Channel steel supports with flow blocking sheet structure for fixing heat preservation layer outside reactor

A technology of channel steel bracket and insulation layer, which is applied in the field of reactor engineering, can solve the problems of reducing material durability and heat leakage, and achieve the effect of reducing local excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

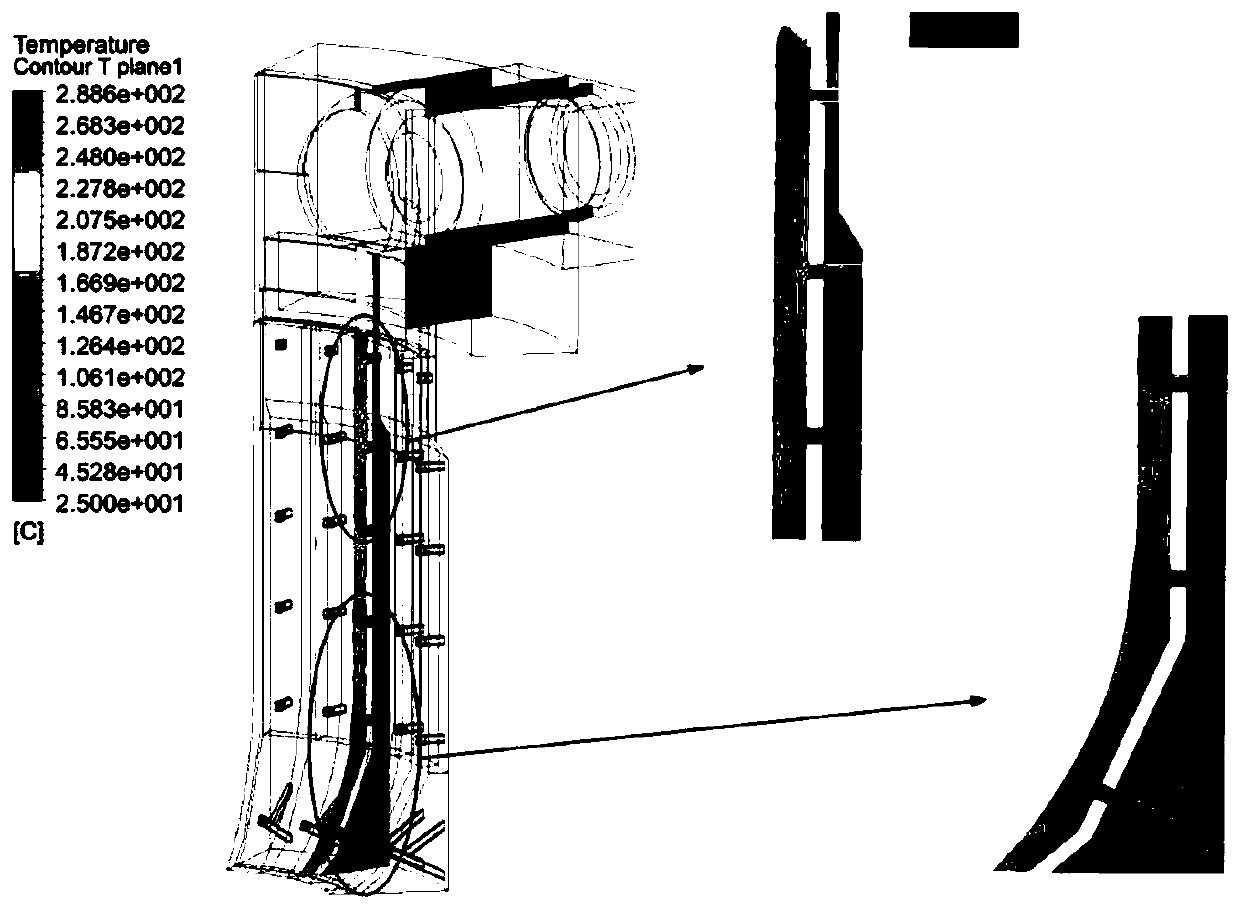

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0014] A channel steel bracket with a baffle structure for fixing the thermal insulation layer outside the reactor;

