Length-adjustable prefabricated component lifting supporting device

A technology of prefabricated components and support devices, applied in building construction, building material processing, construction, etc., can solve the problems of collision damage to other objects, lack of protective devices, and reduced use efficiency of support devices, and achieve the effect of reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

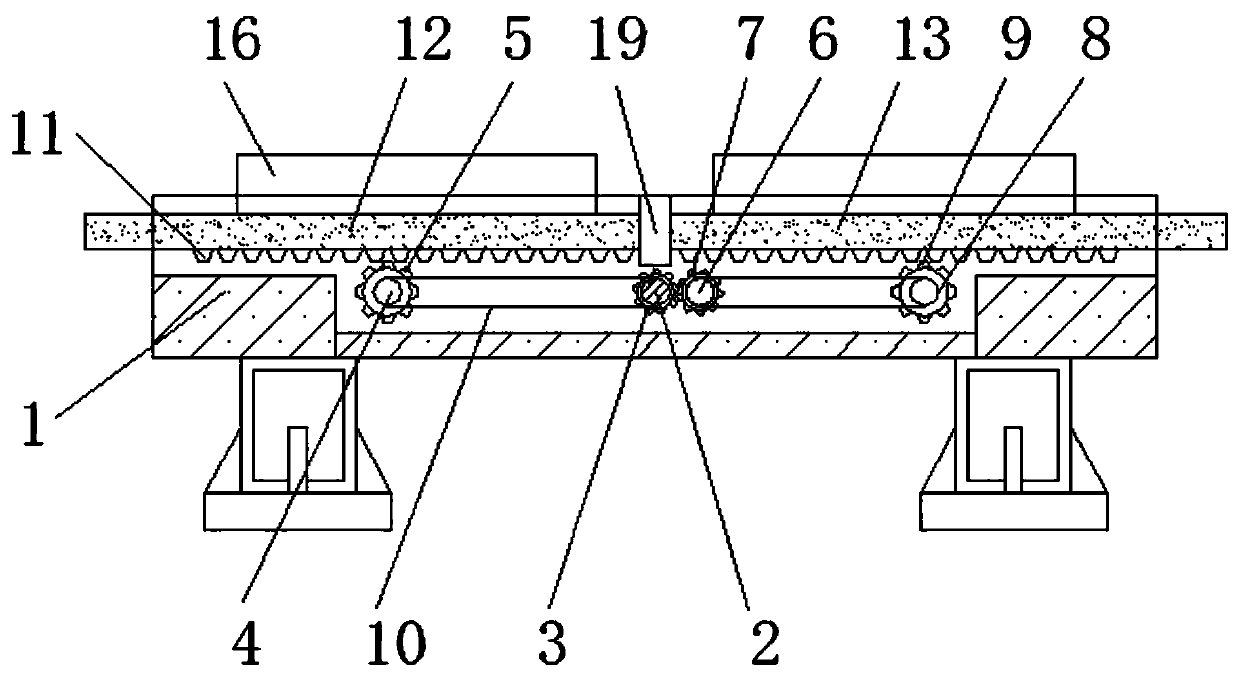

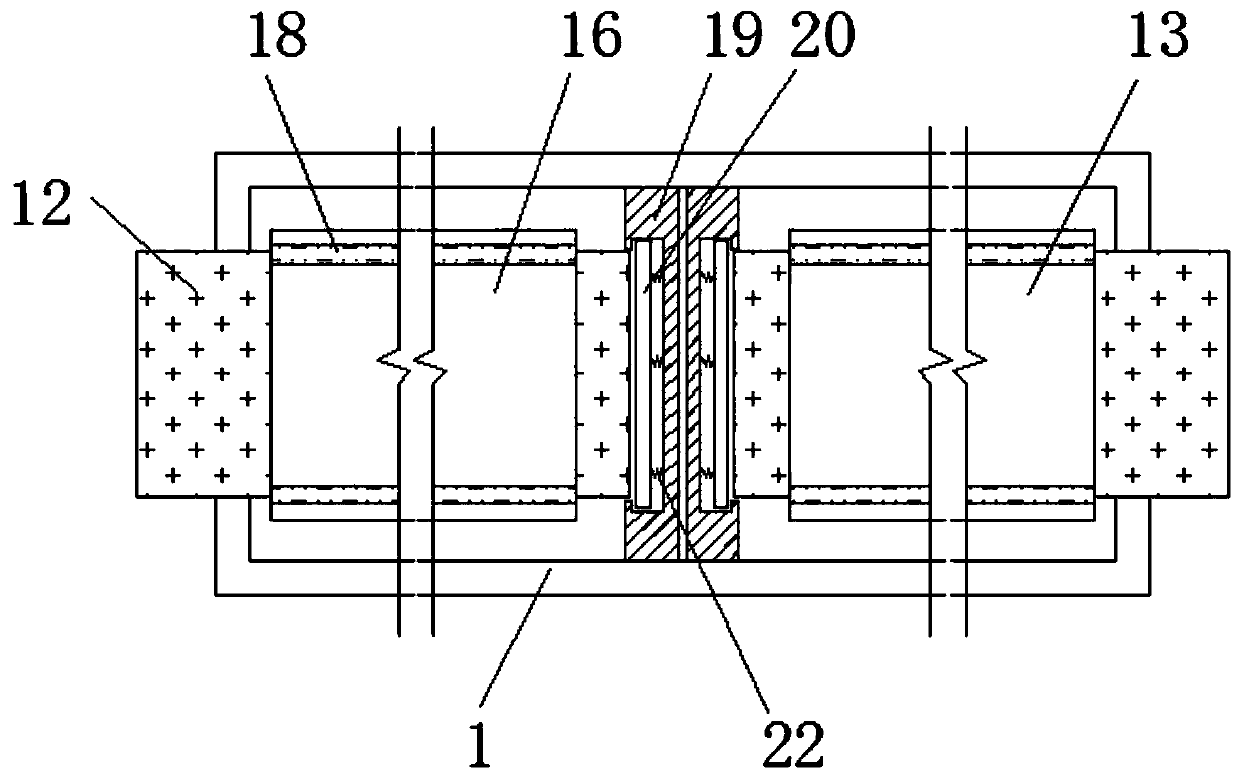

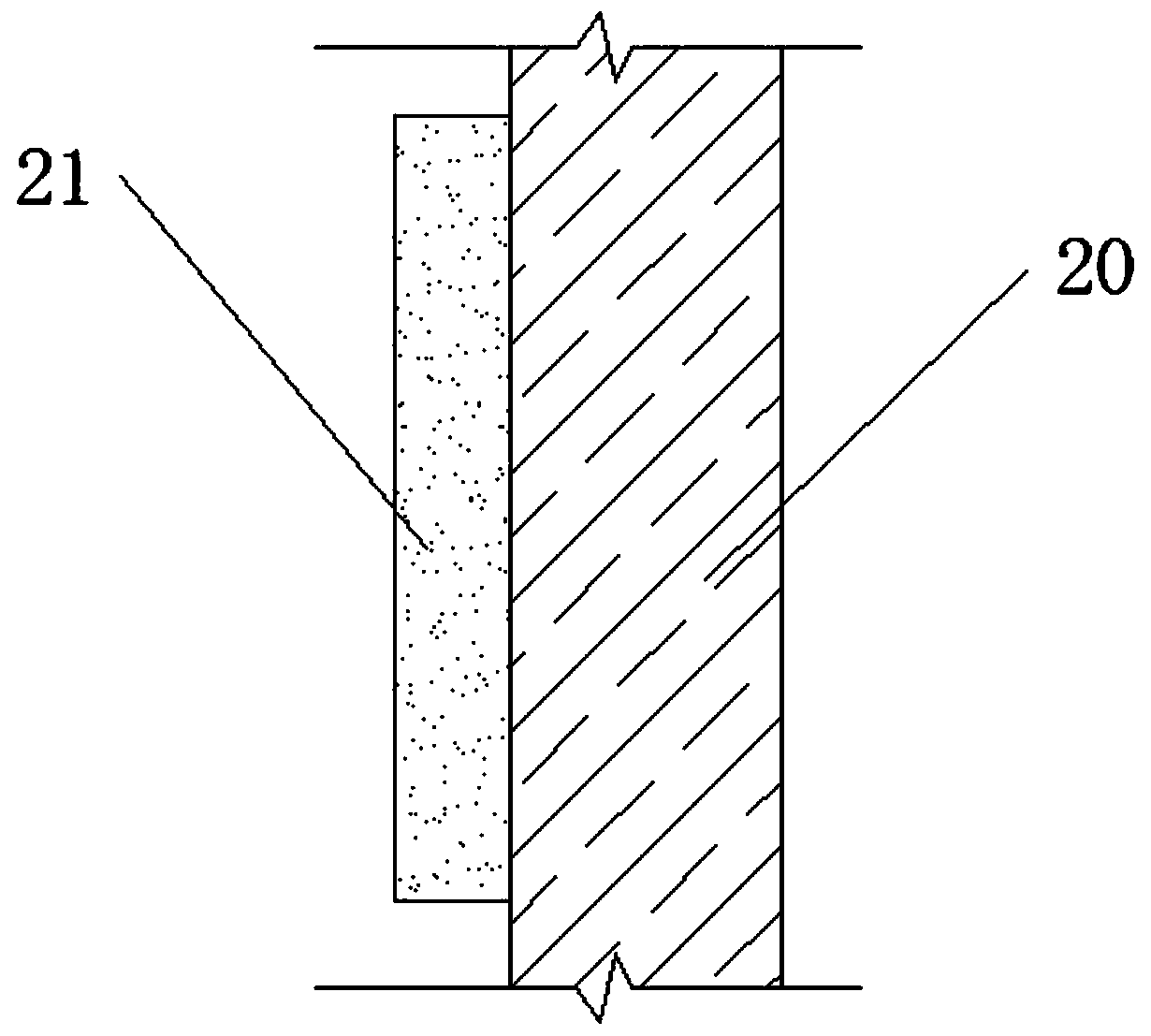

[0024] see Figure 1-5 , the present invention provides a technical solution: a length-adjustable support device for hoisting prefabricated components, including a base 1, a first rotating shaft 2, a driving gear 3, a first rotating rod 4, a first driven gear 5, a second Rotating shaft 6, connecting gear 7, second rotating rod 8, second driven gear 9, belt 10, rack 11, left connecting plate 12, right connecting plate 