High-efficiency rotating steam heating system based on space reciprocating cycle

A heating system, high-efficiency technology, applied in heat recovery systems, indirect heat exchangers, energy-saving heating/cooling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

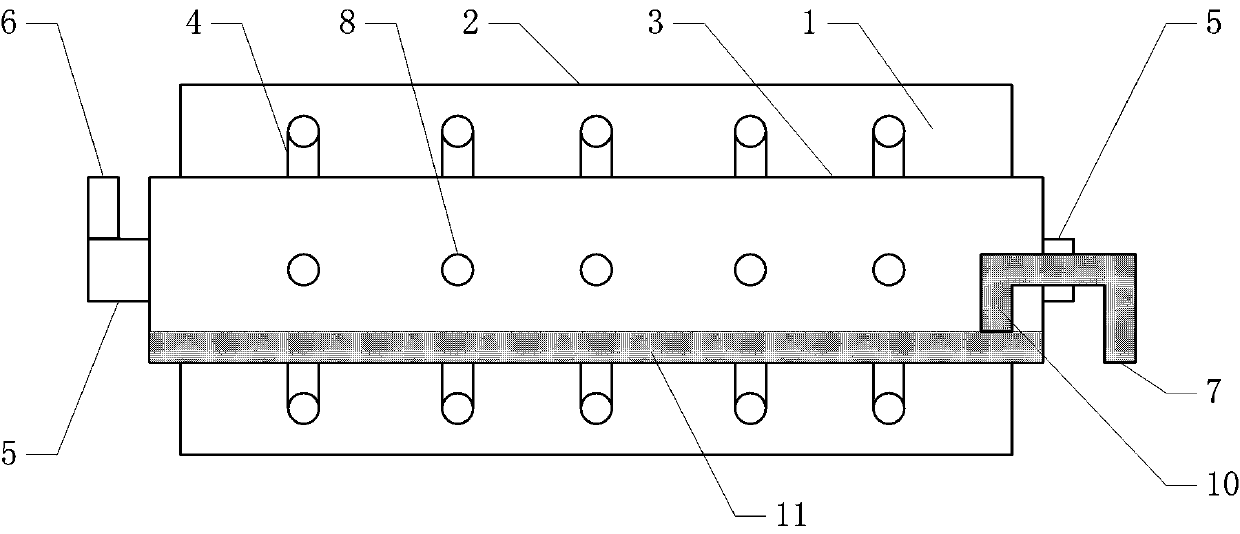

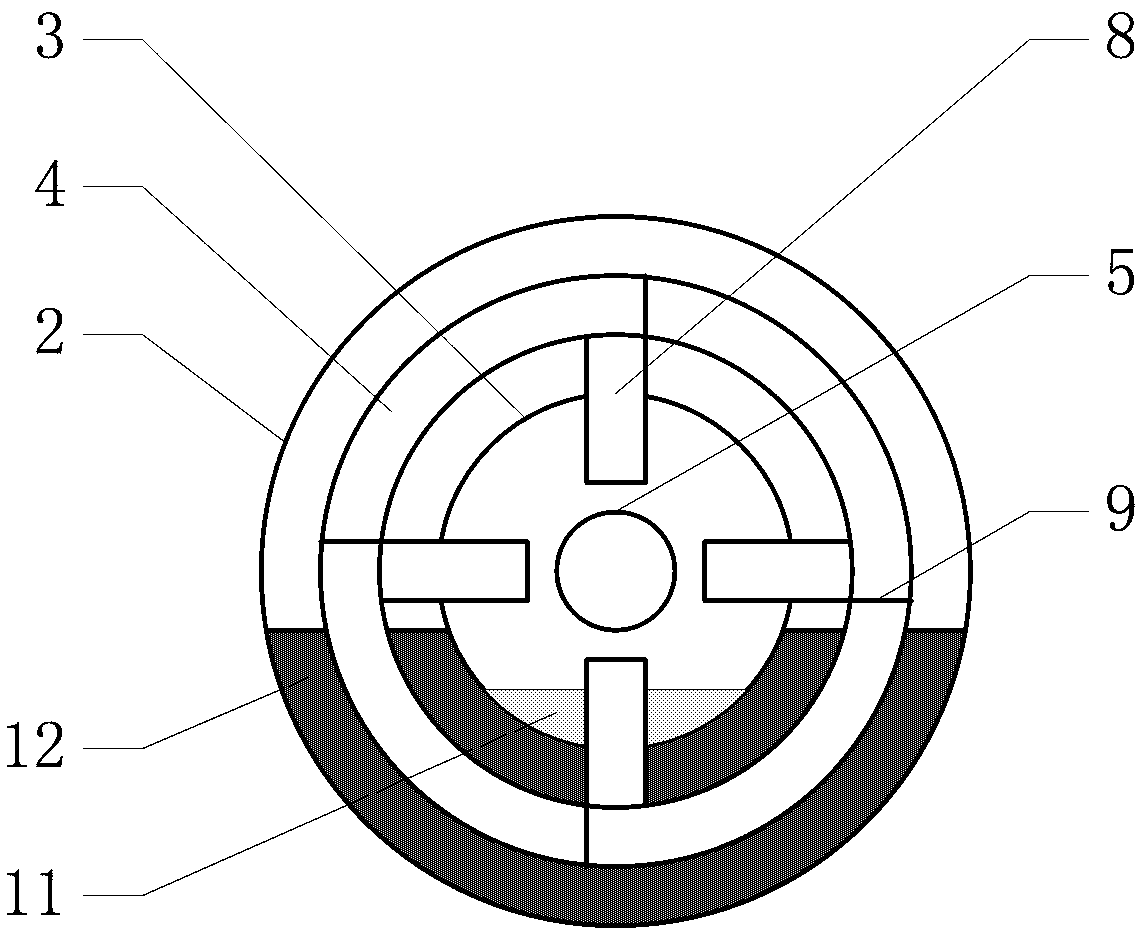

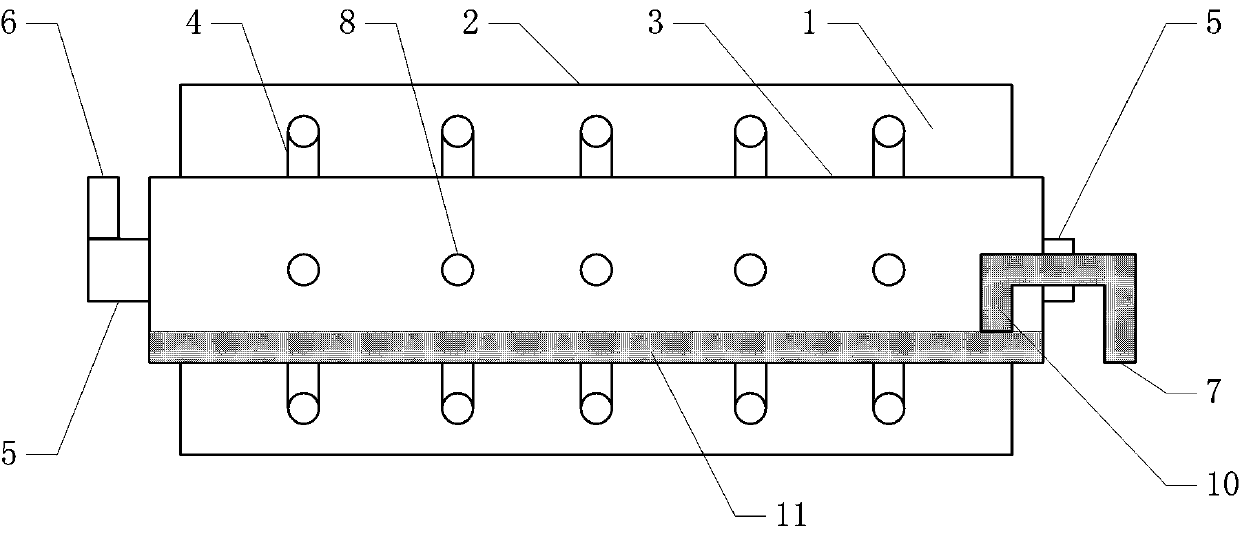

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] Such as figure 1 Shown is a side view of a high-efficiency rotary steam heating system based on space reciprocating circulation, figure 2 Shown is a cross-sectional view of a high-efficiency rotary steam heating system based on spatial reciprocating circulation. The high-efficiency rotary steam heating system based on space reciprocating circulation includes a steam heating device (1), a housing (2), a heating main shaft (3), a heating auxiliary (4), a stationary shaft (5), and a steam inlet ( 6), water outlet (7), connecting pipe (8), closed baffle (9), the heating accessory (4) is a single-layer hollow heating coil, or it can be multi-layer concentric parallel connection, sharing the same connecting Tube (8) and closing baffle (9).

[0024] figure 1 Among them, the outside of the steam heating device (1) is a hollow cylindrical shell (2), the heating mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com