Heat storage type graphene heating mural

A graphene and thermal storage technology, applied in ohmic resistance heating, heating element materials, electric heating devices, etc., can solve the problems of unable to store heat, unresolved, and unable to keep heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

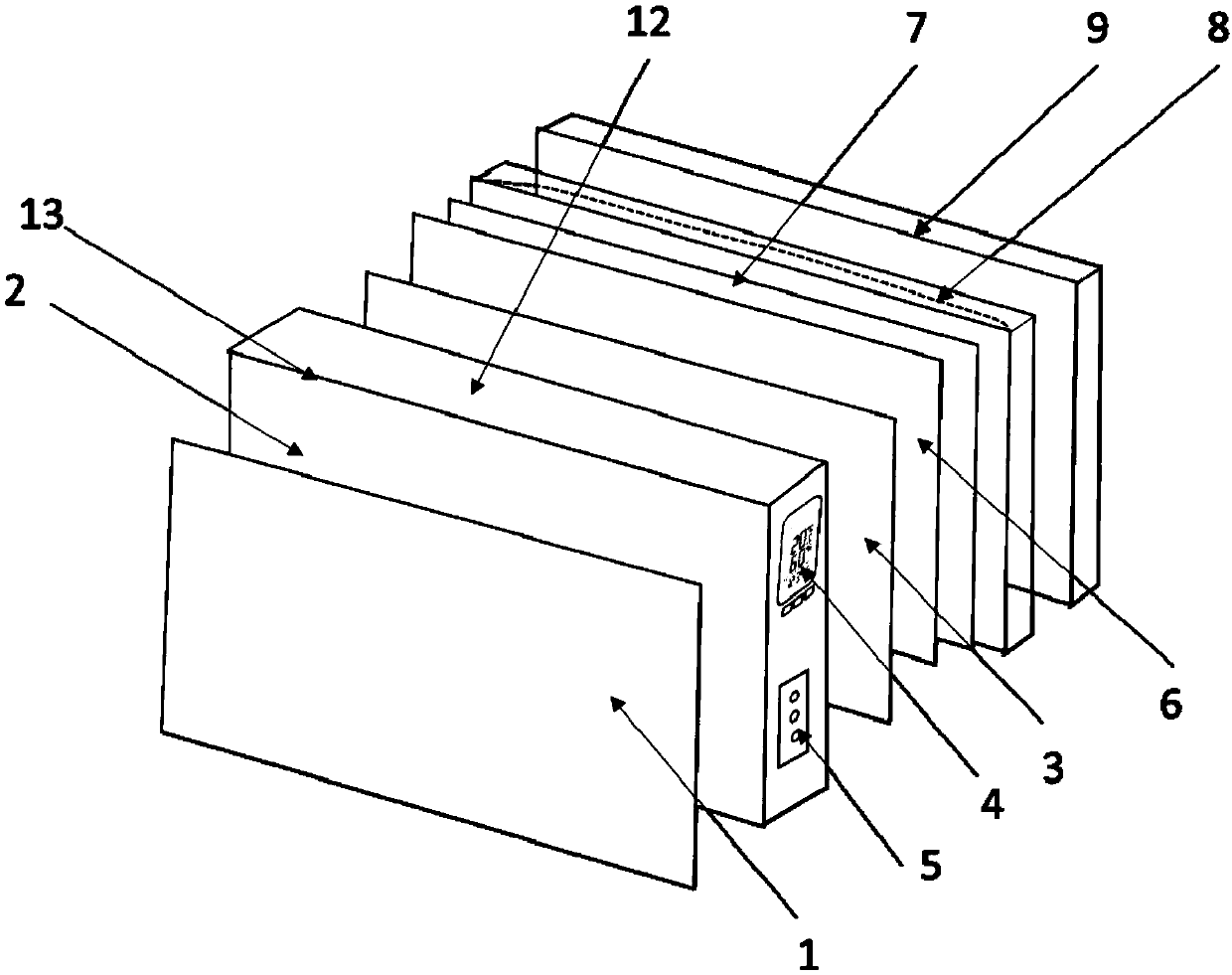

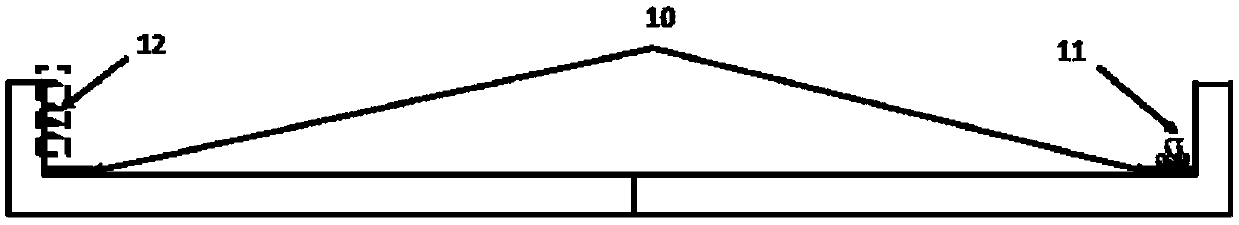

[0068] Such as Figure 1-3As shown, the regenerative graphene heating mural of the present invention mainly includes the following units: decorative picture layer 1, outer packaging layer 2, graphene functional layer 3, temperature control system 4, power supply module and interface 5, inner packaging layer 6, Phase change energy storage functional layer 7 , energy gathering reflective layer 8 , foam heat insulation layer 9 , conductive foil layer 10 , terminal post 11 , and installation buckle 14 .

[0069] Such as figure 1 , 3 The heating concave surface of the outer packaging layer 2 shown is the inner surface, and the other side is the outer surface, the decorative picture layer 1 is printed on the outer surface of the outer packaging layer 2, and the conductive foil layer 10 is laid on the edges of the two long sides of the inner surface of the outer packaging layer 2 , the conductive foil layer 10 is fixed with a terminal 11, the graphene functional layer 3, the inner ...

Embodiment 2

[0105] In the specific implementation of this embodiment, the decorative picture layer 1 adopts the plane picture formed by the method of inkjet painting;

[0106] The outer packaging layer 2 is a U-shaped plate with a length of 120 cm, a width of 60 cm, and a thickness of 6 mm, which is formed by pressing 10 wt% glass fiber and ethylene-chlorotrifluoroethylene copolymer (ECTFE);