13, connecting block 14, groove 15, placement plate 16, card Groove 17, baffle plate 18, partition 19, bottom plate 20, magnet 21, connecting spring 22 and handle 23, the inside of base 1 is provided with first rotating shaft 2, and the outer wall of first rotating shaft 2 is fixed with driving gear 3, and drives The left side of the gear 3 is provided with a first driven gear 5, the inner wall of the first driven gear 5 is fixed with a first rotating rod 4, the right side of the driving gear 3 is meshed with a connecting gear 7, and the inside of the connecting g...

Embodiment 2

[0026] Further optimization on the basis of Embodiment 1: the inside of the base 1 is hollow, and the base 1 is connected with the first rotating shaft 2, the first rotating rod 4, the second rotating shaft 6 and the second rotating rod 8 with bearings, so that the first A rotating shaft 2, a first rotating rod 4, a second rotating shaft 6 and a second rotating rod 8 are more firmly connected to the inner wall of the base 1, thus ensuring the normal use of the device.

Embodiment 3

[0028] Further optimization on the basis of Embodiment 1: the left connecting plate 12 and the right connecting plate 13 are meshed with the first driven gear 5 and the second driven gear 9 through the rack 11 respectively, and the right end of the left connecting plate 12 is connected with the right The left end of plate 13 is all metal material, when turning driving gear 3 like this, can drive left connecting plate 12 and right connecting plate 13 to move simultaneously, thereby facilitates the placement of plate 16 above left connecting plate 12 and right connecting plate 13 The spacing can be adjusted to be suitable for the placement of components of different sizes, and at the same time, the left connecting plate 12 and the right connecting plate 13 can be fixed to the bottom plate 20 through the magnet 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com