Dressing method of double circle tangent interpolation dressing device

A dressing device and interpolation technology, applied in the direction of abrasive surface adjustment devices, grinding machine parts, metal processing equipment, etc., can solve problems such as difficulties in realization, and achieve the effects of easy operation, simple structural design, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

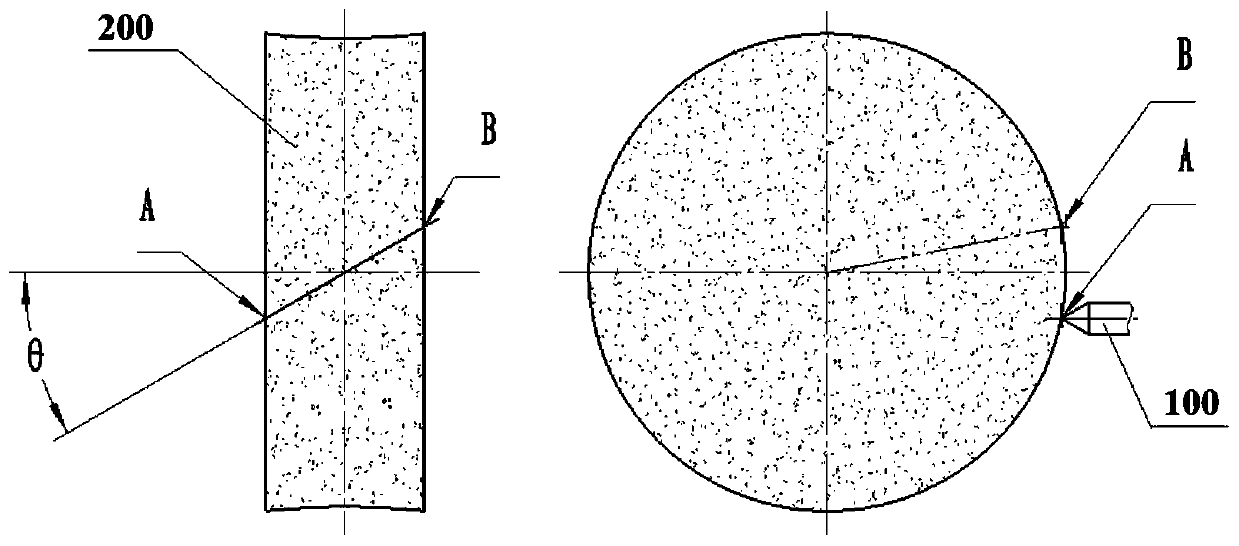

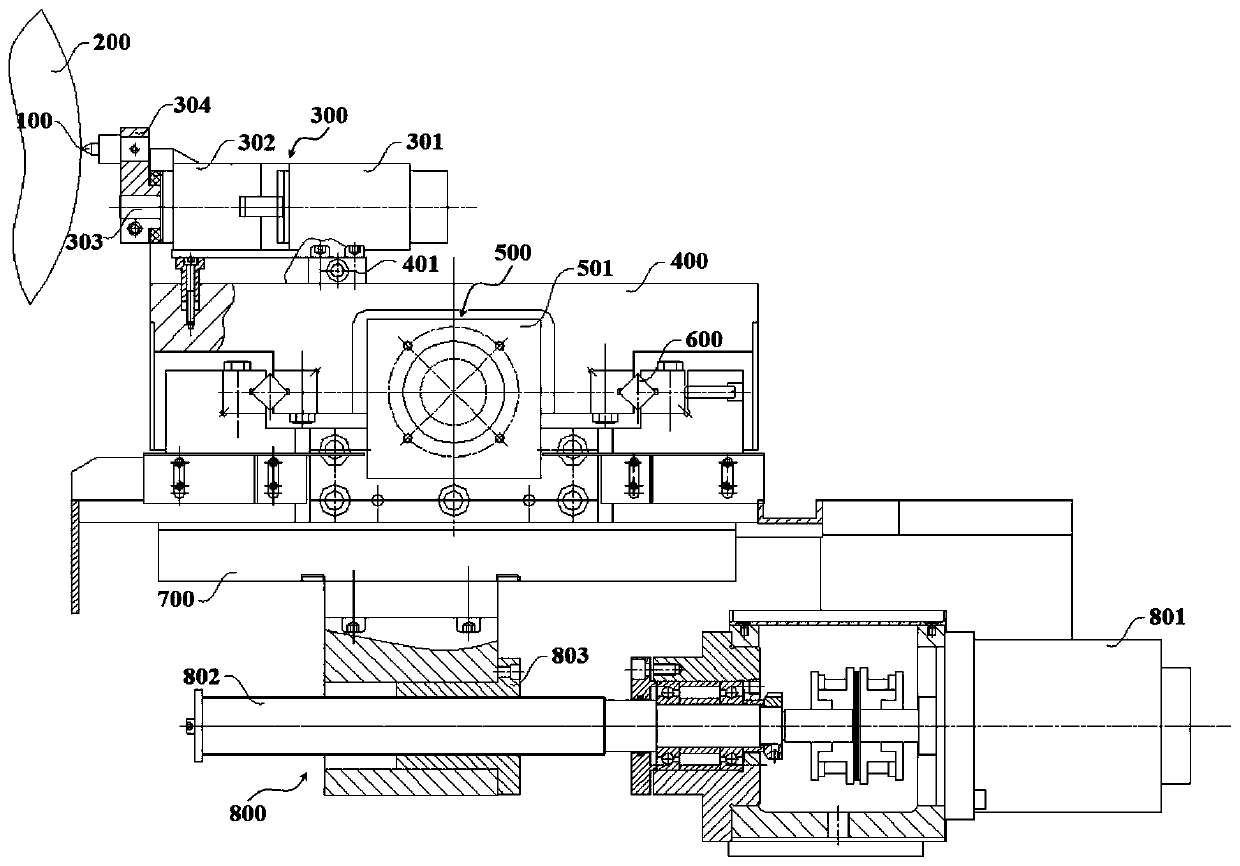

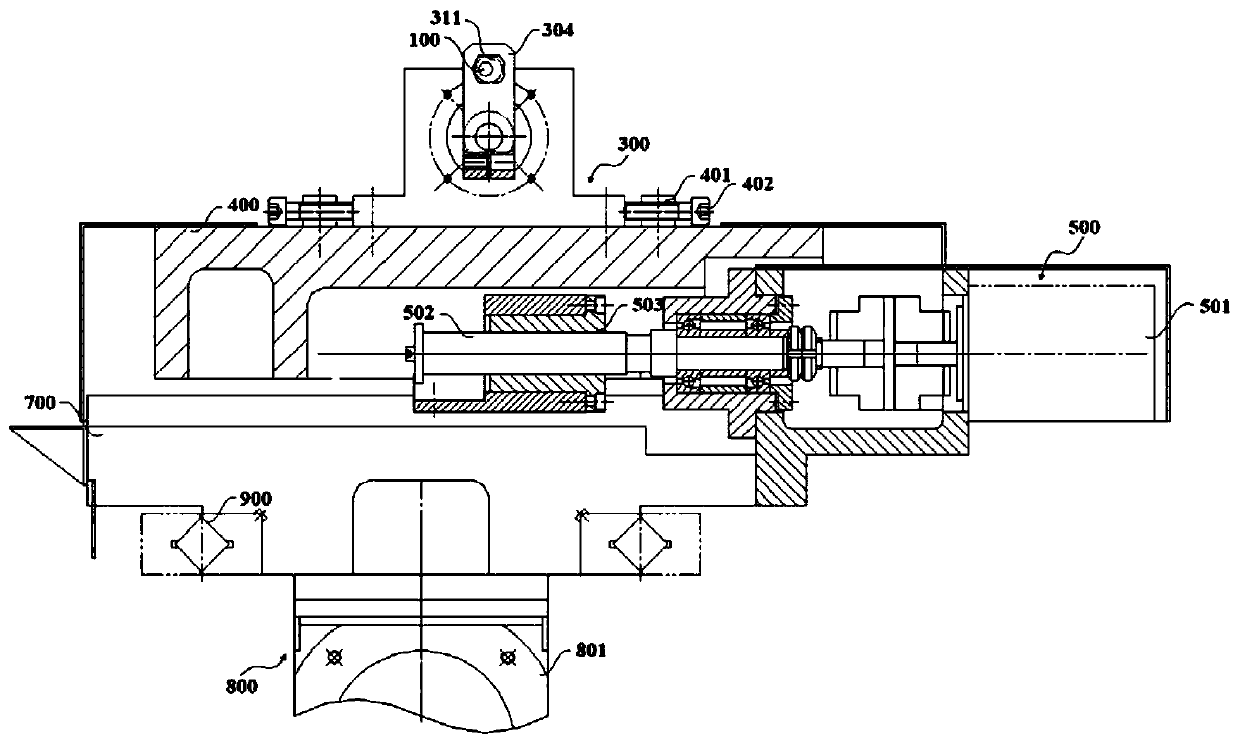

[0057] combine figure 2 and image 3 , a kind of double-circle tangential interpolation trimming device of the present embodiment comprises a diamond pen 100 and a rotating unit 300, wherein the diamond pen 100 is fixedly mounted on the rotating arm 304 of the rotating unit 300, and the rotating arm 304 and the rotating unit 300 The rotating shaft 303 of the servo motor 301 is connected. The rotation of the servo motor 301 drives the rotating arm 304 to rotate, and then drives the diamond pen 100 to rotate, thereby dressing the grinding wheel 200 on the workbench. The entire rotating unit 300 is fixedly installed on the upper supporting plate 400, and the upper supporting plate 400 is installed on the workbench.

