A knob switch structure and automobile

A technology of knob switch and knob, which is applied in the direction of electric switches, electrical components, circuits, etc. It can solve the problems of inability to fold the exterior rearview mirror, shaking of the knob, and unsteady feeling, and achieve smooth mirror adjustment and folding, and stable and continuous rotation , smooth feel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

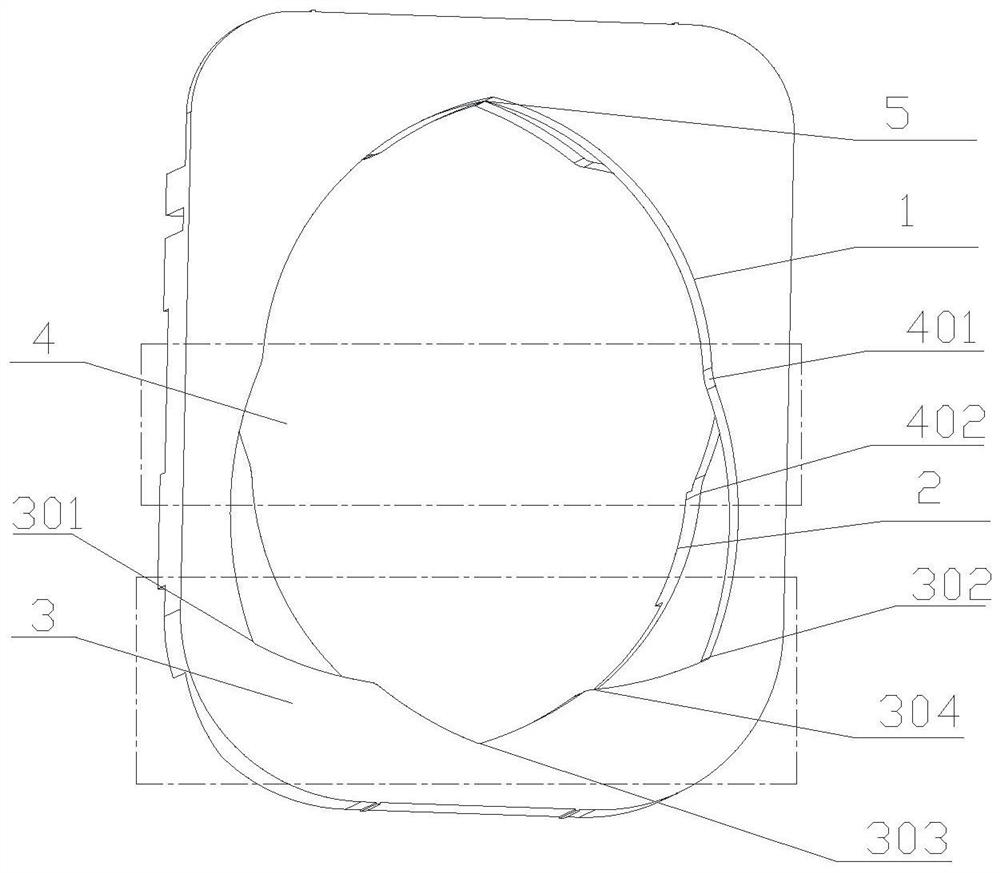

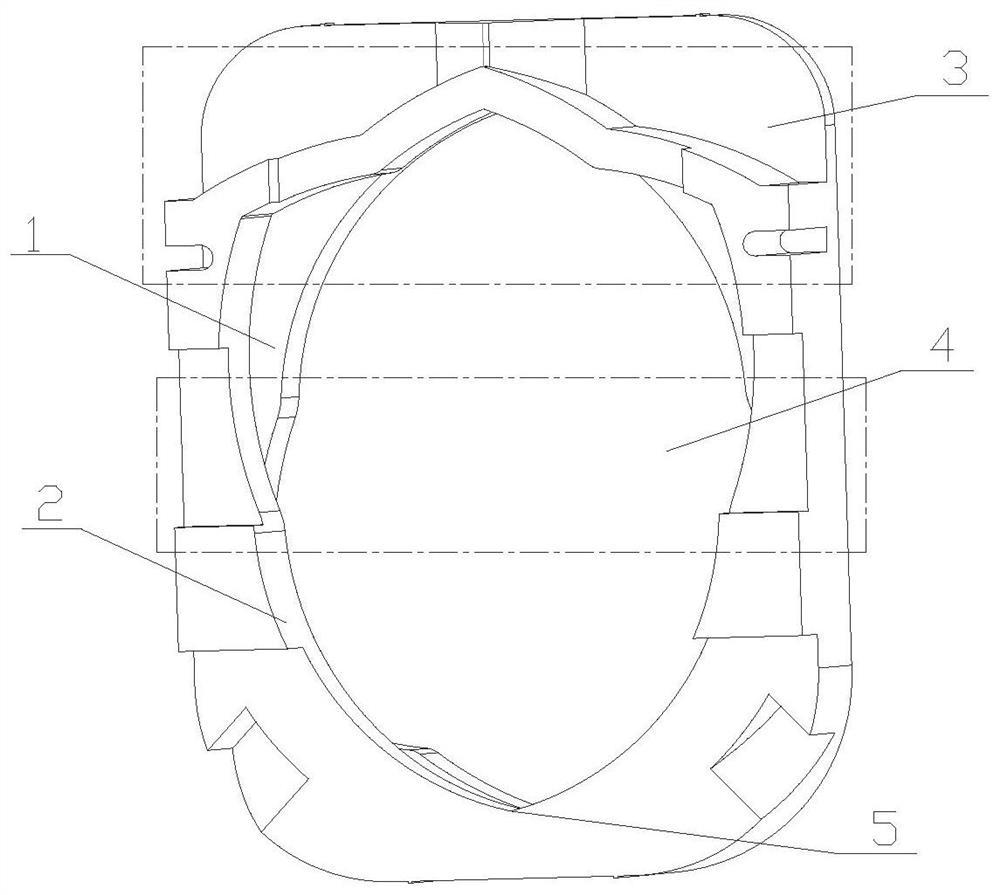

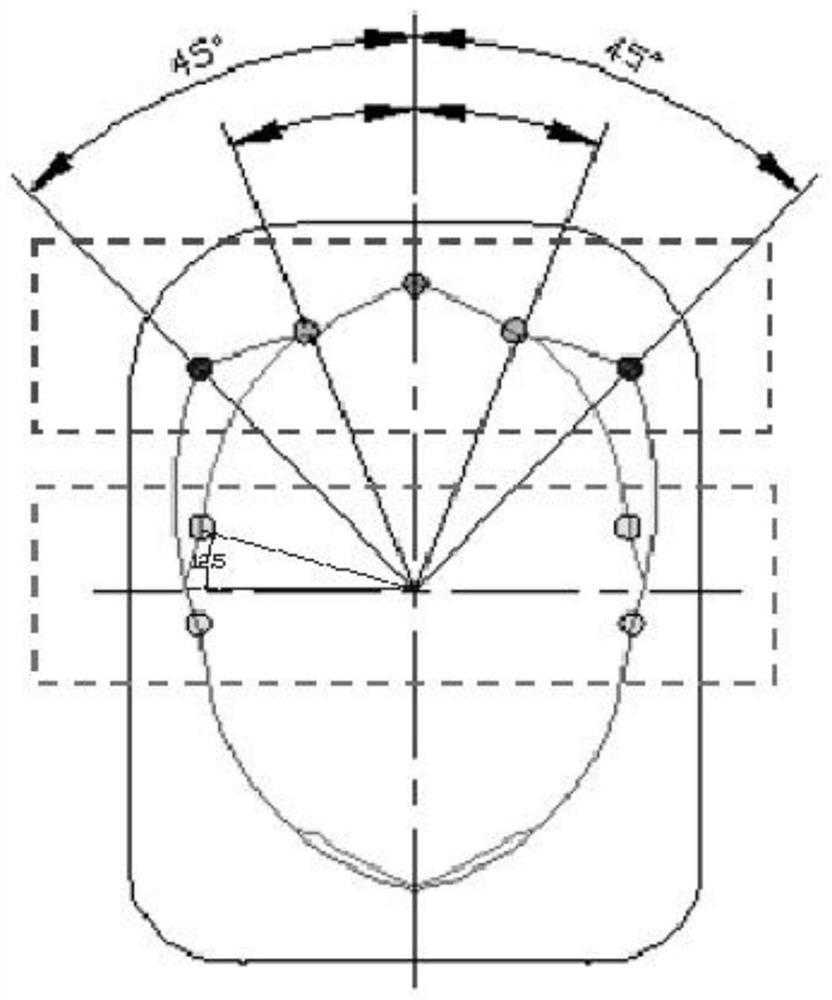

[0040] Such as Figure 1 to Figure 5As shown, a rotary switch structure includes a housing 7, a swing rod 10, a rotor 11 and a gear plate 13, the gear plate 13 is fixedly arranged on the housing 7, and the rotor 11 is sleeved on the swing rod 10, rotates synchronously with the swing rod 10, the shift plate 13 includes a first layer and a second layer, the first layer is formed with a through first opening 1, and the second layer is formed with There is a through second opening 2, the first opening 1 includes a smooth shift part 3 and a sudden shift area 4, the second opening 2 has the same structure as the first opening 1, the first The second opening 2 rotates 180° along the axial centerline of the first opening 1 to coincide with the first opening 1;

[0041] It also includes a first prop 15 and a second prop 16, one end of the first prop 15 is fixedly connected to the rotor 11, the other end slides along the inner wall of the first opening 1, and the second prop 16, one e...

Embodiment 2

[0052] Embodiment 2: be the preferred embodiment of embodiment 1,

