Directly-buried composite cable

A composite cable and direct burial technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as being cut, unsafe cables, and cable deformation, so as to avoid shearing, improve the compression resistance of the top, and increase shock absorption ability and the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

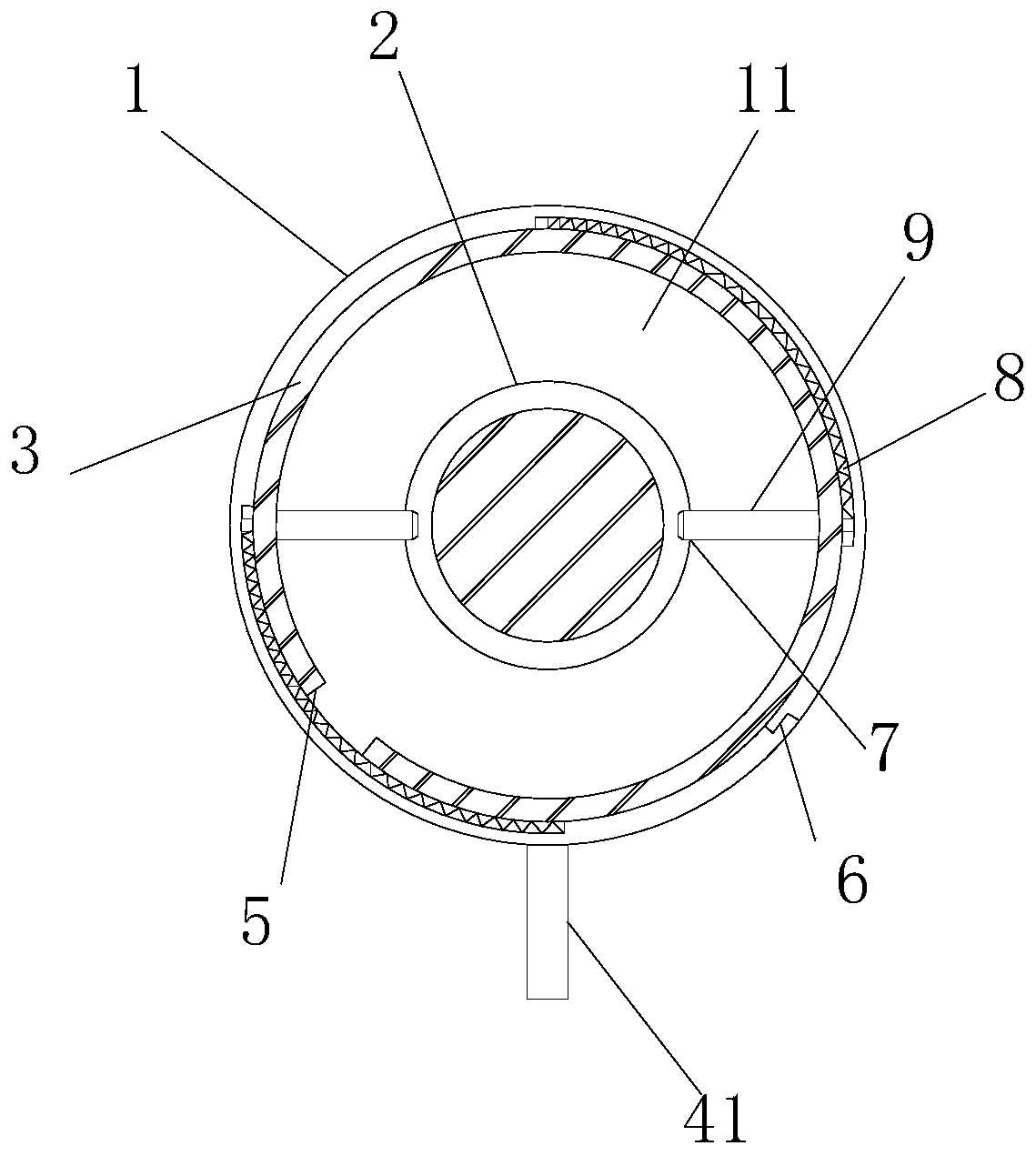

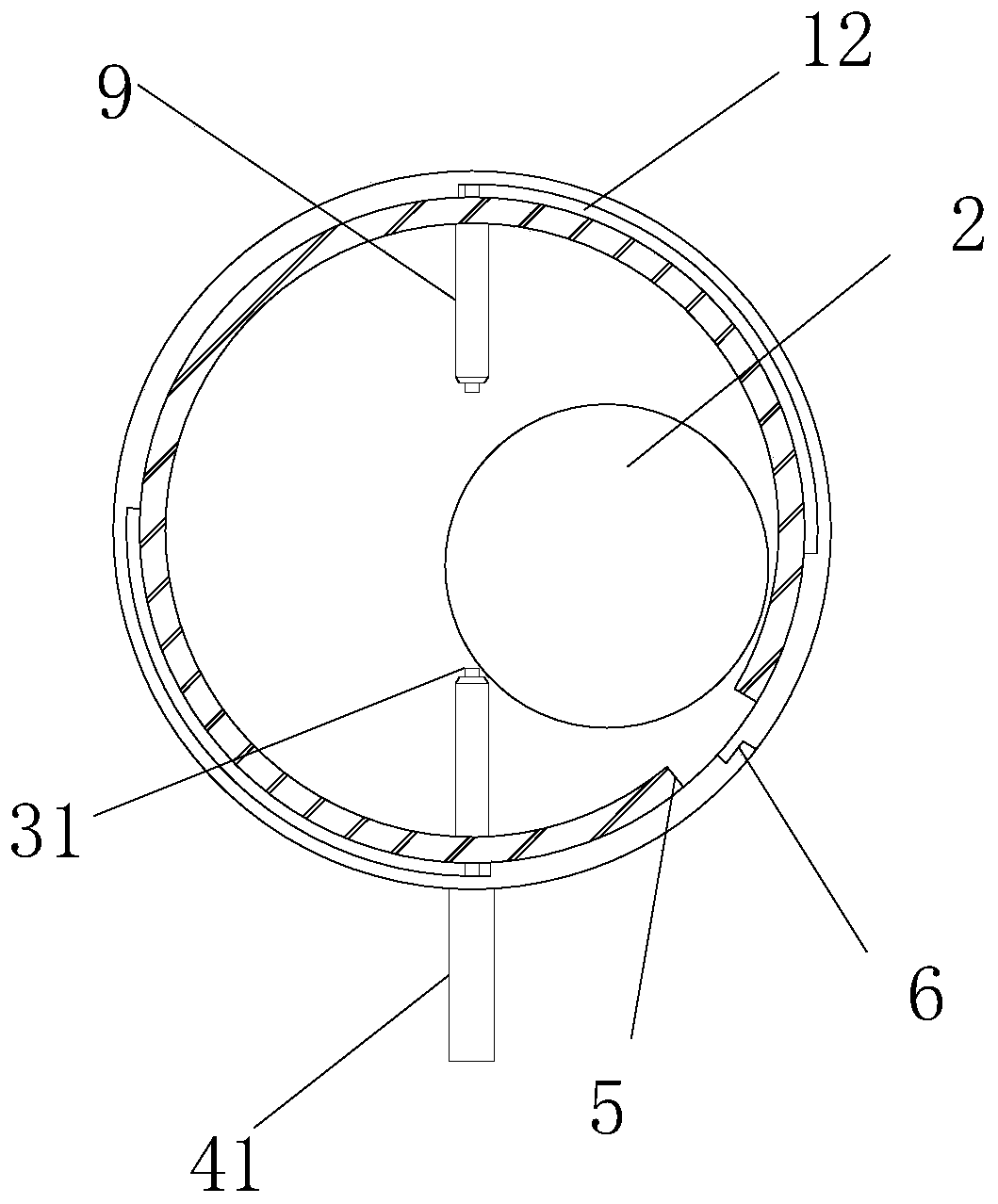

[0019] Such as figure 1 As shown, the direct-buried composite cable includes the cable main body. The position of the cable main body must be fixed to prevent deviation when it is sheared by the top. Therefore, it is necessary to set more than one positioning insert rod 41 at the bottom of the cable main body. The insertion rod 41 is inserted into the ground to locate the main body of the cable;

