A dressing method for a grinding wheel interpolation dressing mechanism

A dressing mechanism and grinding wheel technology, which is applied to the parts of grinding machine tools, abrasive surface adjustment devices, metal processing equipment, etc., can solve problems such as difficulties in realization, and achieve the effect of low mechanical energy consumption and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

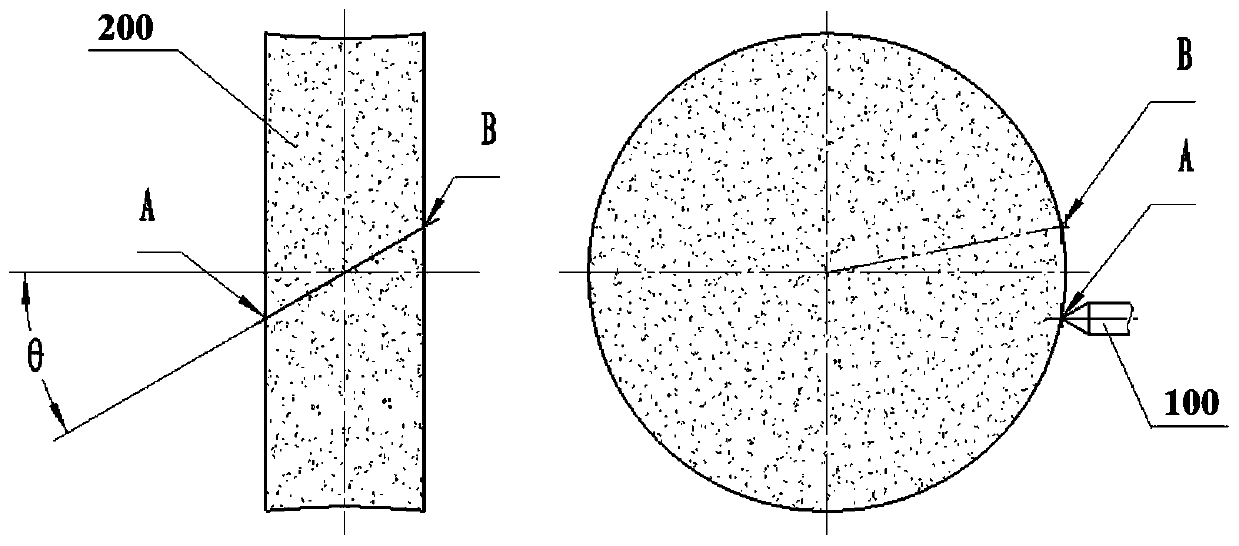

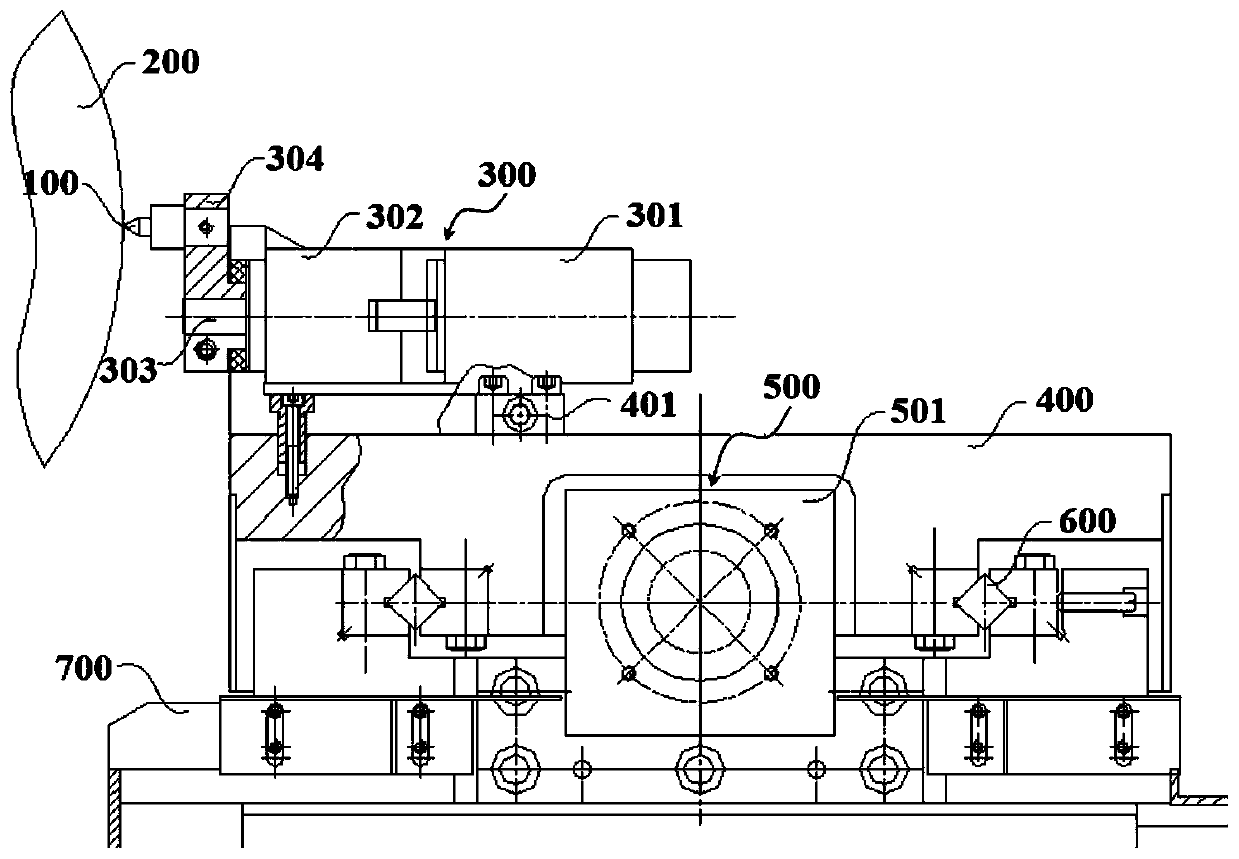

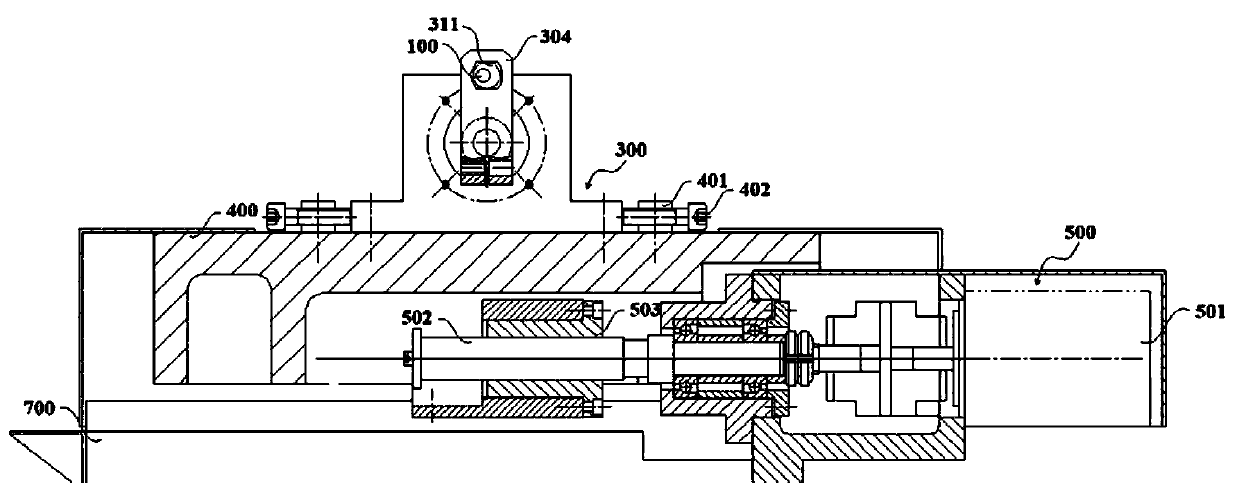

[0055] combine figure 2 and image 3 , a kind of emery wheel interpolation dressing mechanism of the present embodiment, comprises diamond pen 100, grinding wheel 200, rotating unit 300, and wherein diamond pen 100 is fixedly installed on the rotating arm 304 of rotating unit 300, and this rotating arm 304 and rotating unit 300 The rotating shaft 303 of the servo motor 301 is connected. The rotation of the servo motor 301 drives the rotating arm 304 to rotate, and then drives the diamond pen 100 to rotate, thereby trimming the grinding wheel 200 on the workbench, and the entire rotating unit 300 is fixedly installed on the upper pallet 400, which is located on the on the workbench.

[0056] The diamond pen 100 is controlled by the servo motor 301 with the rotating shaft 303 as the center of a circle, and the distance between the central axis of the diamond pen 100 and the central axis of the rotating shaft 303 is used as a radius to rotate. This rotation can be a circular r...

Embodiment 2

