Enterprise energy operation efficiency analysis method and device

A technology of operation efficiency and analysis method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high energy consumption and waste, and achieve the effect of accurate operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

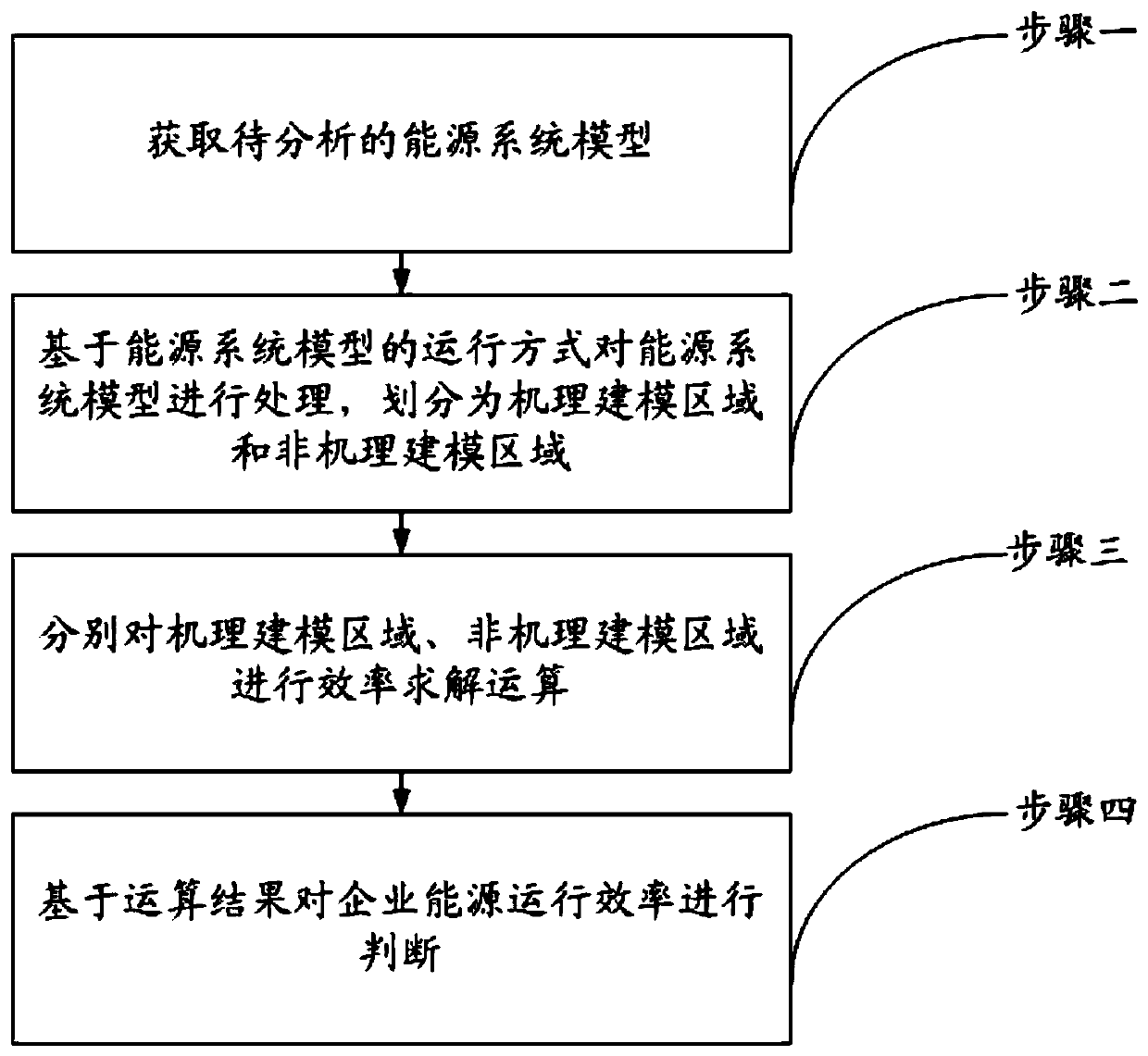

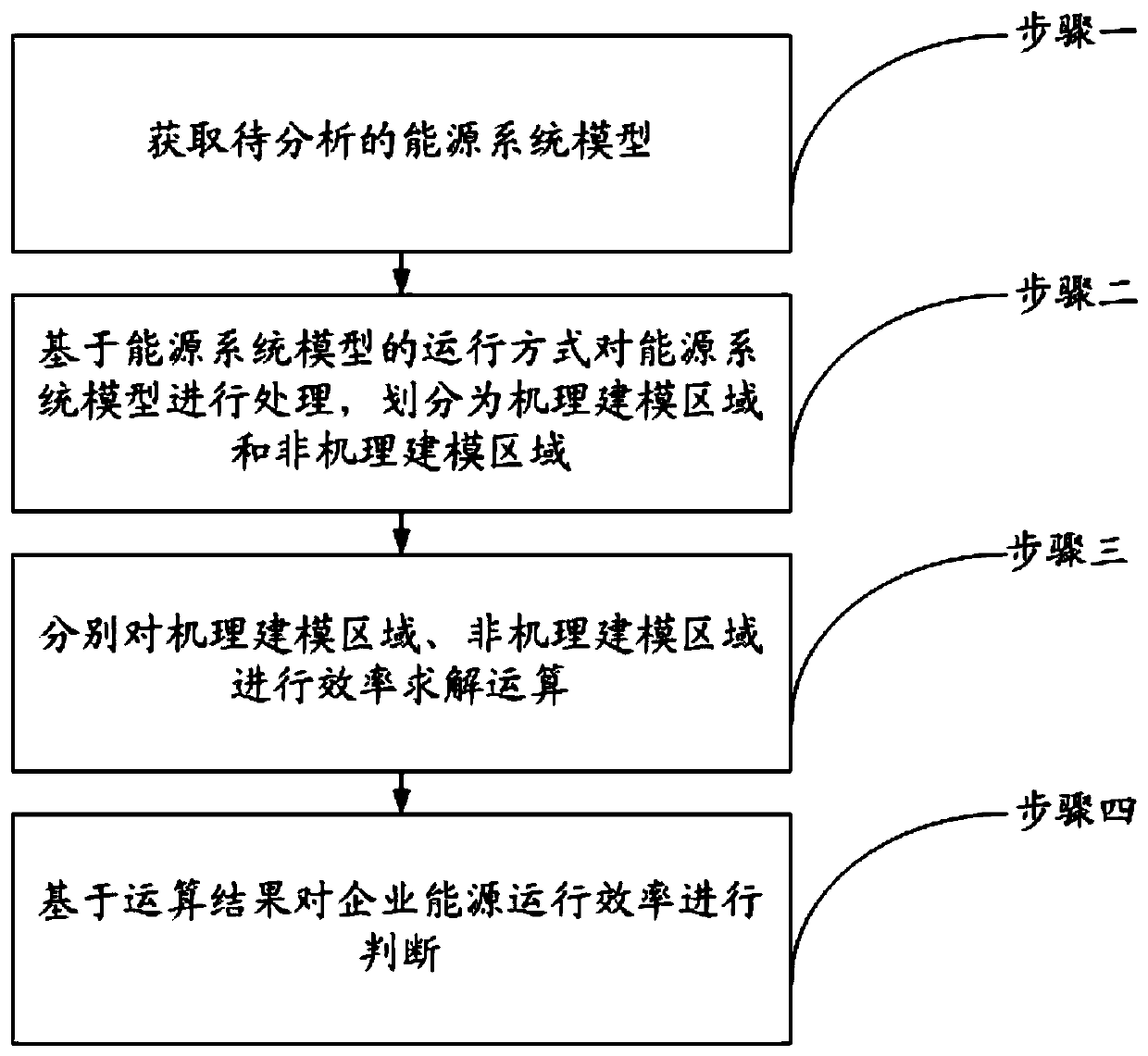

[0048] This application proposes an analysis method for the energy operation efficiency of enterprises, such as figure 1 As shown, the analysis method specifically includes:

[0049] Step 1, obtaining the energy system model to be analyzed;

[0050] Step 2, process the energy system model based on the operation mode of the energy system model, and divide it into a mechanism modeling area and a non-mechanism modeling area;

[0051] Step 3: Carry out efficiency calculation calculations for the mechanism modeling area and the non-mechanism modeling area respectively;

[0052] Step 4, judge the energy operation efficiency of the enterprise based on the calculation results.

