Workshop automatic lifting gate

A technology of automatic lift and gate, applied in door/window fittings, power control mechanism, arrangement of wings, etc., which can solve the problems of troublesome installation process, high requirements on wind load resistance and stability, and large windward area of the gate. , to prevent accidental falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

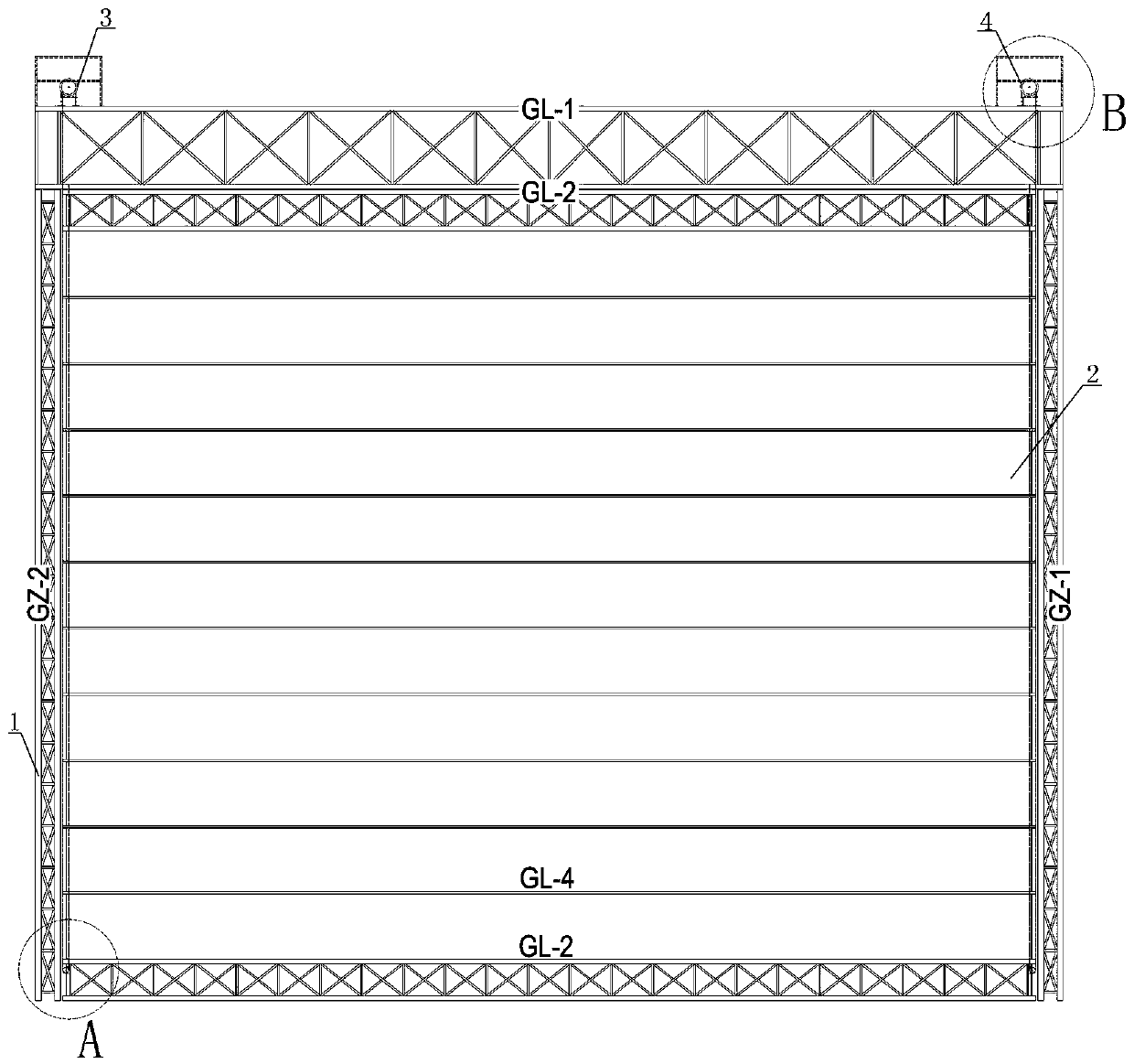

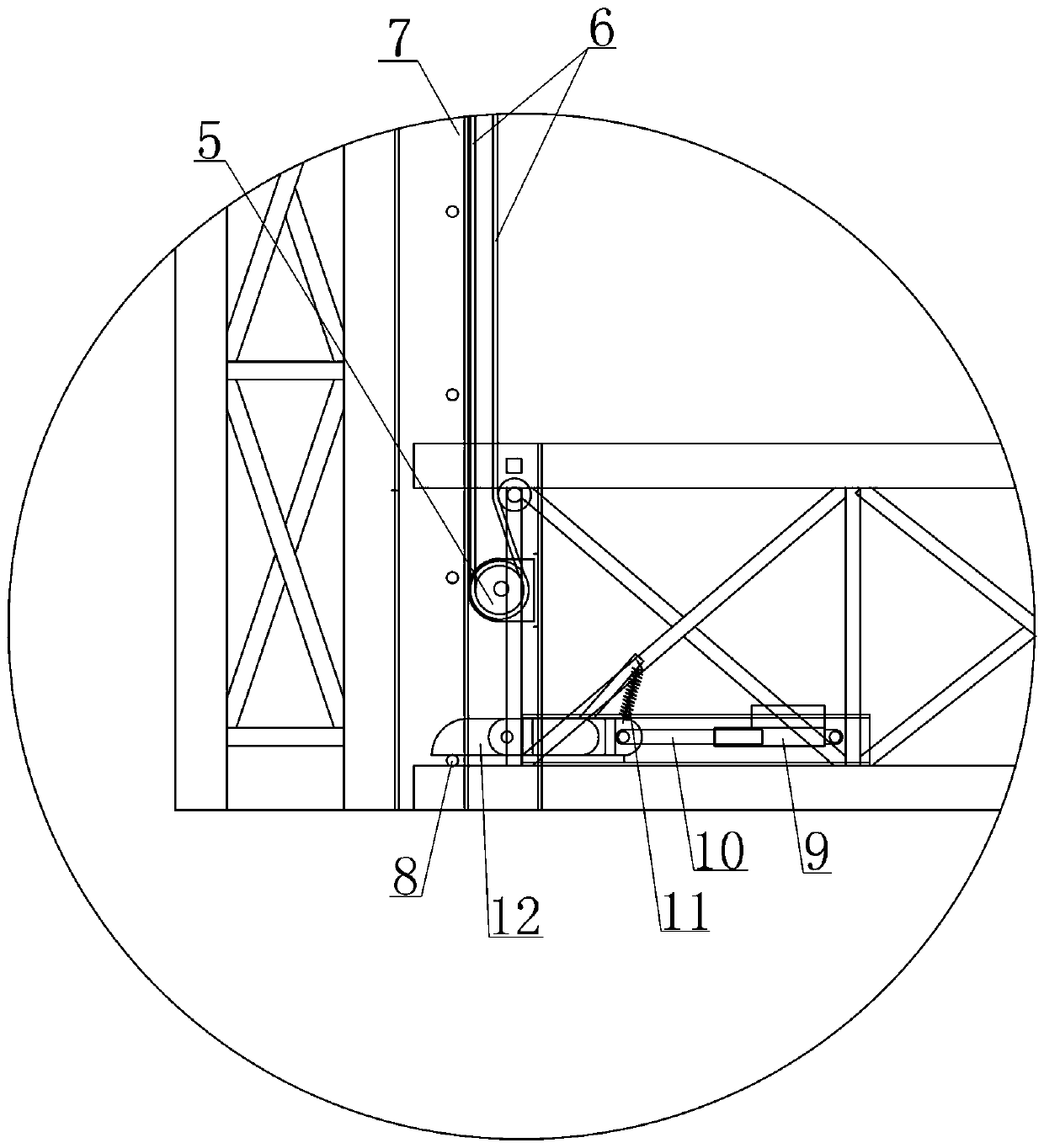

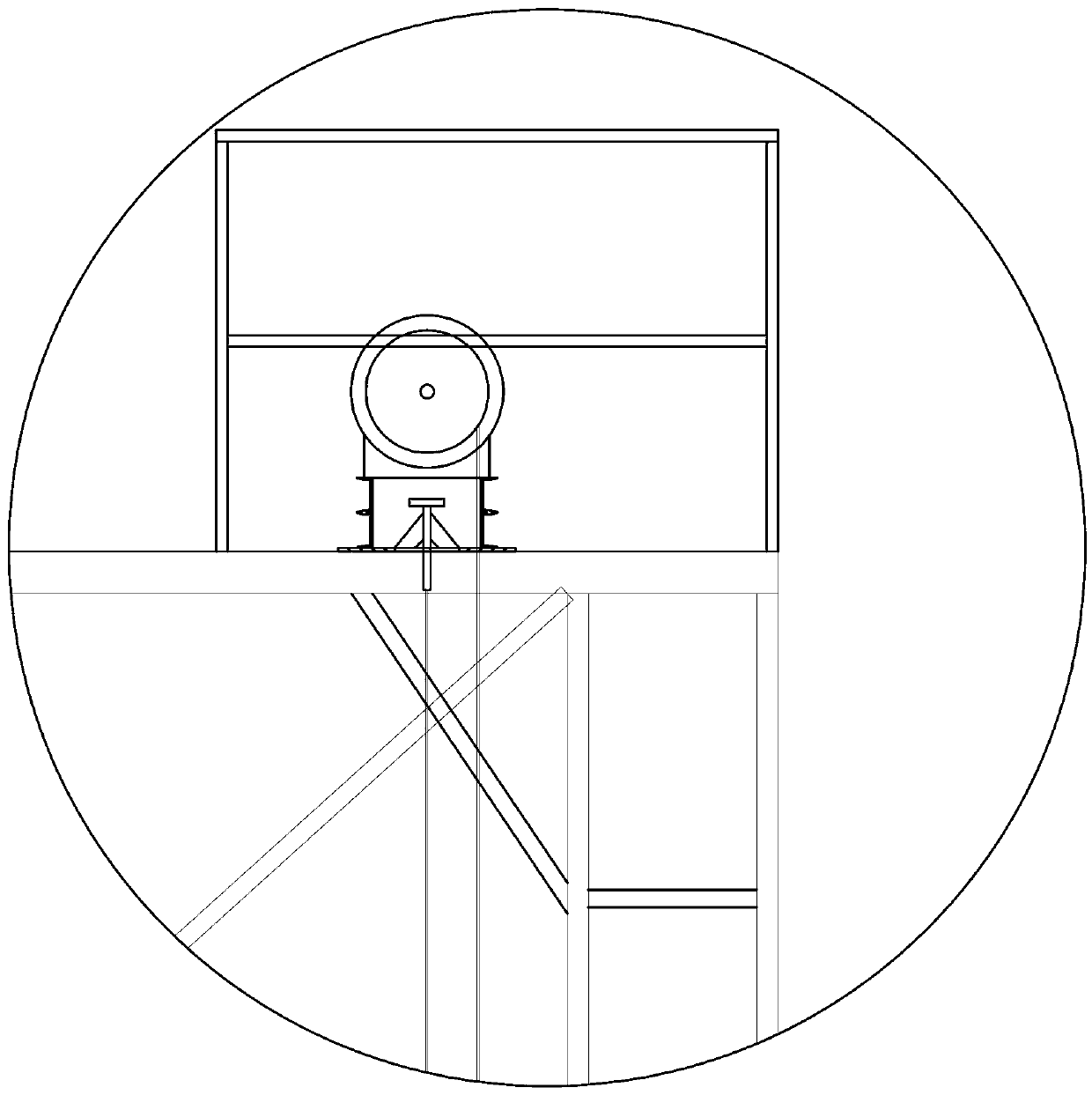

[0030] Such as figure 1 Shown is an automatic lifting gate for a factory building, which includes a door frame 1 and a door leaf 2 arranged in the door frame 1. The door leaf 2 is a lattice structure, and a hoist is arranged on the top of the door frame 1. The hoist is connected to the door leaf 2 through a pulley mechanism. The lower end is connected, and the hoist realizes the upward opening and downward closing of the door leaf through the pulley mechanism.

[0031] Specifically, the hoist includes a first hoist 3 and a second hoist 4 respectively arranged on the left and right sides of the top of the door frame 1. The pulley mechanism is divided into a first pulley mechanism and a second pulley mechanism. A fixed pulley block 5 below the hoist 3 and positioned at the bottom of the door leaf 2, the first hoist 3 is connected with the fixed pulley block 5 through a traction rope 6; Pulley block, the second hoisting machine 4 is connected with fixed pulley block by traction ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap