Welding-free LED filament bulb

A technology for LED filaments and bulb lamps, which is applied to lighting devices, light sources, and light source fixation. It can solve problems such as filament and stem offset, virtual welding, and easily damaged LED filaments, and achieve the effect of preventing filaments from loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

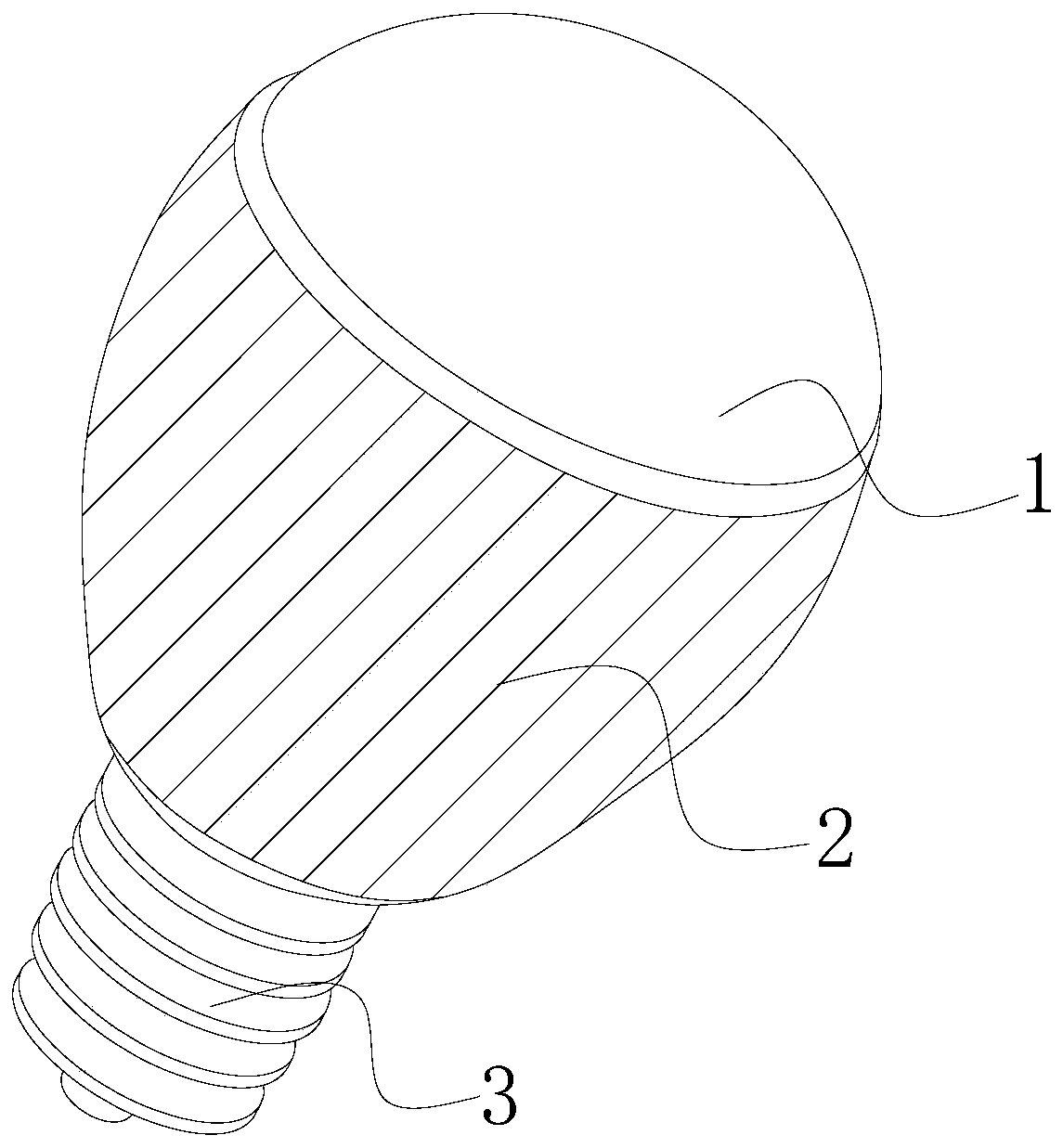

[0025] see Figure 1-Figure 6 , the present invention provides a solder-free LED filament bulb lamp, the structure of which includes a lampshade 1, a stem 2, and a mounting plate 3, the lampshade 1 is connected to the mounting plate 3, the stem 2 is arranged inside the lampshade 1, The lampshade 1 is set up in a bulb shape, the stem 2 is fixedly connected with the mounting plate 3, and the mounting plate 3 is set up in a spiral shape.

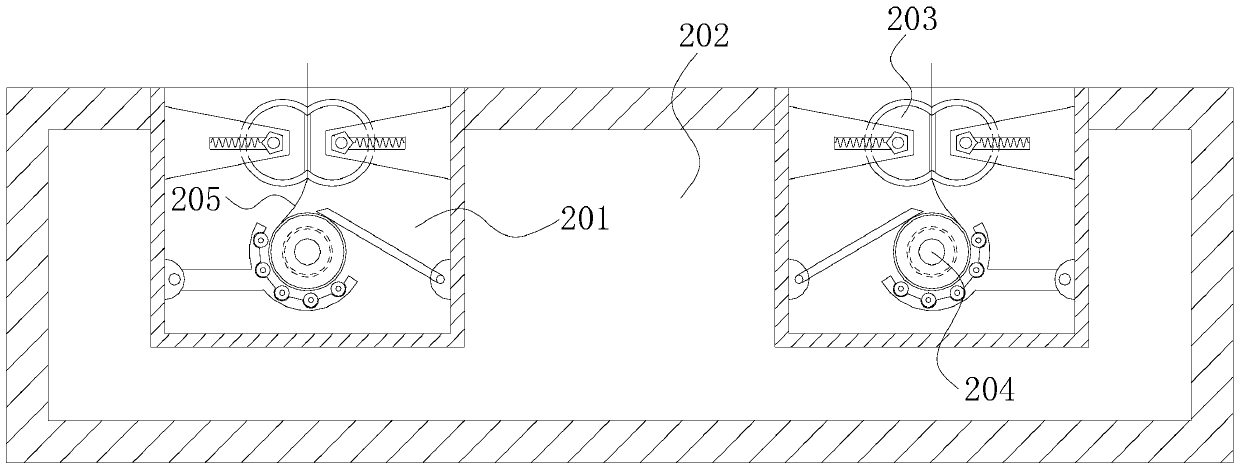

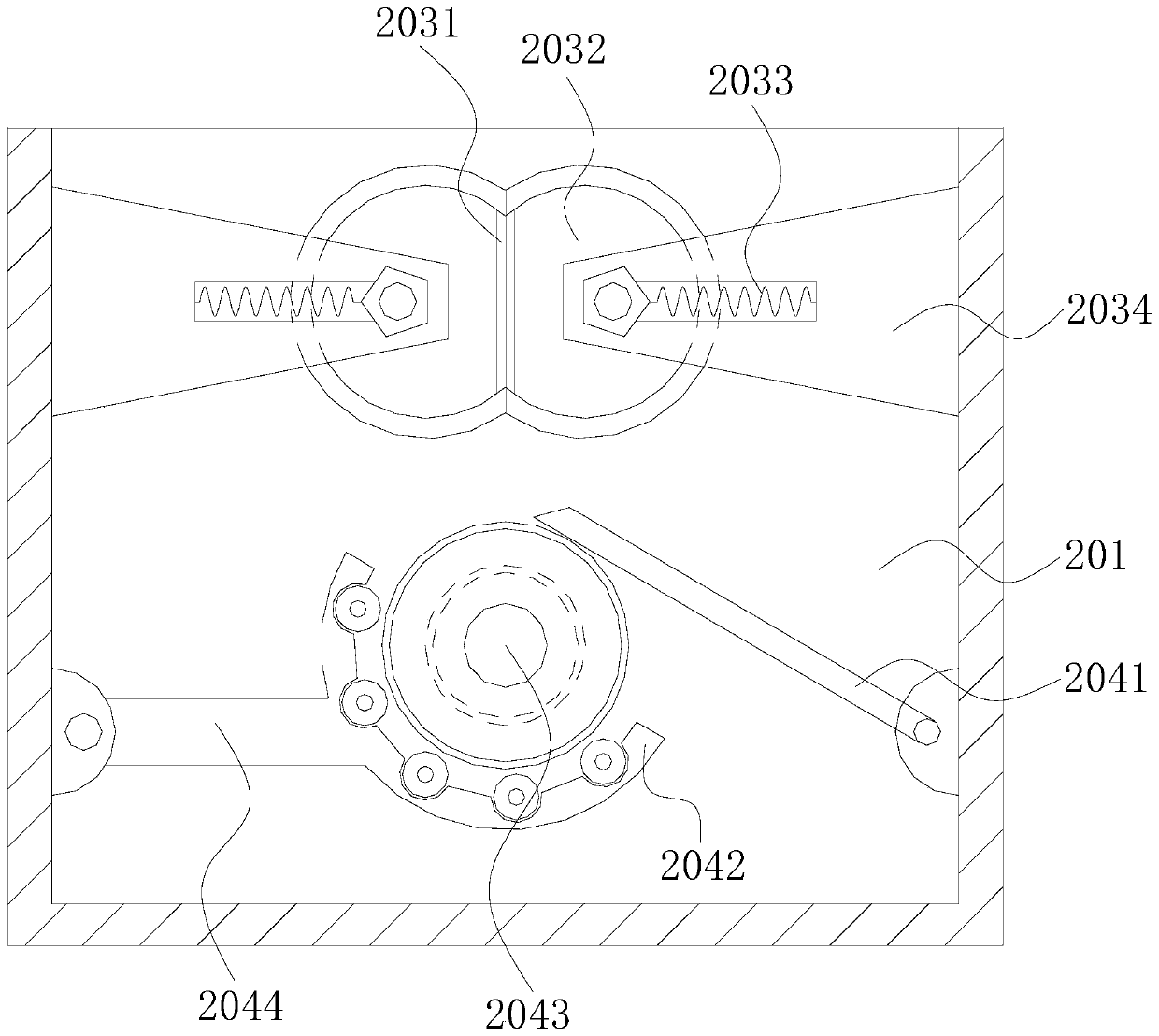

[0026] The stem 2 is composed of a filament fixing cavity 201, a working cavity 202, a connecting mechanism 203, a fixing mechanism 204, and a filament 205. The filament fixing cavity 201 is provided with two and set up in a symmetrical structure. The cavity 201 is installed in the working cavity 202, the connecting mechanism 203 and the fixing mechanism 204 are both arranged in the filament fixing cavity 201, the connecting mechanism 203 is located in the north direction of the fixing mechanism 204, and the filament 205 and the connecting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com