Special in-situ rock core holder for high-density electrical parameter monitoring

A technology for holders and cores, applied in the field of in-situ core holders, can solve the problems that are not conducive to the complete preservation of precious cores, difficult to avoid cores, prolonging time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

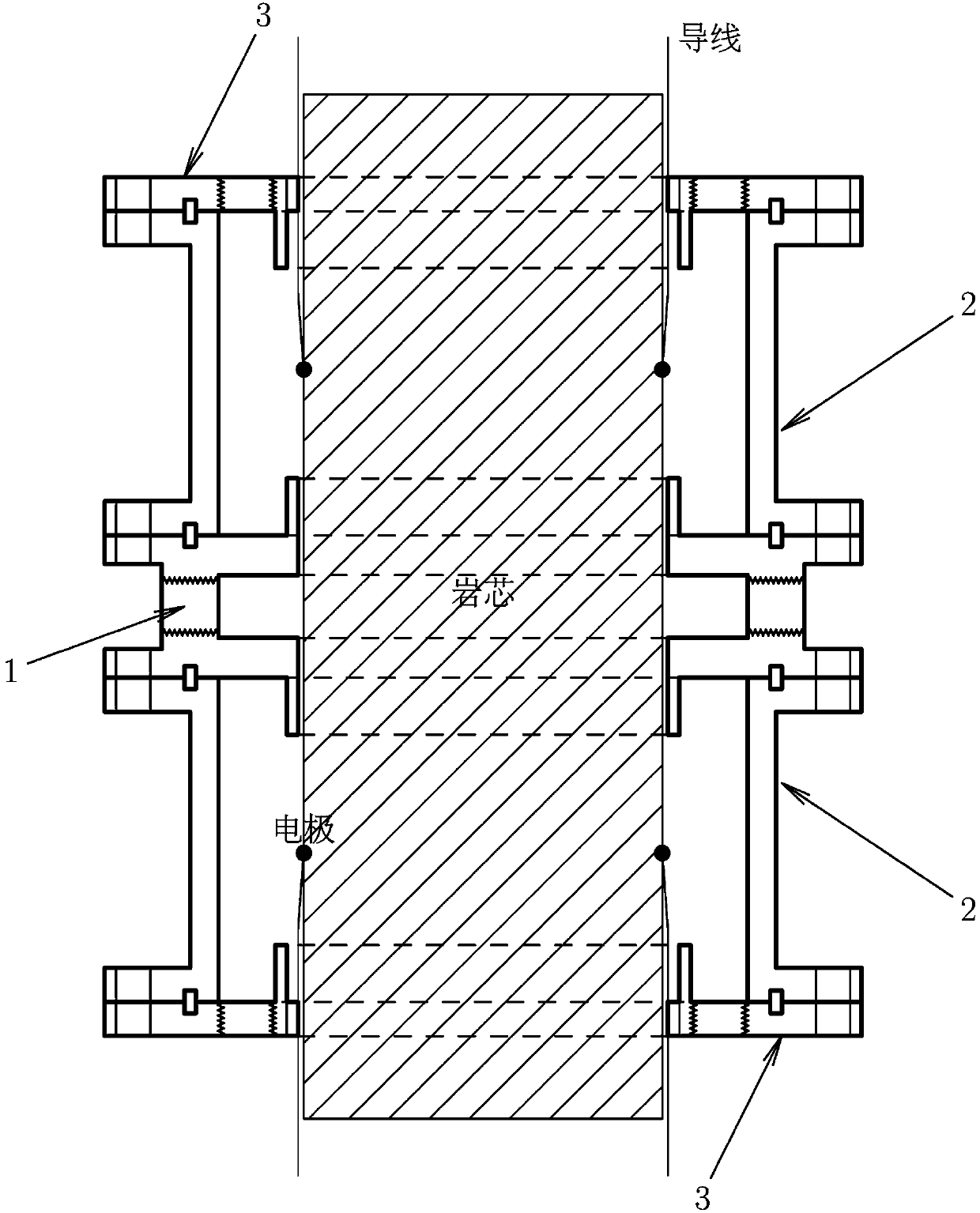

[0016] 1. Fix the long-length rock core to be tested on a certain support. The rock core can be placed horizontally or vertically.

[0017] 2. Install the central part 1 of the holder on a certain position of the rock core to be tested, and mark the positions where the electrodes need to be set on the rock cores on the left and right sides of the central part.

[0018] 3. Set up the electrodes on the rock core, select an insulated wire of appropriate thickness to connect to the electrode, extend the wire along the core axis to both sides and fix it.