[0107] The graphene functional layer 3 is a thin film with a thickness of 100 μm formed by the graphene CHR01 coating of Deyang Carbon Technology Co., Ltd. on the inner surface of the outer packaging layer 2 by brushing;

[0108] The temperature control system 4 has a temperature controllable range of 25-100°C. The temperature control module used is Pinyi PY-SM5, the humidity test module is AR837, the power meter is Risym-1 module, and the touch display is XG028. And through the USB port to achieve mutual connection;

[0109] The power supply module and the interface 5 are 120C02 card type sockets;...

Embodiment 3

[0118] In the specific implementation of this embodiment, the decorative picture layer 1 is a plane picture printed by printing;

[0119] The outer packaging layer 2 is a U-shaped plate with a length of 120 cm, a width of 60 cm, and a thickness of 2 mm, which is formed by pressing 5 wt% carbon fiber and polyether ether ketone (PEEK) resin;

[0120] The graphene functional layer 3 is a film with a thickness of 300 μm formed on the inner surface of the outer packaging layer 2 by spraying the nano water-based spray heat dissipation coating of Dongguan Zhongke Zhiheng New Materials Co., Ltd.;

[0121] Temperature control system 4 has a temperature controllable range of 25-100°C. The temperature control module used is ANTHONE900U, the humidity test module is Jianda Renke COS-04, the power meter is Xiya D52-2048 module, and the touch display is UE035HV-RN40-L006 type, and realize mutual connection through serial port;

[0122] The power supply module and the interface 5 are AC-03 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com