[0058] The diamond pen 100 is controlled by the servo motor 301 with the rotating shaft 303 as the center of a circle, and the distance between the central axis of the diamond pen 100 and the central axis of the rotating shaft 303 is used as a radius to rotate. Th...

Embodiment 2

[0066] combine figure 2 and image 3 , a double-circle tangential interpolation trimming device in this embodiment is basically the same as that in Embodiment 1, except that the longitudinal feed unit 500 in this embodiment includes a longitudinal feed motor 501, a first ball screw 502 and the first screw pair 503, wherein the longitudinal feed motor 501 is connected with the first ball screw 502 through a coupling; the first screw pair 503 is installed on the first ball screw 502, and the first screw The rod pair 503 can move on the first ball screw 502, and the first screw rod 503 is fixedly connected with the upper supporting plate 400 by screws.

[0067] When the longitudinal feed motor 501 is started, the first ball screw 502 rotates, and the first screw pair 503 converts the rotational motion into a linear motion, that is, the first screw pair 503 moves on the first ball screw 502, and then drives The upper pallet 400 moves. Since the longitudinal feed motor 501 in t...

Embodiment 3

[0078] combine figure 2 and image 3 , a double-circle tangential interpolation trimming device of this embodiment is basically the same as that of Embodiment 2, the difference being that the longitudinal sliding guide rail 600 in this embodiment is horizontally arranged on the upper surface of the lower pallet 700, and the slideway It is arranged on the lower surface of the corresponding upper pallet 400 , and the two cooperate with each other to facilitate the movement of the upper pallet 400 . The design of the horizontal sliding guide rail 900 is basically the same as that of the longitudinal sliding guide rail 600. The horizontal sliding guide rail 900 is horizontally arranged on the upper surface of the workbench, and the slideway is arranged on the lower surface of the corresponding lower supporting plate 700. The two cooperate with each other. , to facilitate the movement of the lower pallet 700.

[0079] like Figure 4 and Figure 5 As shown, in this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com