Leak-free and non-directional fuel tank for fuel cells

A non-directional, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as liquid fuel leakage, technical difficulties, and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] To further illustrate the present invention, the following examples are cited.

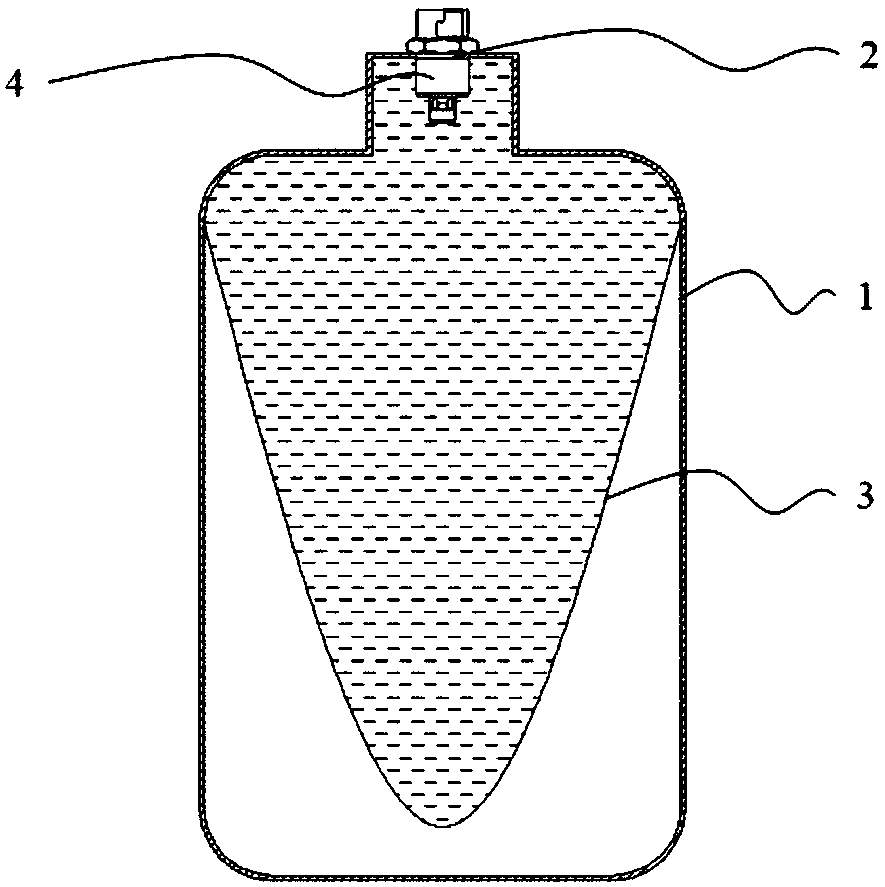

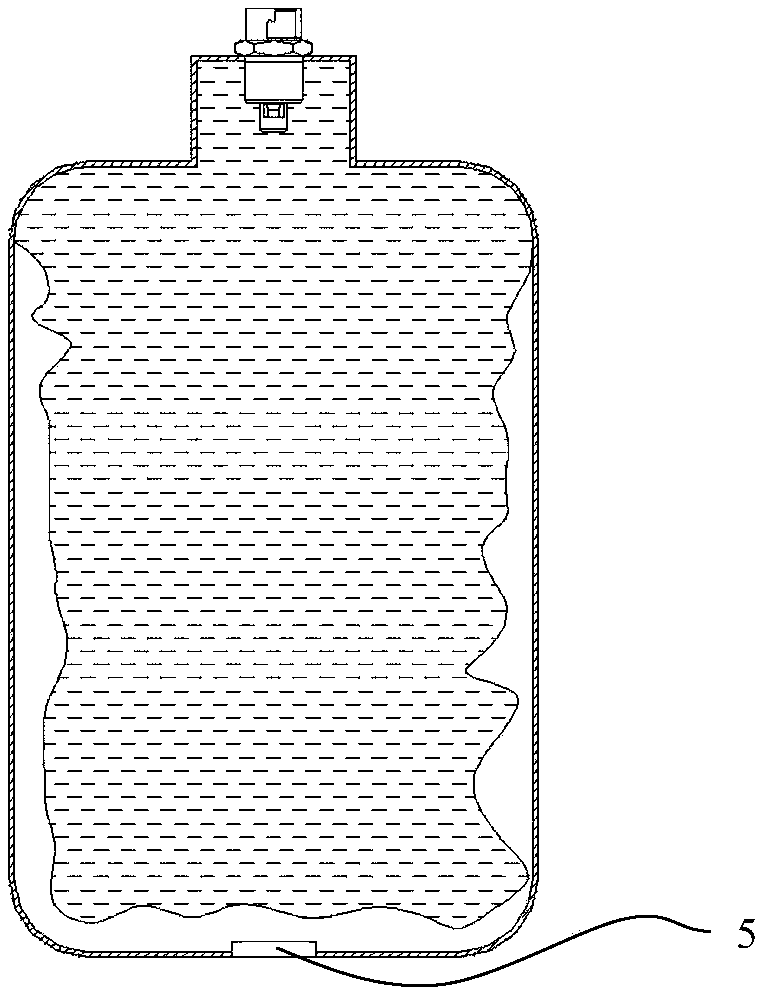

[0026] A non-leakage, non-directional fuel tank for fuel cells, which is provided with a closed hollow rigid tank body 1, a liquid outlet 2 is opened on the upper end of the tank body 1, and a flexible material with an open upper end and a closed lower end is arranged inside the tank body 1 A cylindrical liner 3 of elastic material, the upper opening end of the inner liner 3 is airtightly connected with the inner wall surface of the upper part of the tank body 1, and the liquid outlet 2 is located in the area surrounded by the upper opening end of the inner liner 3 . A joint 4 with a shut-off valve function is provided at the liquid outlet 2 outside the tank body 1 .

[0027] Connect the CPC brand NS4D42002 universal interface with the paired NS4D17002 universal interface, and connect the end of the NS4D17002 universal interface with the feed pump. The external fuel is injected into the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com