Intelligent ore dry separator

A dry sorting machine and intelligent technology, applied in the field of mineral dry sorting, can solve the problems that the user experience and dry sorting effect need to be improved, the specific structure of the equipment system is not reasonable enough, and the auxiliary system design is not complete enough, etc., so as to achieve complete dust removal and protection functions, Good dry selection effect and stable dry selection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

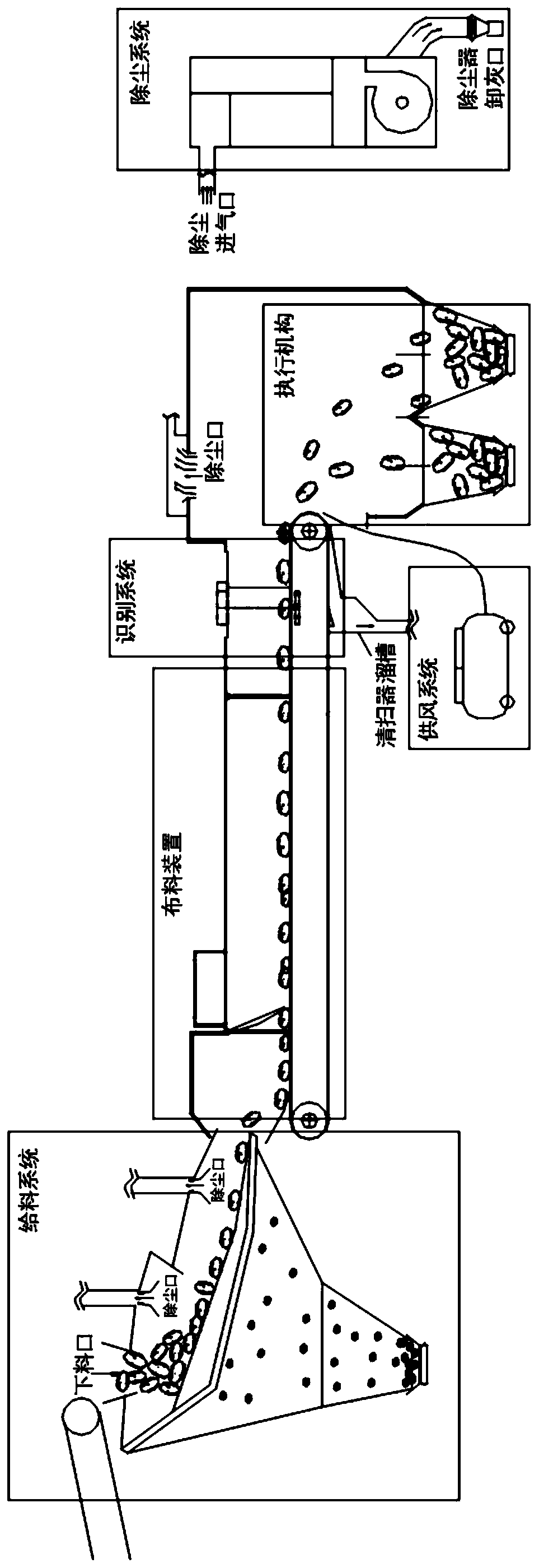

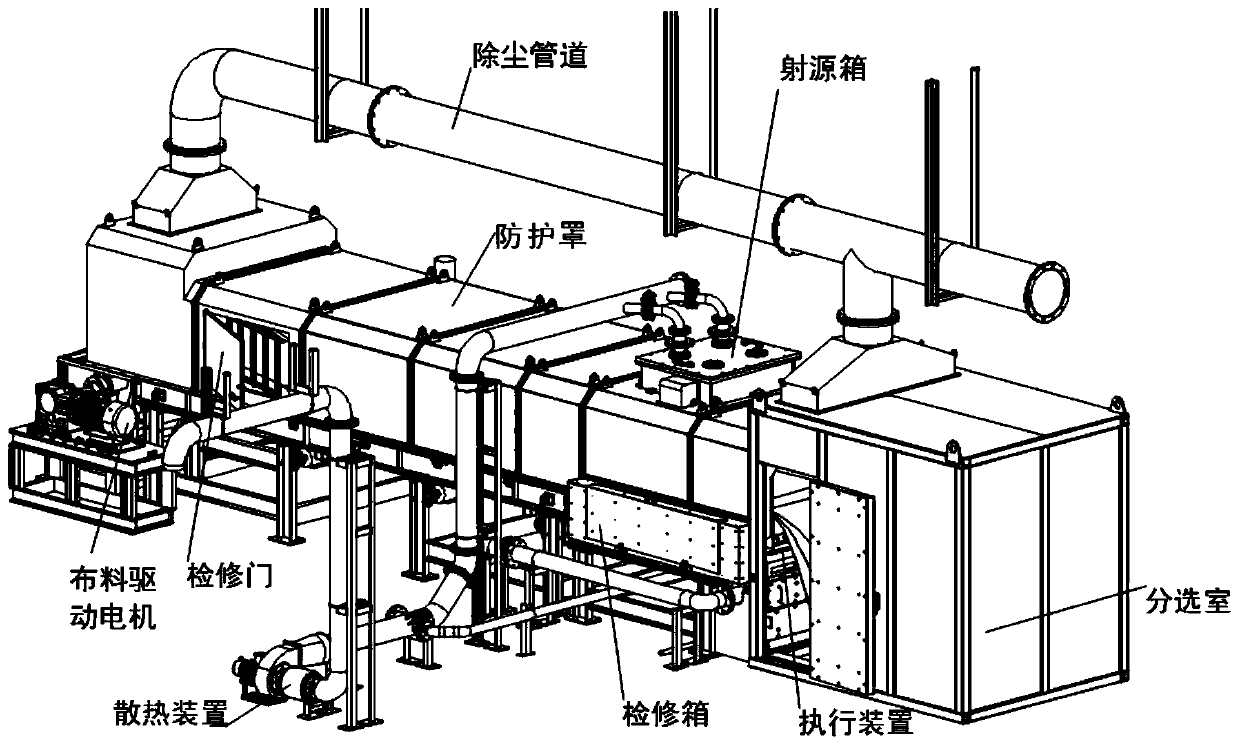

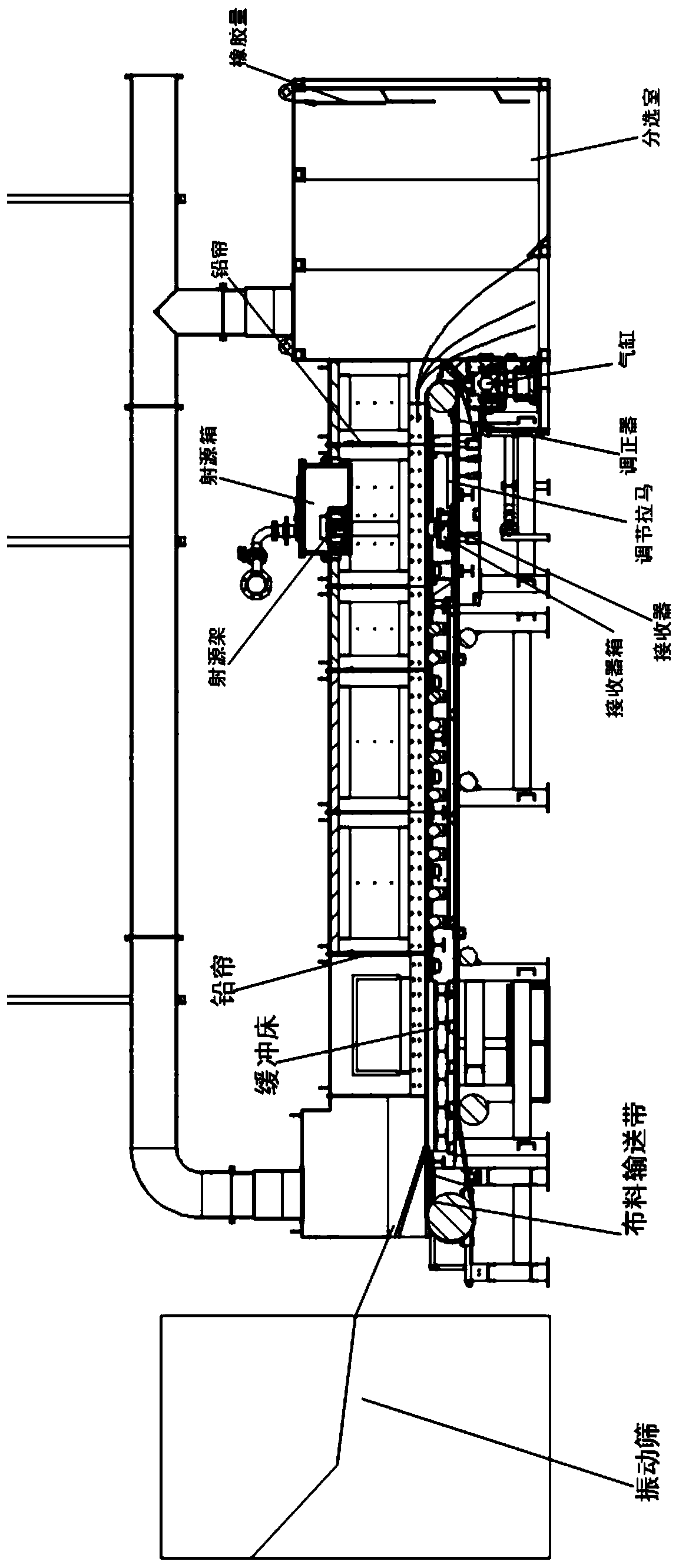

[0018] see Figure 1-Figure 5 , an ore intelligent dry separation machine, including: a feeding system, a material distribution device, an identification system, an air supply system, an actuator, a dust removal system and a heat dissipation device, the feeding system includes a discharge port and a dust removal port, and the identification system is below A sweeper chute is provided, and a dust removal port is provided above the execution structure, and the dust removal port is connected with the dust removal air inlet of the dust removal system, and a dust discharge port of the dust collector is provided below the dust removal system, and the heat dissipation device is connected with the identification system. In actual operation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com