A Method for Predicting the High-low Cycle Combined Fatigue Life of Aeroengine Turbine Blades

A fatigue life prediction, aero-engine technology, used in engine testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as inability to accurately predict materials and turbine blade life estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0034] The composite fatigue life prediction under the high and low cycle composite fatigue loads to be carried out by the present invention, the specific implementation steps are as follows:

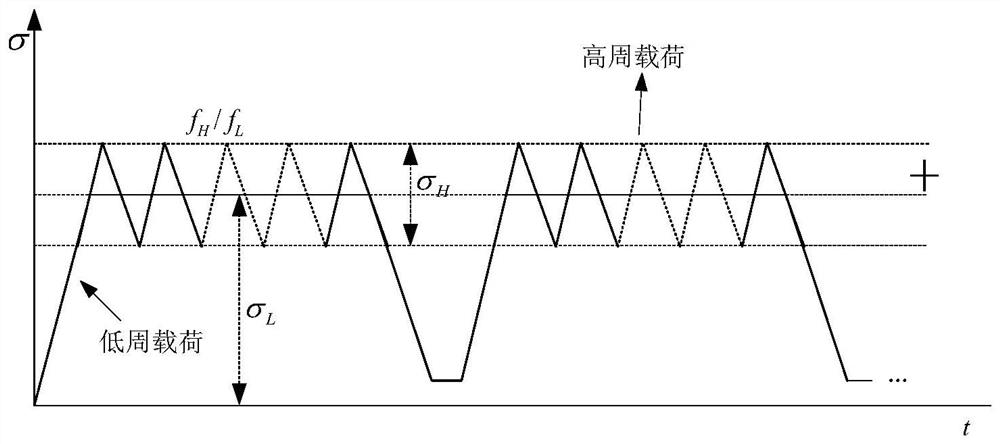

[0035] Step 1. For the high-low cycle composite fatigue test, the traditional linear cumulative damage model (Miner’s law) is introduced into the high-low cycle composite fatigue damage. When the amplitude of the high-low cycle composite load is constant, the damage of a composite load block is

[0036]

[0037] Among them, N HCF is the high-cycle fatigue life corresponding to high-cycle cyclic loading, N LCF is the low cycle fatigue life corresponding to the low cycle load, and n is the freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com