[0053] In implementation, the analysis method proposed in this application needs to process the energy system model of the enterprise and divide it into a mechanism modeling area and a non-mechanism modeling area. The reason why different regions are divided here is to perform differentiated efficiency calc...

Embodiment 2

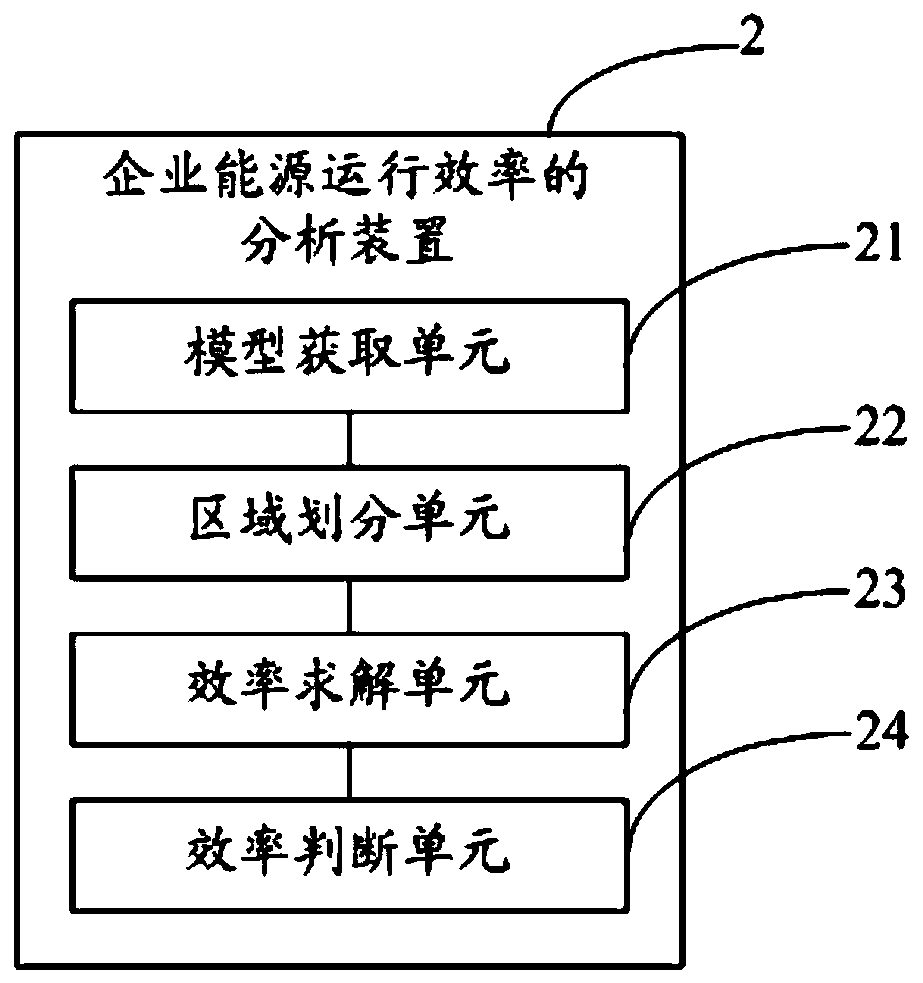

[0111] The embodiment of the present application also proposes an analysis device 2 for the energy operation efficiency of the enterprise, such as figure 2 As shown, the analysis device includes:

[0112] A model acquisition unit 21, configured to acquire an energy system model to be analyzed;

[0113] The area division unit 22 is configured to process the energy system model based on the operation mode of the energy system model, and divide it into a mechanism modeling area and a non-mechanism modeling area;

[0114]The efficiency solving unit 23 is used to perform efficiency solving operations on the mechanism modeling area and the non-mechanism modeling area respectively;

[0115] The efficiency judging unit 24 is used to judge the energy operation efficiency of the enterprise based on the calculation results and the historical efficiency data of the energy system model.

[0116] In implementation, the analysis method proposed in this application needs to process the ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com