[0053] Such as Figure 1 to Figure 5 Shown: a rotary switch structure, including a housing 7, a swing rod 10, a rotor 11 and a gear plate 13, the gear plate 13 is fixedly arranged on the housing 7, and the rotor 11 is sleeved on the swing rod 10, rotates synchronously with the swing rod 10, the shift plate 13 includes a first layer and a second layer, the first layer is formed with a through first opening 1, and the second layer is formed with There is a through second opening 2, the first opening 1 includes a smooth shift part 3 and a sudden shift area 4, the second opening 2 has the same structure as the first opening 1, the first The second opening 2 rotates 180° along the axial centerline of the first opening 1 to coincide with the first opening 1;

[0054] It also includes a first prop 15 and a second prop 16, one end of the first prop 15 is fixedly connected to the rotor 11, the other end slides along ...

Embodiment 3

[0076] Embodiment 3: be the preferred embodiment of embodiment 2

[0077] The difference with embodiment 2 is characterized in that:

[0078] The angle between the centerline in the horizontal direction of the gear mutation area 4 of the first opening 1 and the first mutation point 401 is 10° or 15°, and the gear position of the second opening 2 The included angle between the horizontal center line of the mutation region 4 and the second mutation point 402 is 10° or 15°.

[0079] Described contact bridge 18 is provided with two, and two described contact bridges 18 are all provided with contact bridge pressure spring 19, and described movable contact 14 is provided with two, and two described movable contacts 14 are all provided with The movable contact compression spring 20 and the rotor 11 can be adjusted in different directions through the conduction of different contact bridges 18 .

[0080] Furthermore, the support pin 23 is fixedly connected to the swing rod 10 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com