Aluminum product device for continuously casting blanks

A product and billet technology, applied in the field of equipment for continuous casting billets of aluminum products, can solve the problems of complex design, wear and tear of tensioner rims, difficult maintenance, etc., achieve reasonable and precise structural design, independent water cooling system, and eliminate potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

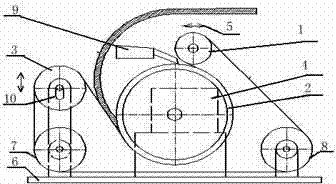

[0013] A device for continuous casting billets of aluminum products, such as figure 1 As shown: it includes a crystallization wheel 2 and a pinch wheel 1 parallel to each other in the axial direction. There is a pouring chute 9 between the crystallization wheel 2 and the pinch wheel 1. A steel reference plane 6 is fixed, and on the side of the above-mentioned crystallization wheel 2 above the steel reference plane 6, there are fixed rising tensioner 3 and lower tensioner 7 parallel to the axial direction of the above-mentioned crystallization wheel 2 and with a certain distance. 1. On the other side of the above-mentioned crystal wheel 2, there are fixed side tension wheels 8 that are symmetrically distributed with respect to the crystal wheel 2 and the lower tension wheel 7, the above-mentioned crystal wheel 2, the compression wheel 1, the tension wheel 3, the Cooperate with steel band on the tensioner 7 and the tensioner 8 under the side.

[0014] Cooperate with cylinder 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com