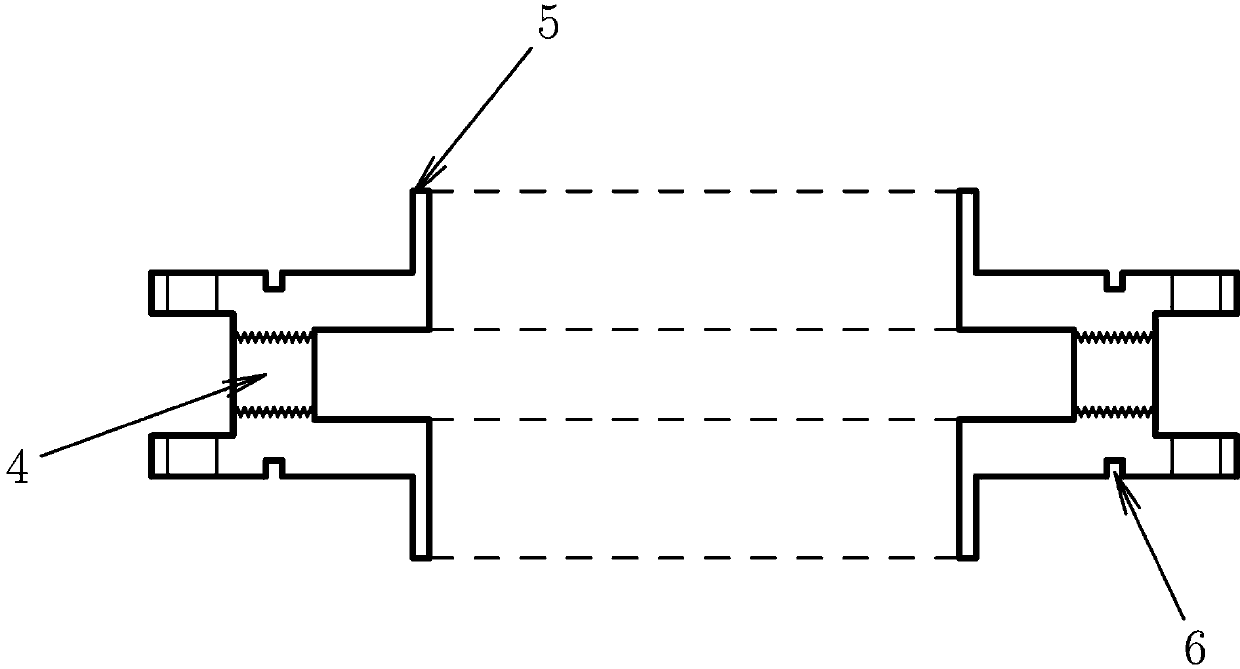

[0019] 4. Set the sleeves on the central part, and install the confining pressure cylinder 2.

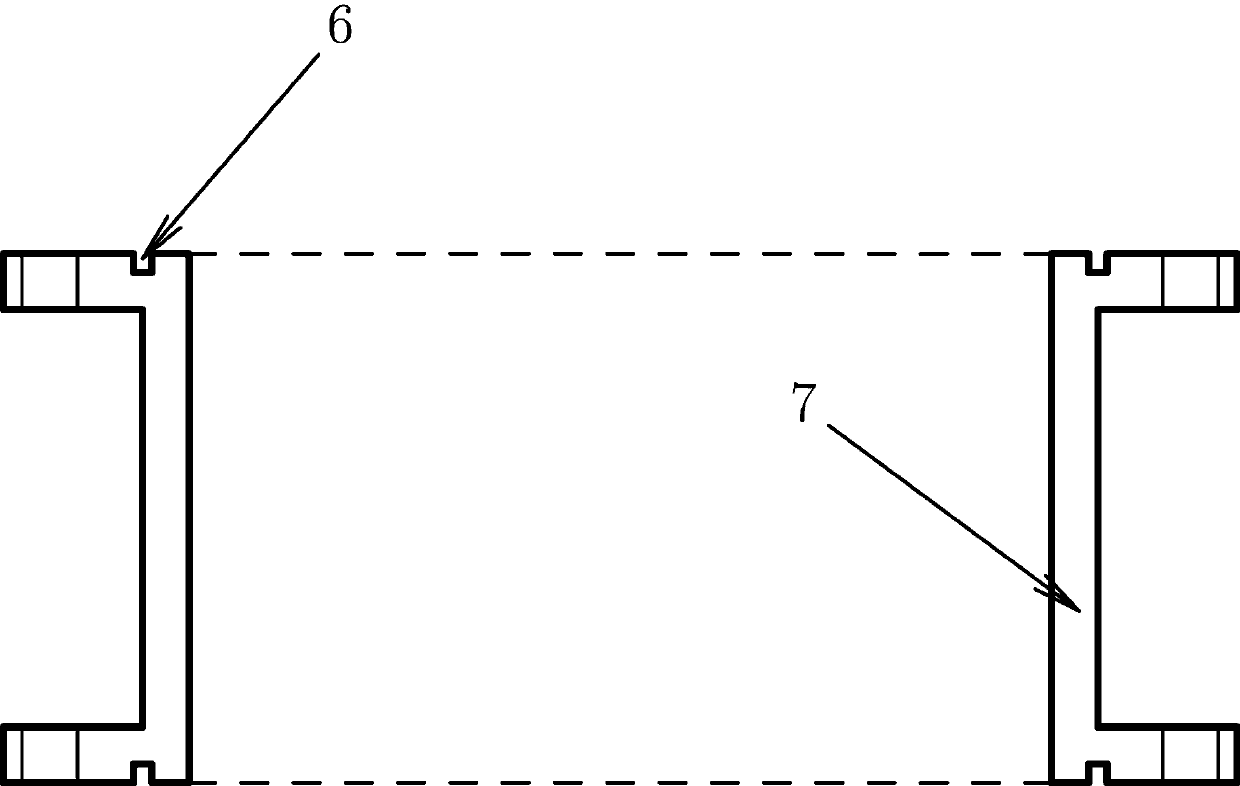

[0020] 5. Install the end piece 3, and at the same time put the sleeves on the end piece. The surface of the rock core after the electrodes and wires are installed will be uneven, which can be eliminated by injecting glue, so as to realize the dense connection between the rock core and the sleeve.

[0021]6. Connect and fix parts 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com