Method and system for processing water-immersed workpieces with dual lasers

A dual-laser, workpiece technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of flat incision, reduced thermal impact, and reduced thermal impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

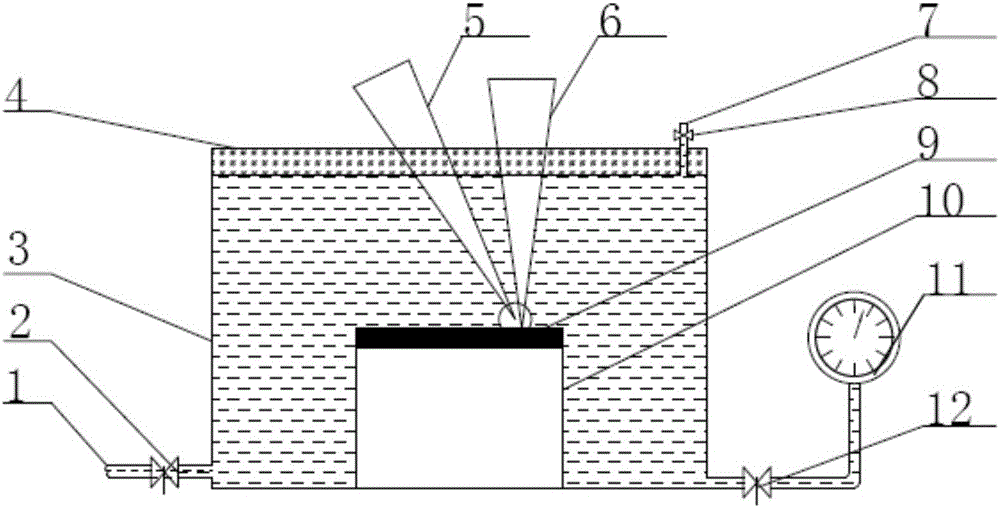

[0025] System embodiment of dual laser processing water immersion workpiece

[0026] The structure of the system embodiment of this double laser processing water immersion workpiece is as follows figure 1 As shown, the lower part of the water tank 3 of this example has a water inlet 1, and a water inlet valve 2 is installed on the water inlet, and the water tank 3 has a transparent glass top cover 4 that can seal its top. Install exhaust valve 8 on it. The water tank 3 is connected with a pressure measuring tube, and the pressure measuring tube is connected with a water pressure gauge 11 through a pressure measuring valve 12 . When the water tank 3 was filled with water, the water inlet valve 2, the exhaust valve and the pressure measuring valve 12 were all opened. When the system is working, the water inlet valve 2, the exhaust valve 8 and the pressure measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com