[0064] combine figure 2 , a grinding wheel interpolation dressing mechanism of this embodiment is basically the same as that of Embodiment 1, the difference is that: this embodiment is equipped with a longitudinal sliding guide rail 600 on the lower pallet 700, and is provided with a sliding rail on the upper pallet 400. The longitudinal sliding guide rail 600 cooperates with the slideway to facilitate the longitudinal feed motor 501 to control the axial movement of the upper supporting plate 400 along the grinding wheel 200 .

[0065] In this embodiment, in order to further ensure the smooth operation of the diamond pen 100, a reducer 302 is integrated on the servo motor 301, and the servo motor 301 and the reducer 302 cooperate to drive the diamond pen 100 to swing.

[0066] As a preference, the reducer 302 in this embodiment adopts a planetary reducer with high transmission efficiency, low noise and long life.

[0067] The rotating arm 304 in this embodiment can be instal...

Embodiment 3

[0071] combine figure 2 , a grinding wheel interpolation dressing mechanism of this embodiment is basically the same as that of Embodiment 2, the difference is that: the vertical sliding guide rail 600 in this embodiment is horizontally arranged on the upper surface of the lower pallet 700, and the slideway is arranged on the upper surface On the lower surface of the supporting plate 400, the two cooperate with each other to facilitate the movement of the upper supporting plate 400.

[0072] In addition, in this embodiment, holes are provided on the bottom surface of the casing of the servo motor 301 and the upper supporting plate 400, and the bolts pass through the two holes to fix the servo motor 301 on the upper supporting plate 400, that is, the servo motor 301 is vertically fixed. The rotating unit 300 is fixed on the upper support plate 400 through double fixing in horizontal and vertical directions.

[0073] combine Figure 4 , Figure 5 and Figure 6 , the fine-tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com