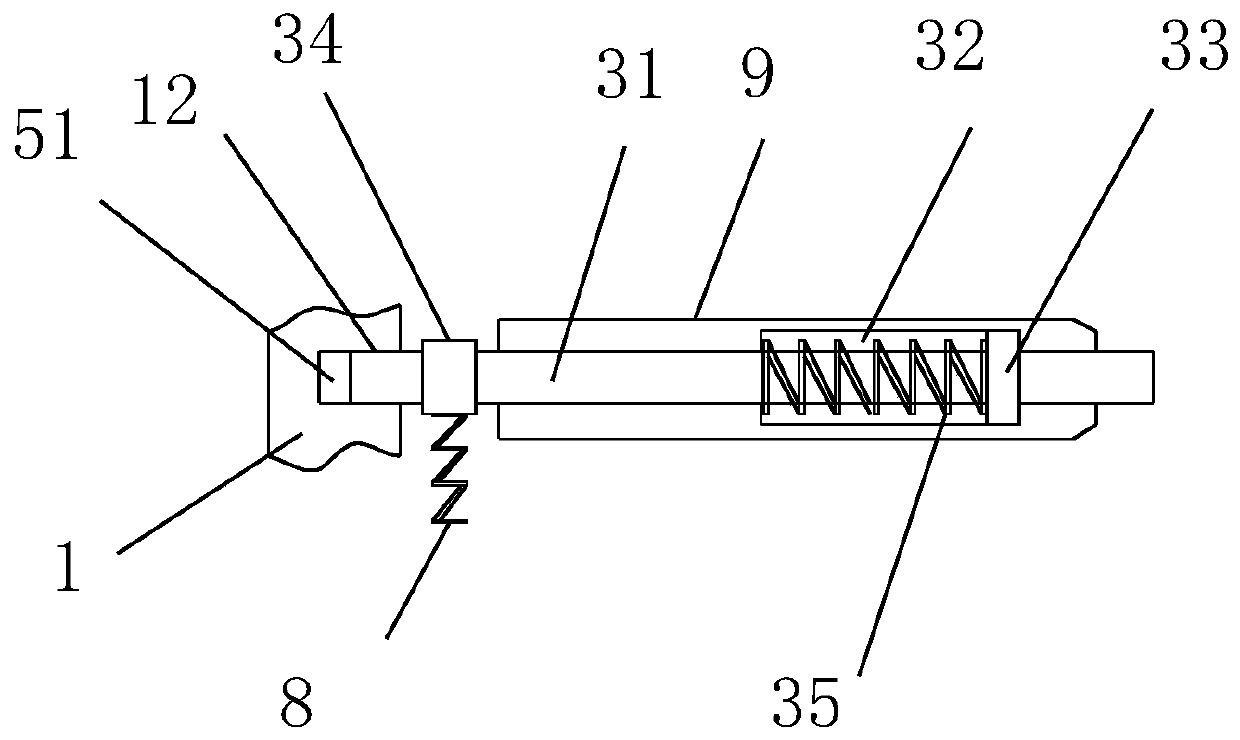

[0020] In this embodiment, the cable main body includes an outer coating layer 1, and the outer coating layer 1 has an installation cavity 11 inside, and the inner core wire 2 is installed in the installation cavity 11, and the inner wall of the installation cavity 11 is provided with a rotating layer 3, and the outer wall of the rotating layer 3 Close to the inner wall of the installation cavity 11, the symmetrical surface of the installation cavity 11 is equidistantly provided with more than one slide rail groove 12 along the length direction of the outer layer, and a spring 8 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com