Prefabricated crack hydraulic fracturing, roof-cutting and pressure-relief construction method and drilling machine

A technology of roof cutting, pressure relief and hydraulic fracturing, which is applied to earthwork drilling, rotary drilling rigs, drilling equipment and methods, etc., and can solve problems such as poor safety, large consumption of explosives, and pollution of the underground operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The specific embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

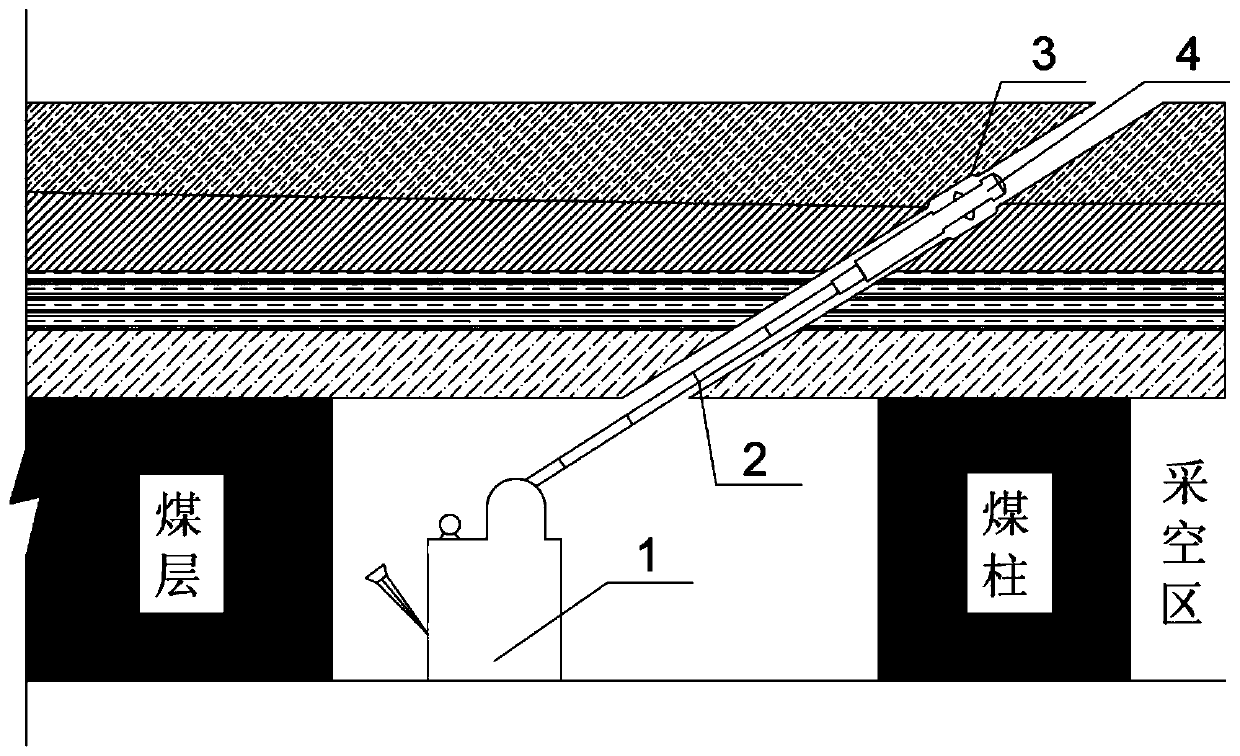

[0032] refer to Figure 1-Figure 6 , the construction method of pre-fracture hydraulic fracturing for roof cutting and pressure relief, comprising the following steps:

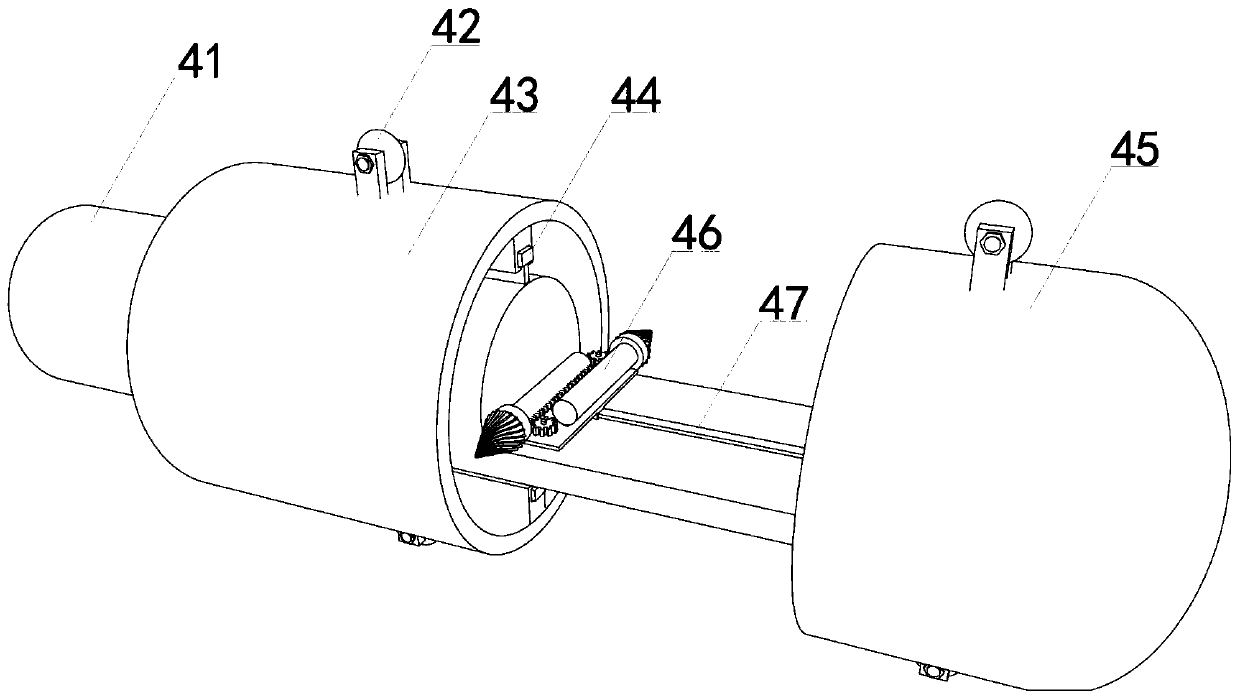

[0033] S1. The roof above the coal pillar is drilled at a certain interval, and the borehole spacing should be controlled between 15 meters and 30 meters; figure 2 The special drill bit 4 constructs the pre-crack 3. The auger bit 46 rotates at high speed driven by the small motor built in the connecting rod 463. Driven by the connecting rod 463 and the rotating gear 464, it can vertically translate the track for expansion and contraction. At the same time, the drill bit 46 can pass through the translation platform. The translation track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com