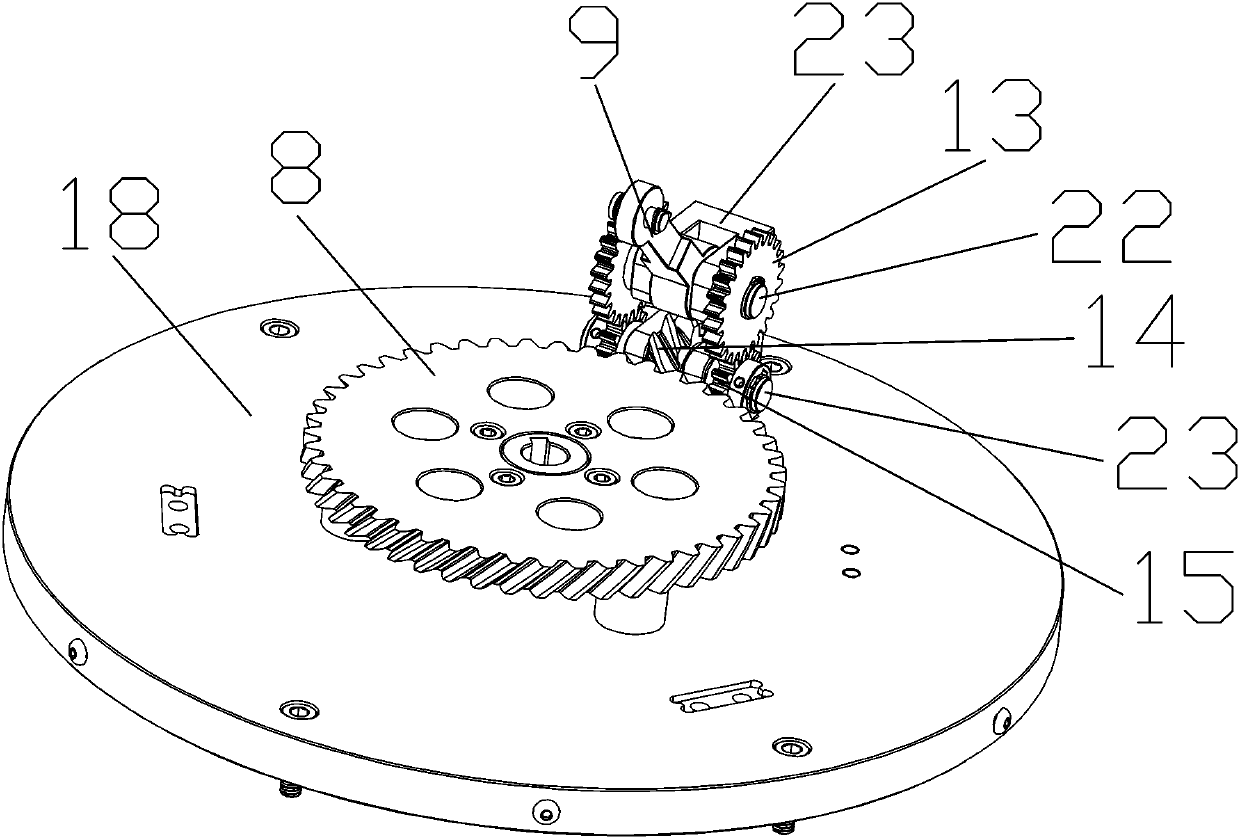

[0032] Such as Figure 1-3 Shown, a kind of fast lifting platform mechanism, it comprises platform base 16, and the top of described platform base 16 is supported with lifting base 18 by a plurality of evenly distributed supporting columns 21, and first gear is installed in the center of platform base 16 6. The first gear 6 is meshed with the power mechanism for driving it to rotate; the center of the first gear 6 is equipped with a vertical shaft 7, and the other end of the vertical shaft 7 passes through the lifting base 18, and is connected with the first The helical gear 8 is connected and transmits torque; the first helical gear 8 is supported on the top of the lifting base 18; The rotation output end of the transmission mechanism is connected with a short rod 9, and the other end of the short rod 9 is connected with the link type lifting platform, and drives it to lift. The jacking platform mechanism with the above structure can be used for jacking operations. During th...

Embodiment 2

[0041] A method for using a fast jacking platform mechanism, which includes the following steps:

[0042] Step1: Drive the first main shaft 19 through the motor, drive the second gear 1 through the first main shaft 19, then drive the first rack 3 through the second gear 1, drive the second rack 5 through the first rack 3, and then drive the second rack 5 through the first rack 3. The second rack 5 drives the first gear 6;

[0043] Step2: The first gear 6 will drive the vertical shaft 7, drive the first helical gear 8 through the vertical shaft 7, and then the first helical gear 8 will mesh with the second helical gear 14 for transmission;

[0044] Step3: The second helical gear 14 will drive the third main shaft 22, the third gear 15 will be synchronously driven by the third main shaft 22, and the fourth gear 13 will be synchronously driven by the third gear 15;

[0045] Step4: The fourth gear 13 will drive the third main shaft 22, and then the third main shaft 22 will drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com