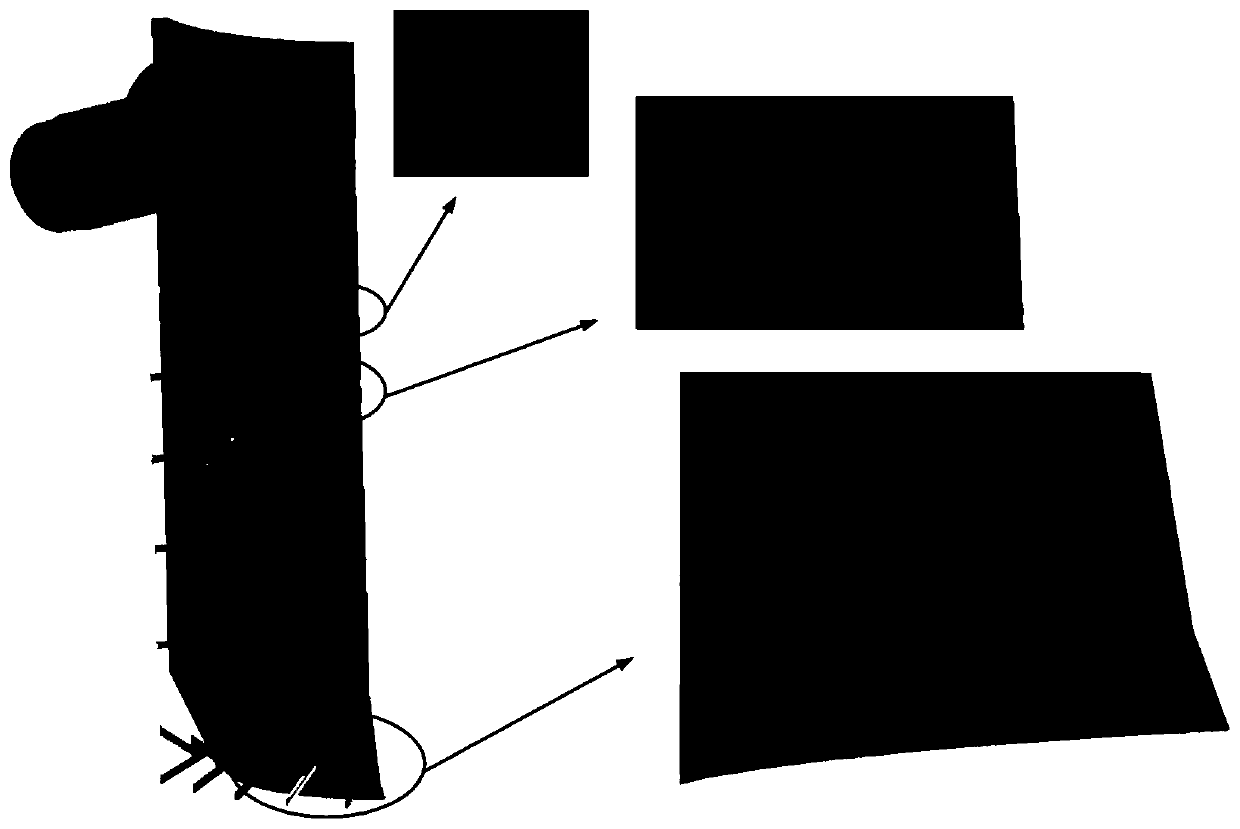

[0015] As stated in the background technology, the pores existing between the existing insulation layer and the channel steel support are as follows: figure 1 As shown, one end of the channel steel bracket is fixed to the cement wall of the pile pit, and the other end is inserted into the hole of the insulation layer structure to support the insulation layer. For the convenience of installation, the aperture of the insulation layer is always slightly larger than the channel steel section structure. The groove in the middle of the channel steel bracket together forms the pore structure at the connection between the insulation layer and the channel steel.

[0016] The installation and support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com